Titanium dioxide photo-catalytic micro-reactor

A micro-reactor, titanium dioxide technology, applied in the field of high-efficiency TiO2 photocatalytic micro-reactor, can solve the problems of low mass transfer efficiency, small effective catalytic area, difficult catalyst recovery, etc., and achieves convenient and simple operation and post-processing, online and The effect of convenient offline detection and easy repeated use for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

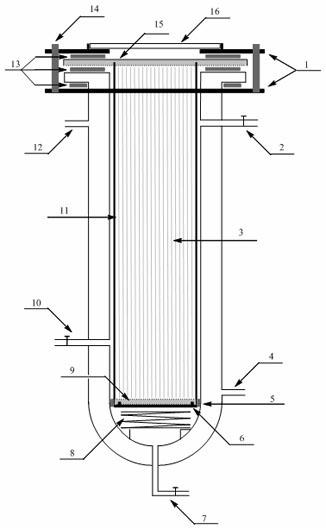

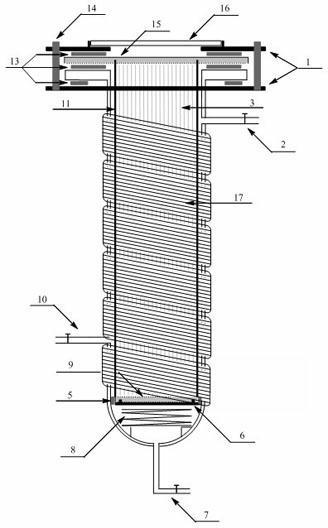

[0033] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

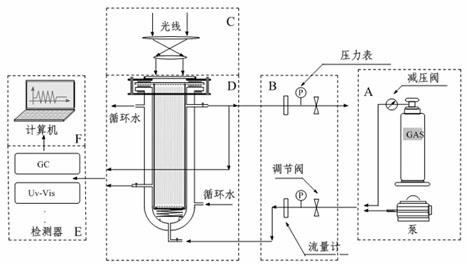

[0034] refer to figure 1 , taking the water circulation type as an example, the electric heating type is similar. Efficient TiO of the present invention 2 The photocatalytic microreactor and the photocatalytic degradation system of organic matter (such as 4-nitrophenol) in aqueous solution are mainly composed of gas supply system A, regulation system B, light source system C, reaction system D, detection system E and data processing system F , whose core is the reaction system D, where,

[0035] Gas supply system A includes gas cylinders (such as CO 2 , O 2 etc.) and pressure reducing valve. If the reaction only needs to blow in air, the air supply system only needs an air pump of appropriate power.

[0036] Regulating system B includes rotameters, barometers and gas regulating valves on the inlet and outlet pipeli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com