Method and equipment for removing scale on metal wires or metal bars by grinding material water jet

An abrasive water jet, metal wire technology, applied in metal processing equipment, abrasive jet machine tools, abrasives, etc., can solve the problems of high failure rate, easy wear of high-pressure pumps, poor descaling effect, etc., to reduce labor intensity, Fast cleaning speed and good descaling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The concrete way of the inventive method is:

[0015] 1) Prepare abrasives, sand and water are prepared at a ratio of 30-50%;

[0016] 2) Pump the prepared abrasive through the mortar pump into the device that can divide the flow and then enter the cavity that can be sprayed; at the same time, the water is pressurized by the high-pressure pump to become high-pressure water and sent into the cavity, using high-pressure water as the power The impact abrasive is sprayed outward to descale metal wire or rod.

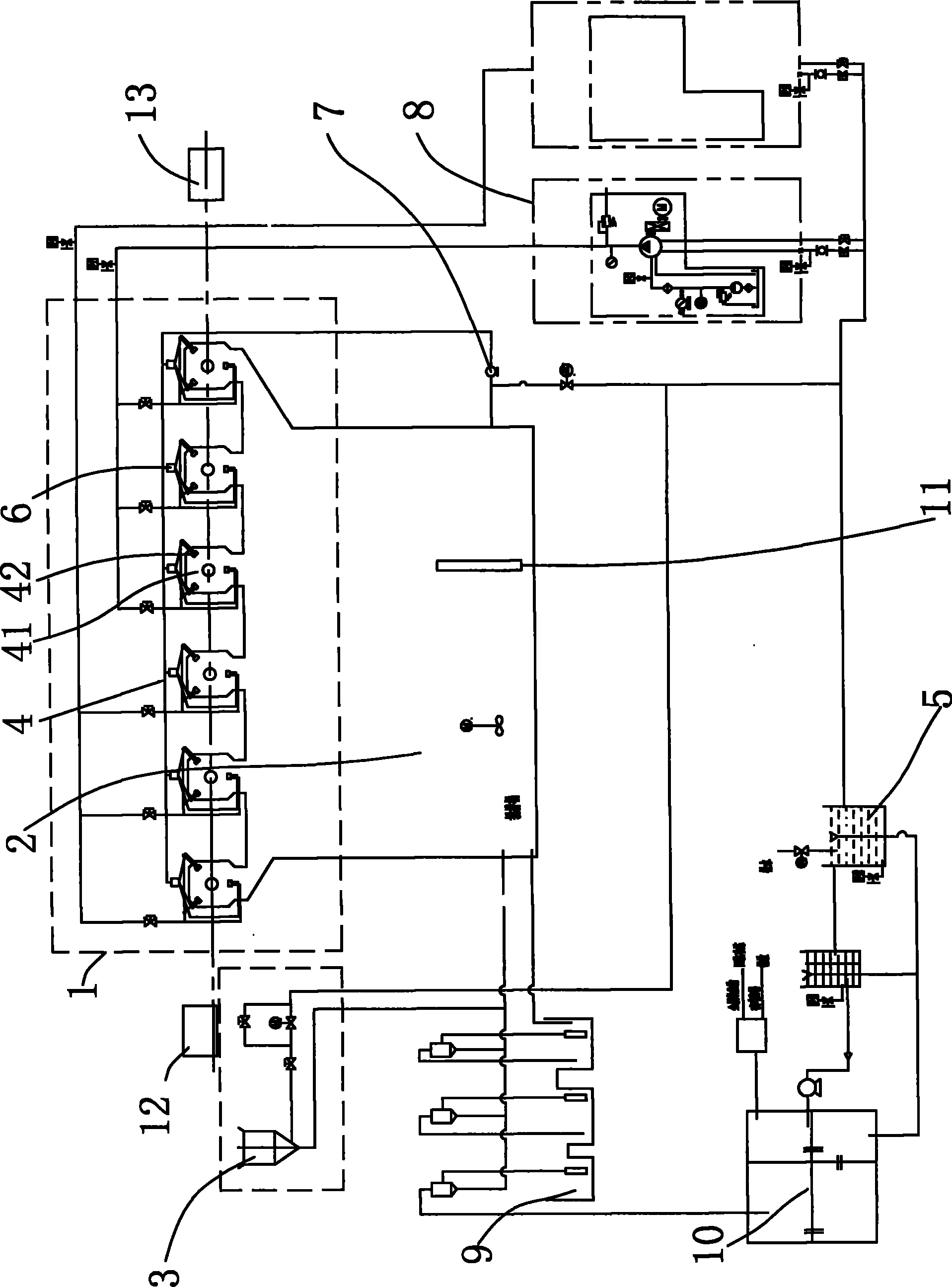

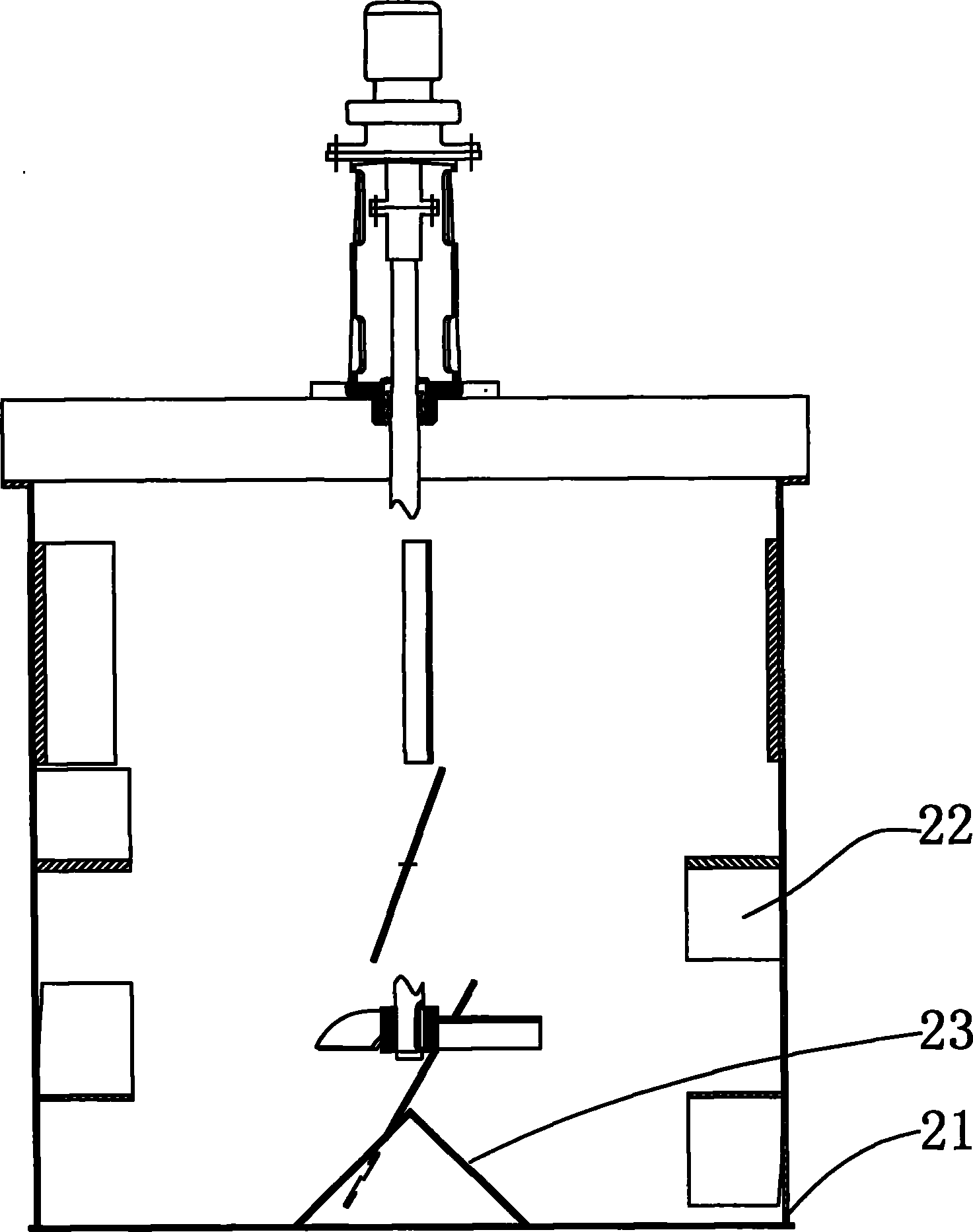

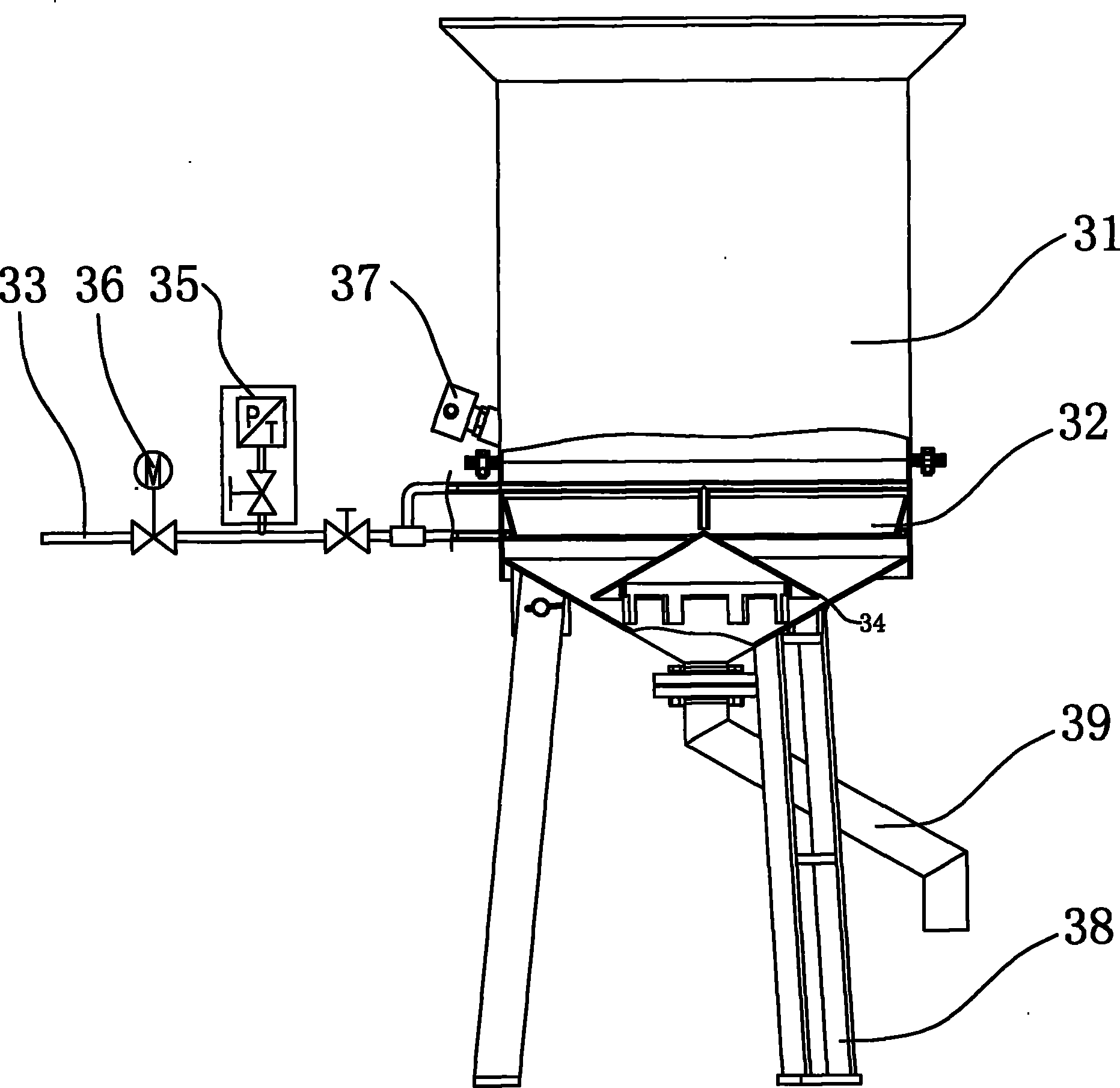

[0017] The special descaling equipment that the present invention provides for above-mentioned method is in figure 1 Reflected in , it includes a mixing tank 2 located under the descaling tank 1, an automatic fluidized sand adding device 3 for adding sand to the mixing tank, a spraying device 4, a water tank 5, and a sand separator 6 located in the descaling tank , A mortar pump 7 for supplying abrasives to the sand separator, a high-pressure pump 8 for producing hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com