Quick detection method for fine aggregate water content

A detection method, fine aggregate technology, applied in the direction of using material absorption and weighing, etc., can solve the problems affecting the quality of concrete slump, and achieve the effect of shortening the hidden danger of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A kind of rapid detection method of moisture content of fine aggregate, it comprises

[0020] Step 1: Fine aggregate sampling, weighing the fine aggregate with a representative sample m 0 , accurate to 1g;

[0021] Step 2: Put all the fine aggregate weighed in Step 1 into a container with a predetermined scale line, add water to about below the scale line, stir to remove air bubbles, add water again to the scale line, and weigh its mass m 1 , accurate to 1g;

[0022] Step 3: Empty and wash the scaled container containing fine aggregate, fill it with water to the scaled line again to ensure that there are no air bubbles on the surface, and weigh its mass m 2 Accurate to 1g;

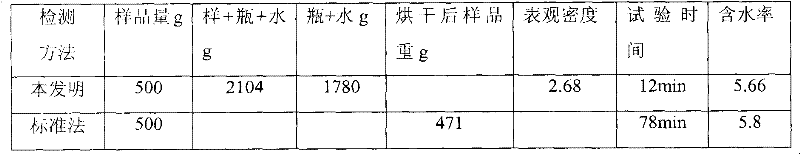

[0023] Step 4: Calculate according to the formula:

[0024] Moisture content of fine aggregate (%) = (m 0 -(m 0 +m 2 -m 1 )×γ s )×100% / m 0

[0025] In the formula: m 0 - To test the sample quality, not less than 350g and accurate to 1g

[0026] m 1 - When adding water to 1L after loadi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com