Assembled oil-gas separator and oil-gas separation method thereof

An oil-gas separator and combined technology, which is applied to machines/engines, parts of pumping devices for elastic fluids, and parts of rotary piston type/oscillating piston type pumps, etc. Affect the energy-saving operation of the compressor, the limited capacity of the cyclone separator, etc., to achieve the effect of avoiding secondary entrainment, high working efficiency, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the drawings and embodiments.

[0024] Existing oil-gas separators for oil-injected compressors are usually separated by a combination of cyclones and filter elements, which have poor adaptability to compressors with a wide range of operating conditions. In addition, there are still oil droplets separated by high speed. The re-carrying of the air flow into the oil and gas mixture causes the problem of secondary entrainment. To this end, the present invention proposes the following combined oil and gas separator.

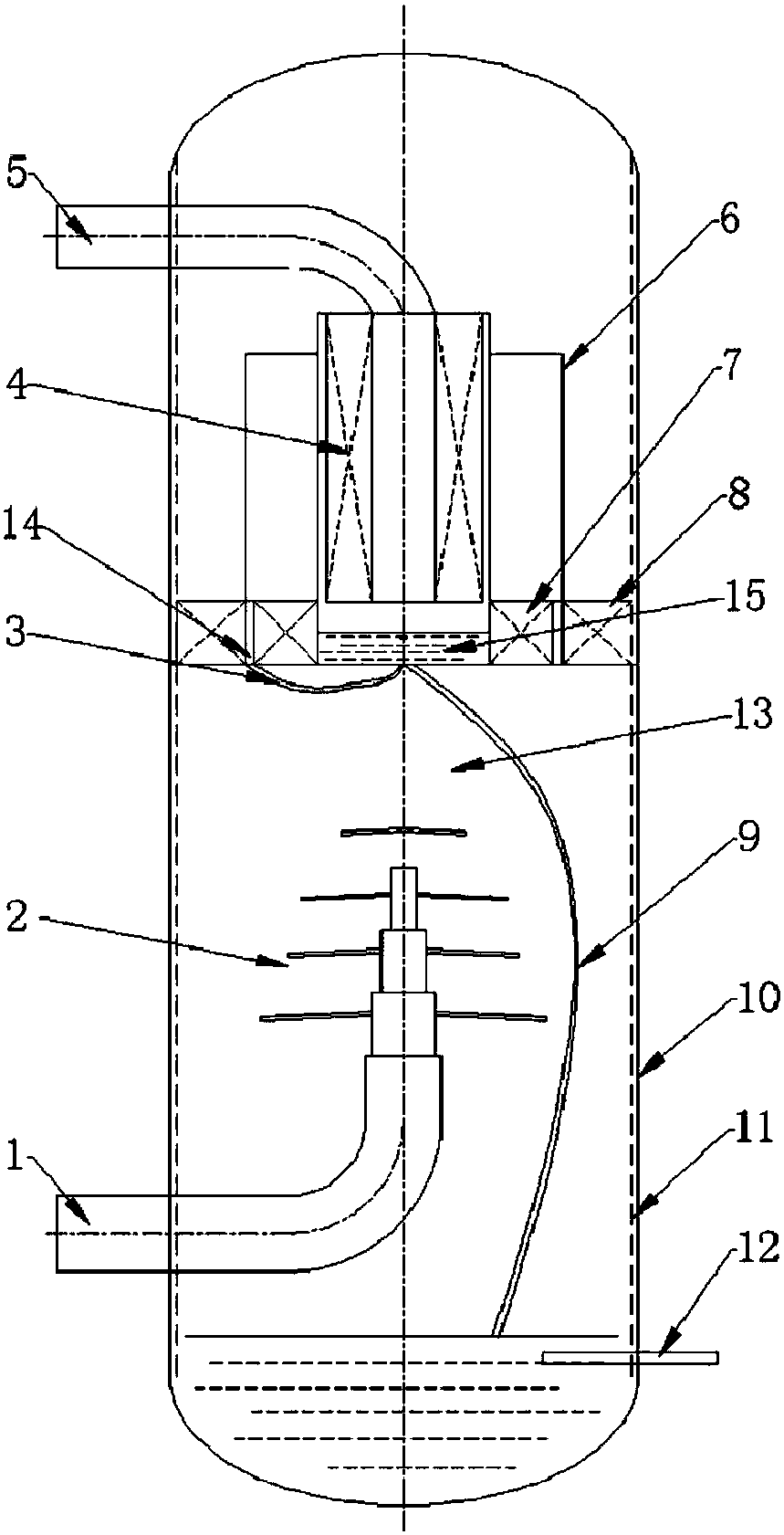

[0025] See figure 1 The combined oil and gas separator of the present invention includes a cylindrical cylinder body 10, the lower part of the cylinder body 10 is connected with a mixed gas inlet 1 and an oil outlet 12, the upper part of the cylinder body is connected with a clean gas outlet 5, and the cylinder body 10 has Tower-shaped preliminary separation device 2, inner cyclone 7 and ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com