Medium-and-low speed magnetic levitation railway low route continuous arched supporting rail beam structure and construction method

A technology for low-level lines and maglev railways, which is applied to the continuous arched rail-bearing beam structure and construction of low-level lines of medium and low-speed maglev railways, can solve problems such as difficulty in maintenance, difficulty and limitations, and avoid potential quality problems. Less concrete consumption and the effect of solving cumbersome construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

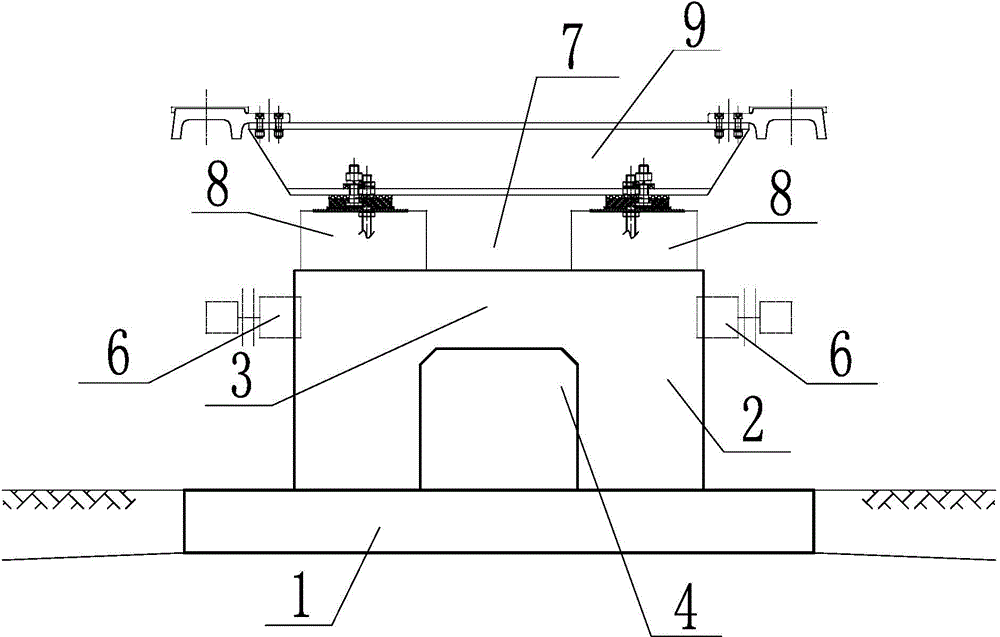

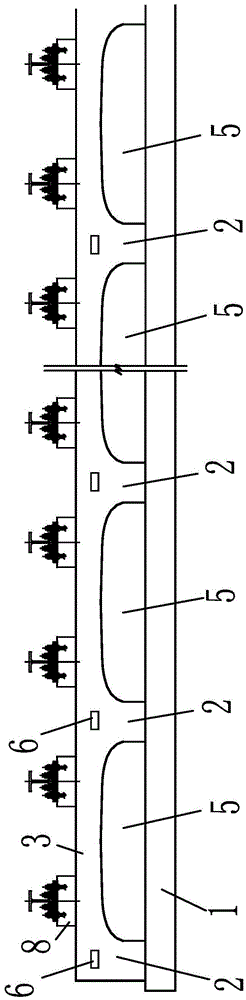

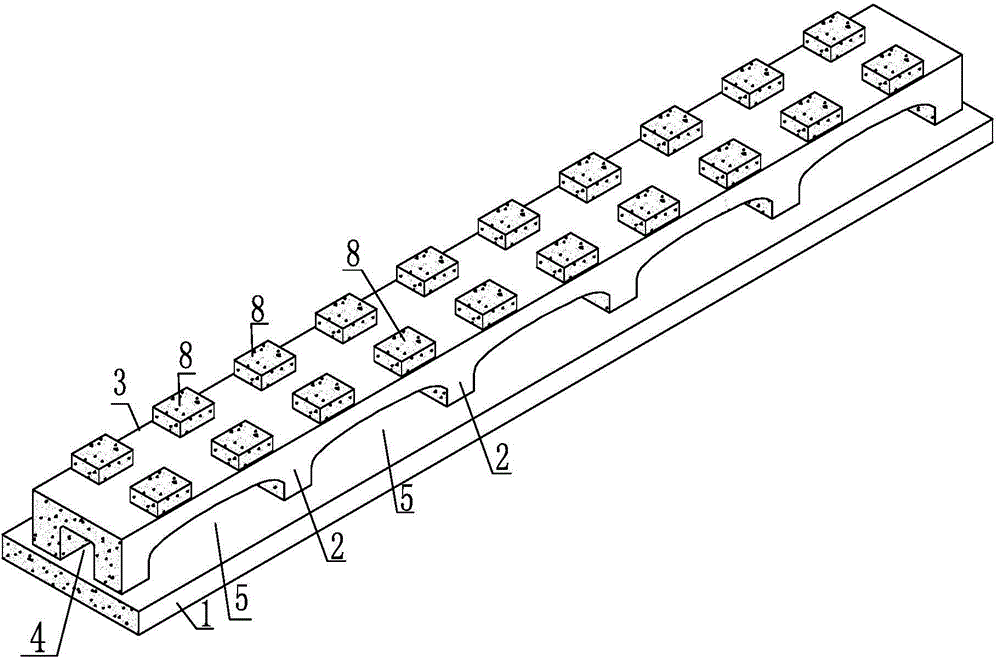

[0033] Such as figure 1 The continuous arched rail bearing beam structure of the low-lying line of the medium-low speed maglev railway shown in the figure includes a reinforced concrete base plate 1, a rail row 9, and multiple rows of rail bearing platforms 8 arranged along the direction of the track line. Each row of track bearing platforms 8 includes There are two left and right track support platforms 8, and between the left and right track support platforms 8 in each row of track support platforms 8 is a transponder installation position 7, which also includes a reinforced concrete top plate 3, two side guide rail bracket 6, a plurality of reinforced concrete arch columns 2 arranged at equal intervals along the direction of the track line on the reinforced concrete floor 1, wherein the bottom of the reinforced concrete roof 3 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com