Fast cured thermal conductive adhesive and preparation method thereof

A technology of thermally conductive adhesive and thermally conductive particles, used in adhesives, non-polymer organic compound adhesives, non-polymer adhesive additives, etc., can solve the problems of slow curing, slow curing speed, improper ratio, etc. The effect of interface wetting ability, preventing quality problems and saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

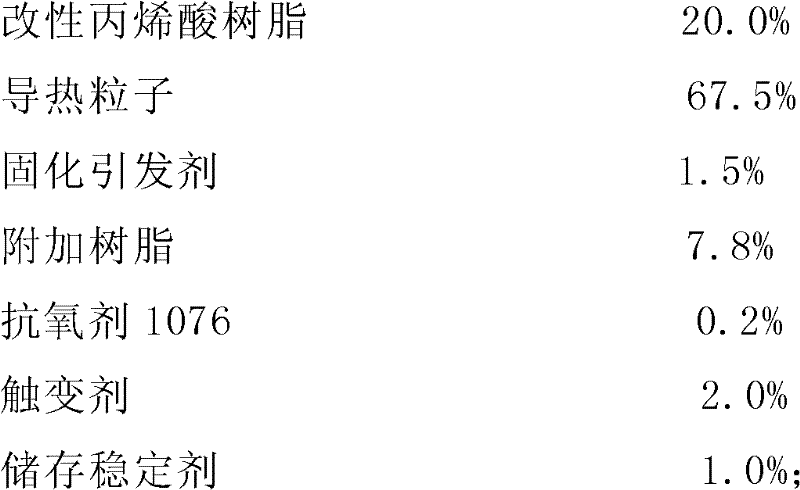

[0041] The components and weight percentages of the thermally conductive adhesive are as follows:

[0042]

[0043] The modified acrylic resin is tetrahydrofuryl methacrylate;

[0044] The thermally conductive particles are alumina particles with a particle size range of 3-5um;

[0045] The curing initiator is benzoyl peroxide tert-butyl;

[0046] The modified resin is methacrylate-butadiene-styrene copolymer;

[0047] The thixotropic agent is fumed silicon R720;

[0048] The storage stabilizer is 2,6-di-tert-butyl-p-cresol;

[0049] Specific preparation method:

[0050] Add modified acrylic resin, heat-conducting particles, modified resin, antioxidant 1076, and thixotropic agent into the planetary dynamic mixer according to the above formula ratio, and mix and stir evenly (stirring speed range, stirring time is about half an hour, and the obtained stirring mixture in paste form);

[0051] Pour it into a three-roller grinder and grind it 3 times until the mixture is c...

Embodiment 2

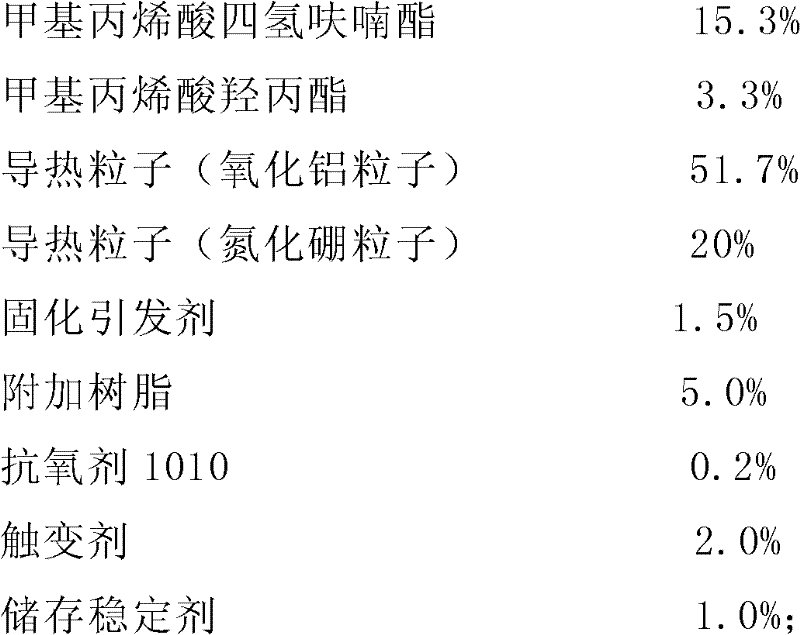

[0054] The components and weight percentages of the thermally conductive adhesive are as follows:

[0055]

[0056] The modified acrylic resin is a mixture of tetrahydrofuryl methacrylate and hydroxypropyl methacrylate;

[0057] The particle size range of thermally conductive particles boron nitride is 3um-10um, and the particle size range of thermally conductive particles alumina is 2um-5um;

[0058] Curing initiator is the mixture that the mass ratio of benzoyl peroxide and benzoyl tert-butyl peroxide is 2:1;

[0059]The additional resin is styrene-butadiene rubber;

[0060] The thixotropic agent is fumed silicon R720;

[0061] The storage stabilizer is a mixture of 2,6-di-tert-butyl-p-cresol and p-benzoquinone (mass ratio=1:1);

[0062] The preparation process is the same as in Example 1.

Embodiment 3

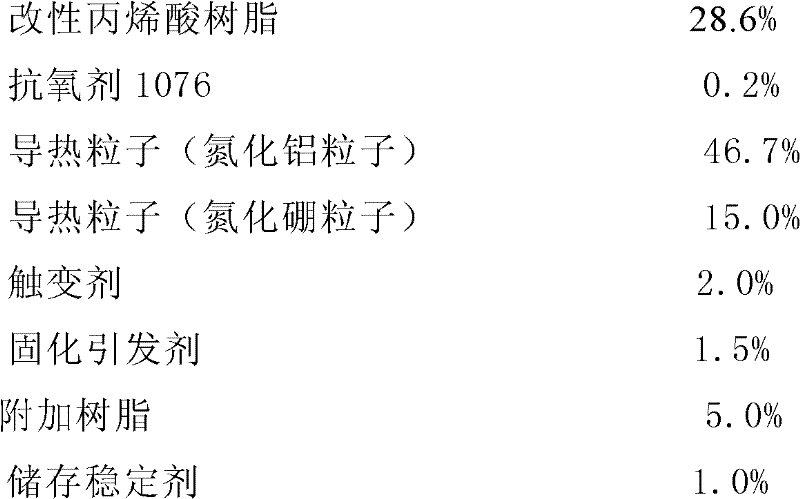

[0064] The components and weight percentages of the thermally conductive adhesive are as follows:

[0065]

[0066] The modified acrylic resin is a mixture of tetrahydrofuryl methacrylate and hydroxypropyl methacrylate in a mass ratio of 3:1;

[0067] The particle size range of thermally conductive particles boron nitride is 3um-10um, and the particle size range of thermally conductive particles alumina is 2um-5um;

[0068] Curing initiator is the mixture that the mass ratio of benzoyl peroxide and benzoyl tert-butyl peroxide is 2:1;

[0069] The additional resin is methacrylate-butadiene-styrene copolymer;

[0070] The thixotropic agent is fumed silicon R720;

[0071] The storage stabilizer is a mixture of 2,6-di-tert-butyl-p-cresol and p-benzoquinone (mass ratio=1:1);

[0072] The preparation process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com