Compound-type prestressed anchor cable structure and construction method thereof

A prestressed anchor cable and composite technology, applied in the direction of foundation structure engineering, excavation, sheet pile walls, etc., can solve the problems of insufficient durability, achieve good anti-corrosion effect, reasonable structure, and improve the overall anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

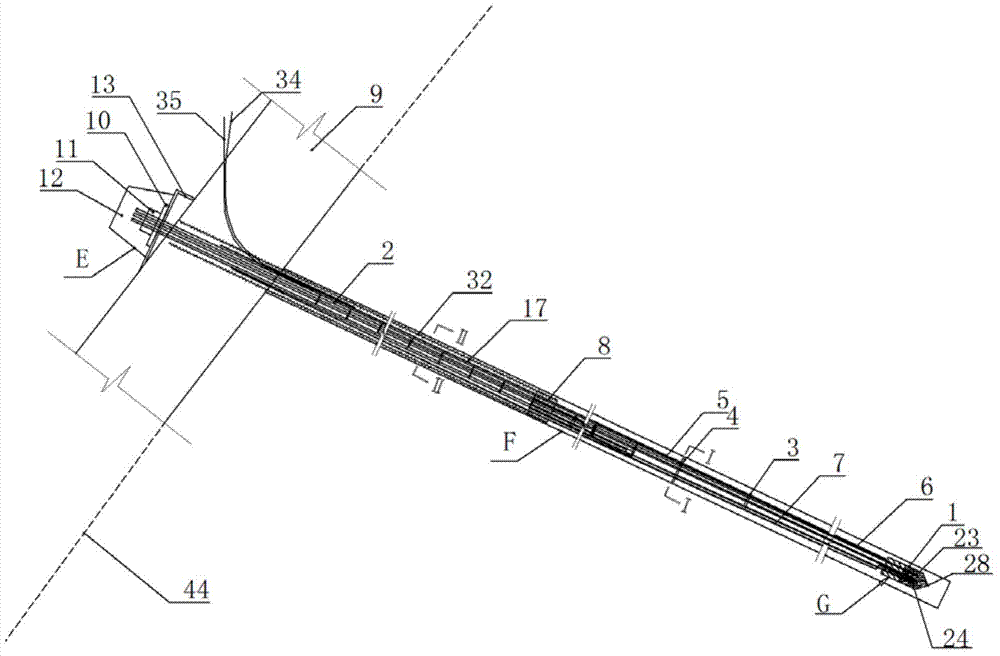

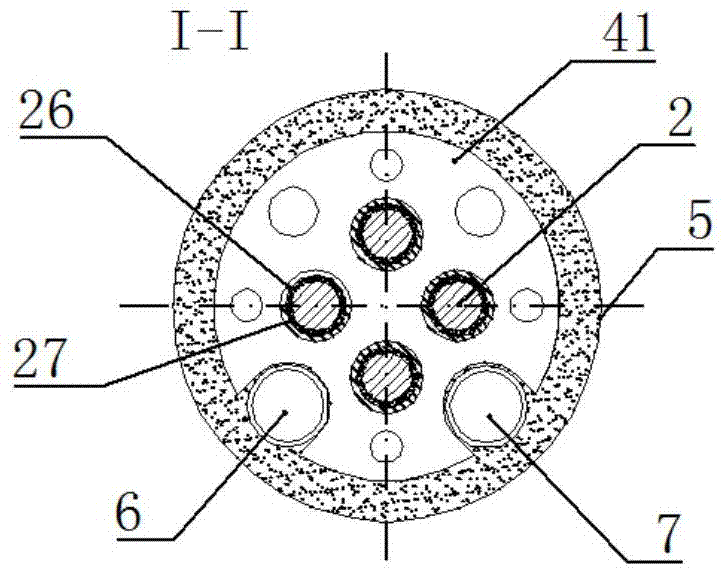

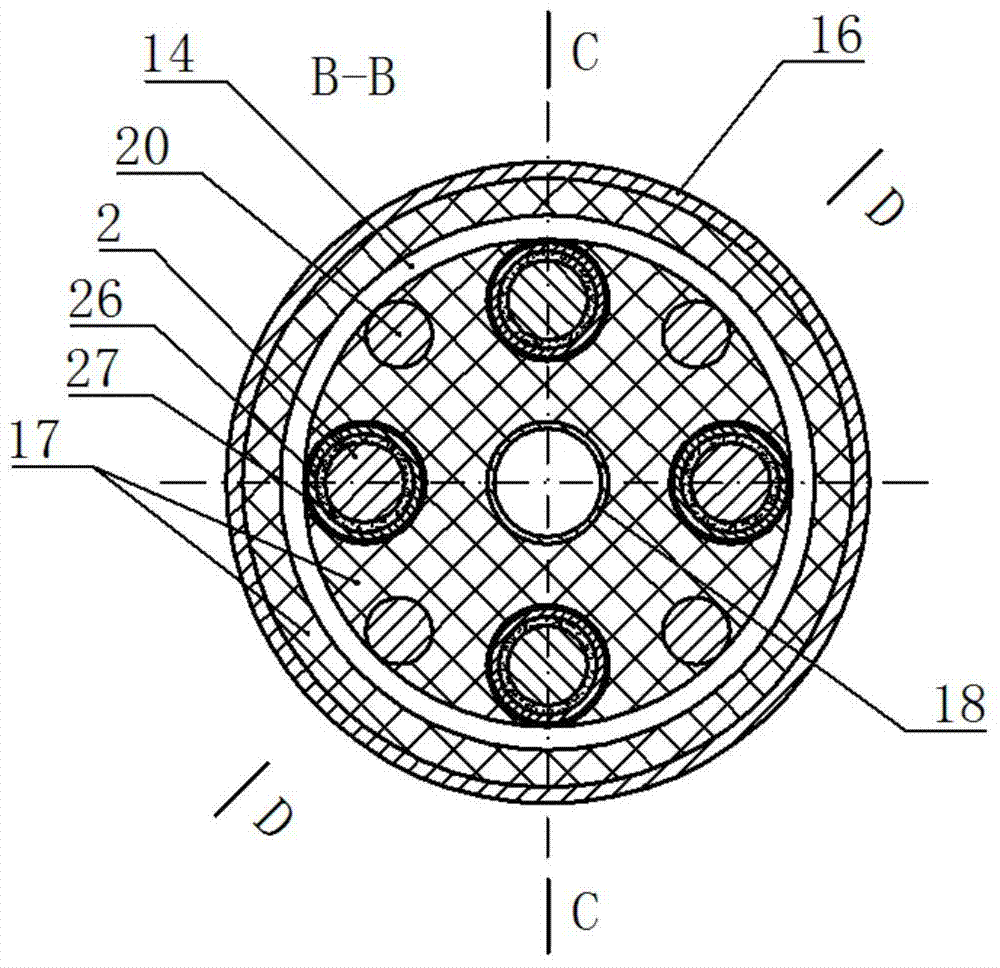

[0061] see Figure 1-Figure 11 , the composite anchor cable structure of the present invention includes a prefabricated inner anchor head 1, a steel strand 2, a hoop ring 3, a positioning frame 4, a drill hole 5, a primary grouting pipe 7, a secondary grouting pipe 6, and a third grouting pipe 34. Bellows 32, prefabricated grouting body 17 and outer anchoring end E are described as follows:

[0062] 1. Prefabricated inner anchor head 1:

[0063] The prefabricated inner anchor head 1 includes a carrier G, an extrusion sleeve 23, an extrusion spring 24 and a positioning mechanism. The carrier G includes: a steel pressure bearing plate 15 is provided at the bottom of the stainless steel pipe 21 of the anchor head. The center of the anchor head stainless steel pipe 21 passes through the central grouting pipe 18, and a prefabricated grouting body 17 and a threaded stress rib 20 are arranged on the part above the steel bearing plate 15. Around the center of the prefabricated grouti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com