Novel concrete gravel-sand separation device

A technology for sand and gravel separation and concrete, which is applied in the direction of solid separation, wet separation, chemical instruments and methods, etc. It can solve the problems of high mud and water content in sand and gravel, inability to completely separate sand and stone, and affecting the quality of concrete. , to achieve the effect of low moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings. All similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

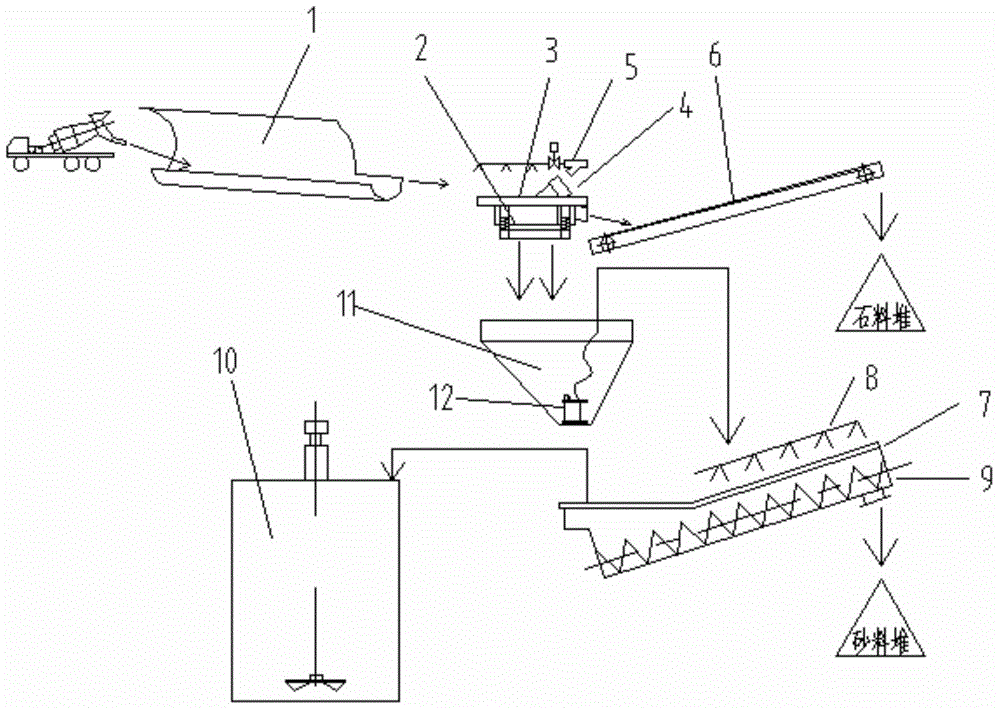

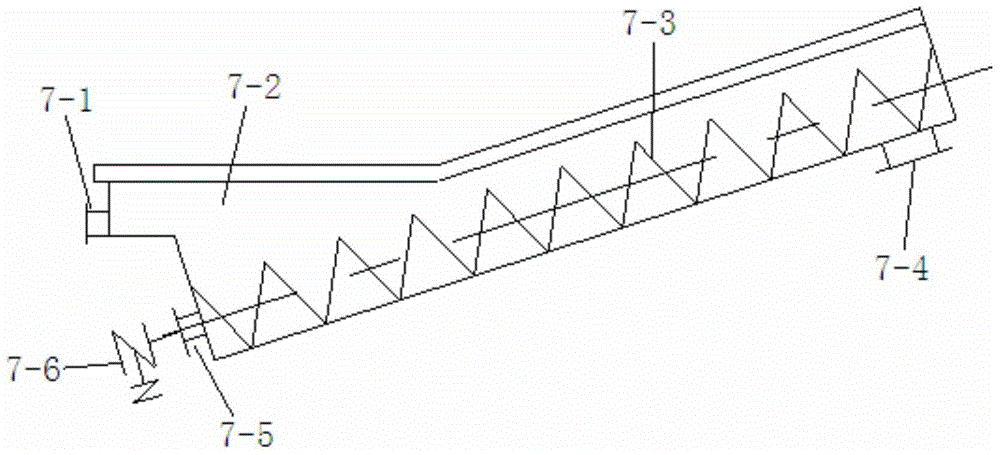

[0015] see figure 1 As shown, the present invention includes a car washing tank 1, a vibrating screen 3, a spiral sand separator 7, a mortar tank 11, a water pump 9, a stirring tank 10, a belt conveyor 6, a high-pressure washing part 5, and a washing part 8; it is characterized in that: a car washing tank 1 is connected to the vibrating screen 3, the remaining concrete of the mixer truck is discharged to the car washing tank 1, and flows to the vibrating screen 3 through the car washing tank 1, and the vibrating screen 3 is located directly above the mortar tank 11, and the water pump 9 is placed in the mortar tank 11, The outlet of the water pump 9 is connected to the spiral sand separator 7, and the outlet of the spiral sand separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com