Circulating tin plating process and device

A tinning device and circulation technology, applied in hot-dip plating process, metal material coating process, coating, etc., can solve the problems of limiting the production speed of tinning line, atmospheric environmental pollution, waste, etc., and achieve the reduction of liquid tin The effect of dissolved oxygen, ensuring product quality, and reducing waste of tin slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A cyclic tin plating process, it comprises the following steps:

[0049] Step 1, the copper wire enters the downwardly inclined annealing furnace tube from the inlet of the annealing furnace tube, and performs high-temperature annealing in the high-temperature annealing zone of the annealing furnace tube; liquid tin is pumped from the storage device into the end of the annealing furnace tube near the exit, and the The liquid level of the storage device is lower than the outlet of the furnace tube of the annealing furnace;

[0050] Step 2, the copper wire enters the annealing cooling zone of the annealing furnace tube for preliminary cooling, but the temperature of the copper wire is still higher than the temperature of the liquid tin pumped into the annealing furnace tube;

[0051] Step 3, the copper wire is in contact with liquid tin and enters the tin-in heating zone of the annealing furnace tube for pre-tinning. The oxygen content of the liquid tin in the tin-in heat...

Embodiment 2

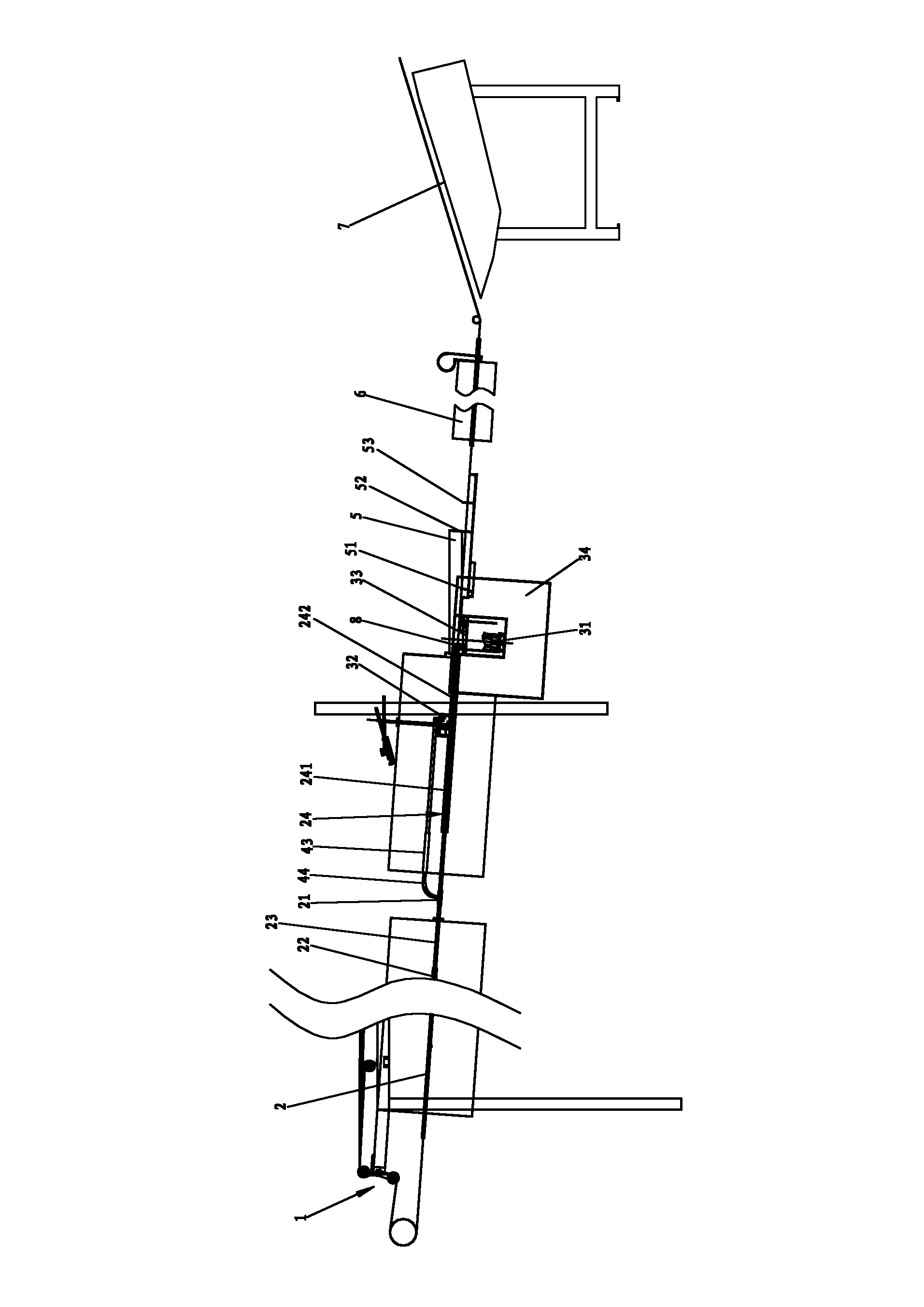

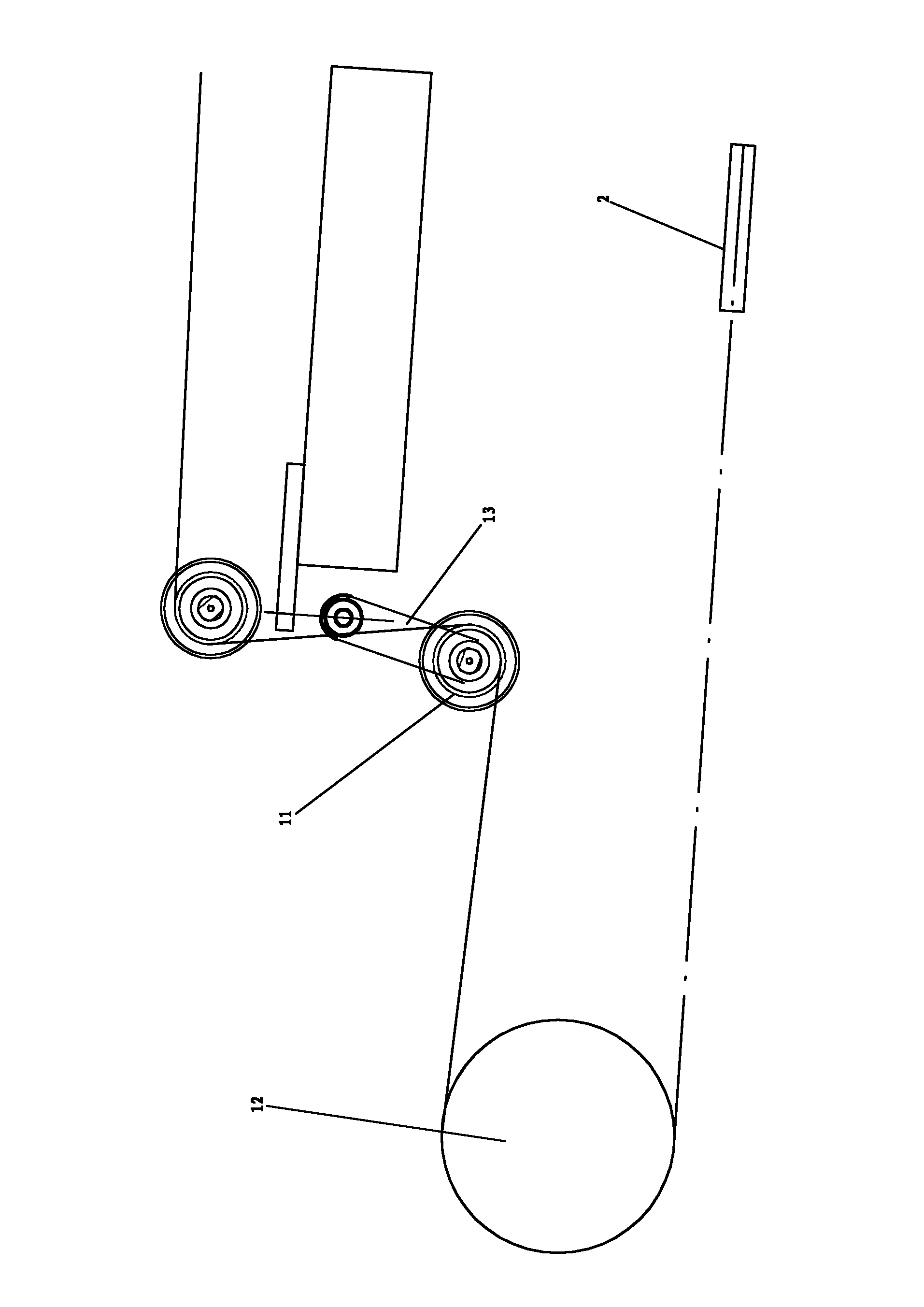

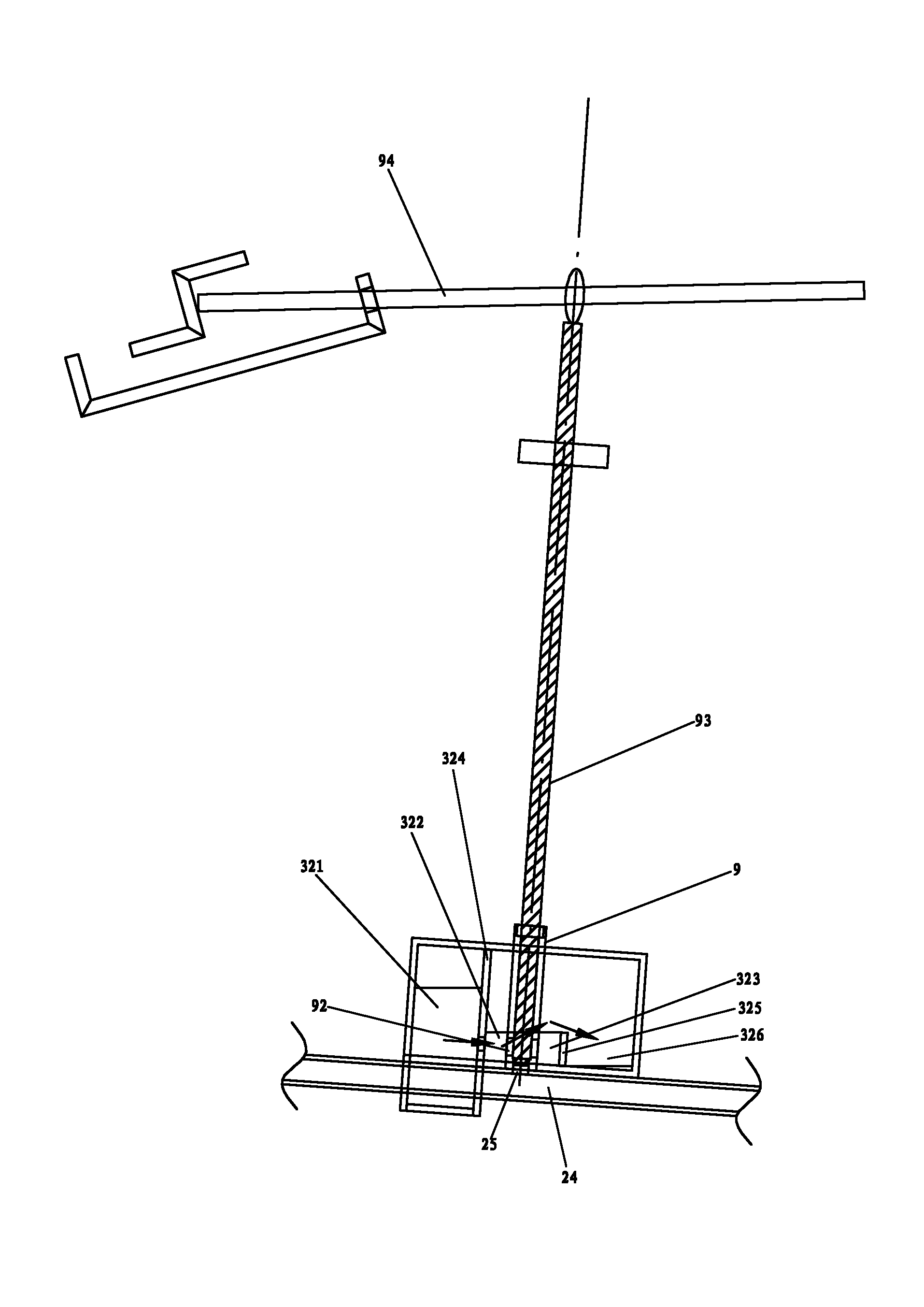

[0063] Such as Figure 1 to Figure 8 As shown, a kind of device that implements a kind of circulation type tin plating process of the present invention, it comprises constant speed and buffer device 1, the annealing furnace furnace tube 2 that passes through the annealing furnace furnace body, communicates with the annealing furnace furnace tube 2 and The furnace pipe joint 21 that can be introduced into the protective gas, the annealing furnace furnace pipe 2 is inclined downward from the inlet to the outlet; it also includes a liquid tin circulation system, a protective gas circulation system, a water cooling device 5, a drying device 6 and a cooling air Bucket 7; from the entrance, along the annealing furnace tube 2, a high-temperature annealing zone 22, an annealing cooling zone 23, a tin-in heating zone 241 and a tin-out heating zone 242 are arranged in sequence, and the annealing furnace tube 2 is heated in the tin-in District 241 and the tinning heating zone 242 are tin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com