Strip steel through-type shot blasting cleaning machine

A technology of shot blasting machine and strip steel, which is applied to the processing device of used abrasives, abrasive jetting machine tools, abrasives, etc. It can solve the problem of less special equipment for strip steel shot blasting cleaning, the impact of conveying devices on the cleaning effect, and the use of dust removal systems. Short cycle and other problems, to achieve better dust removal effect, better cleaning effect and wide range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

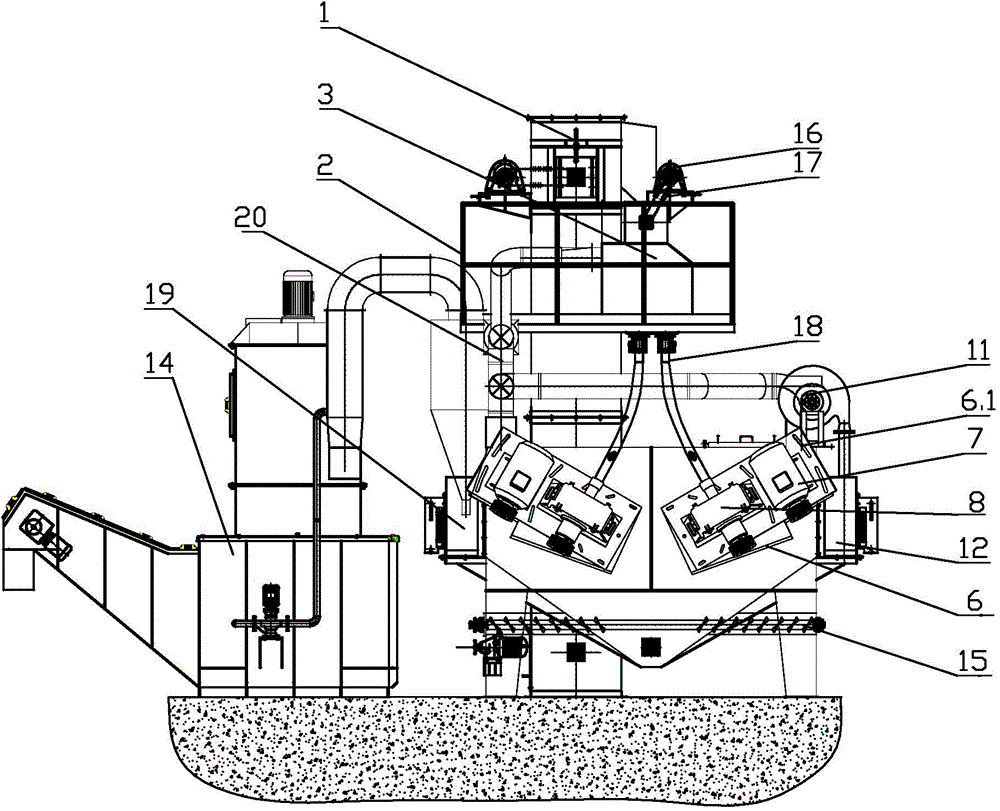

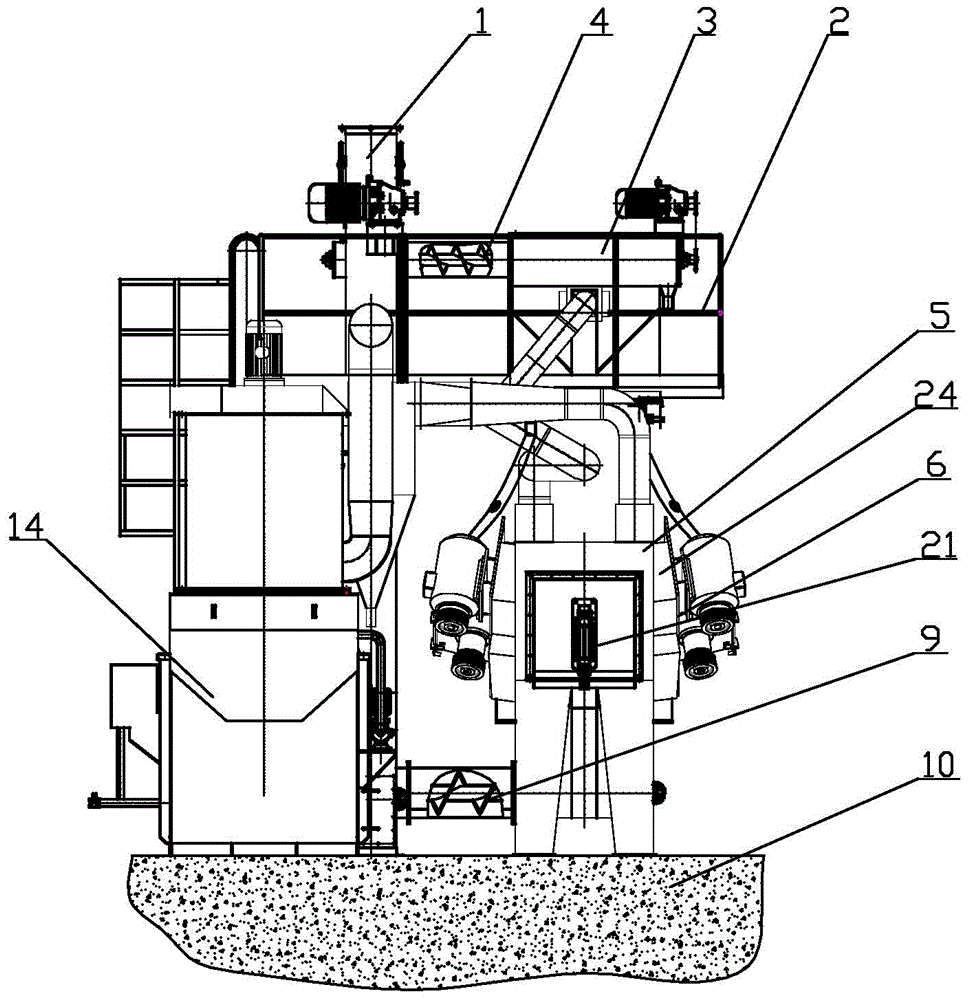

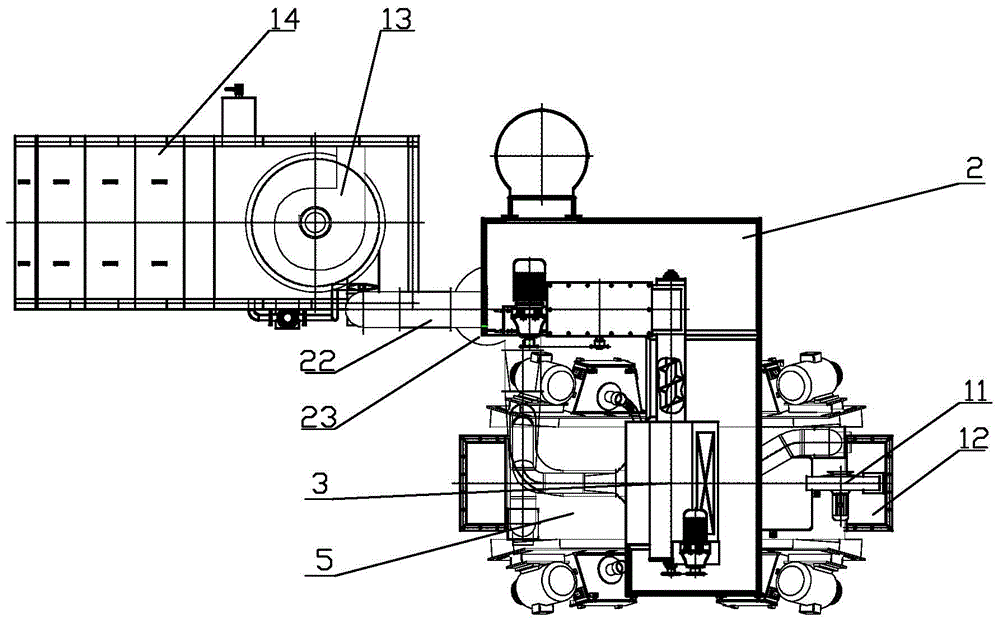

[0029] Such as Figure 1~10 As shown, the present invention mainly includes hoist 1, maintenance platform 2, shot sand separator 3, upper screw conveyor 4, cleaning chamber body 5, lower screw conveyor 9, base 10 and water curtain dedusting device 14, base 10, the hoist 1 and the maintenance platform 2 are fixed, and the pill sand separator 3 is fixed on the maintenance platform 2. The elevator 1 and the shot-sand separator 3 are connected by an upper screw conveyor 4, and the upper screw conveyor 4 sends the shot material at the upper end of the elevator 1 to the shot-sand separator 3 for separation of shot and sand.

[0030] Such as Figure 4 As shown, the hoist 1 includes a lifting frame 1.1, the upper and lower ends of the lifting frame 1.1 are respectively provided with a driving shaft 1.2 and a driven shaft 1.8, and a lifting belt 1.7 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com