Method and device for peeling off film

A peeling device and film clip technology, applied in the directions of transportation and packaging, optics, instruments, etc., can solve the problems of long process length, cost, complicated peeling process, etc., and achieve the effect of good operation efficiency and low consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

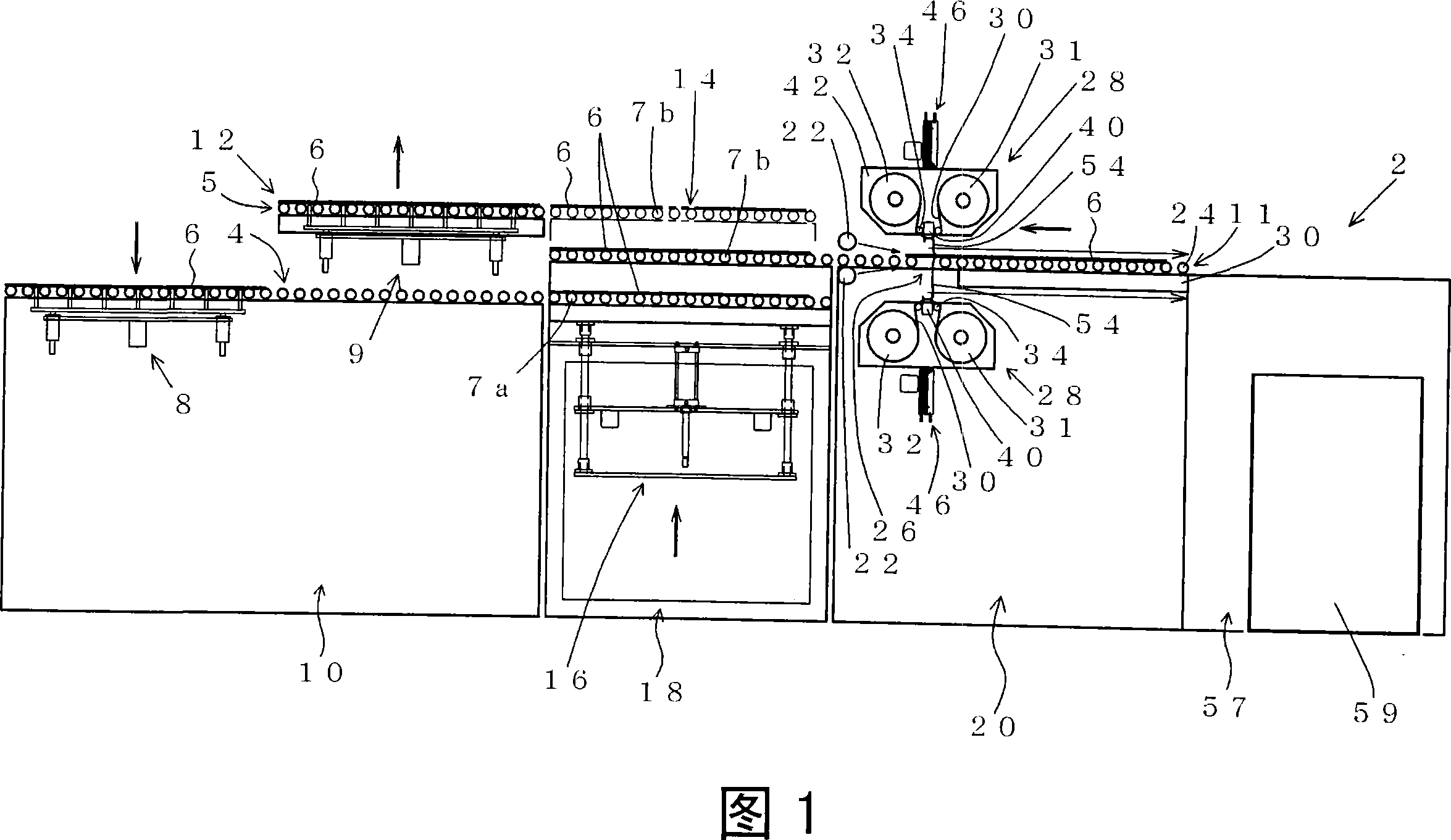

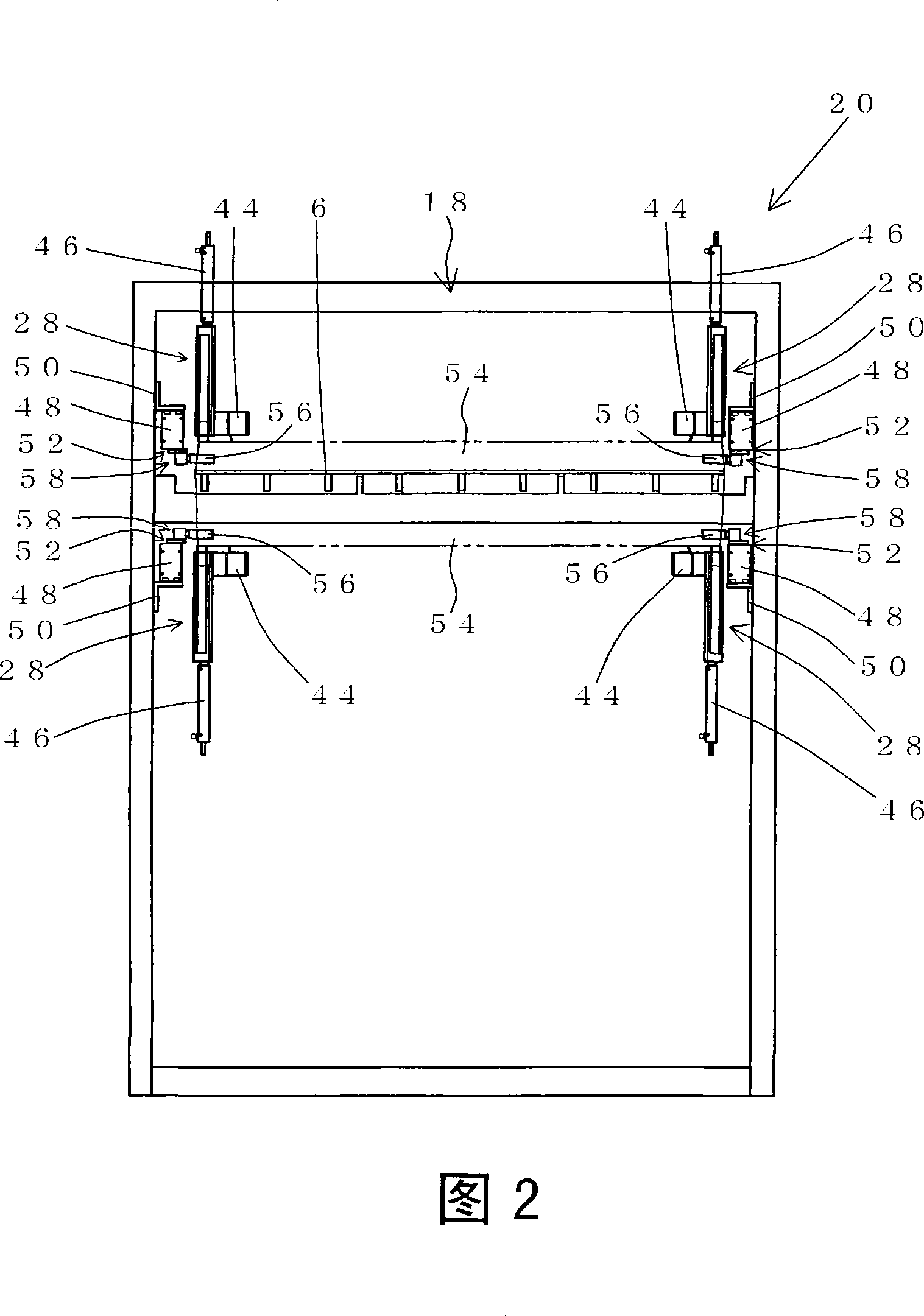

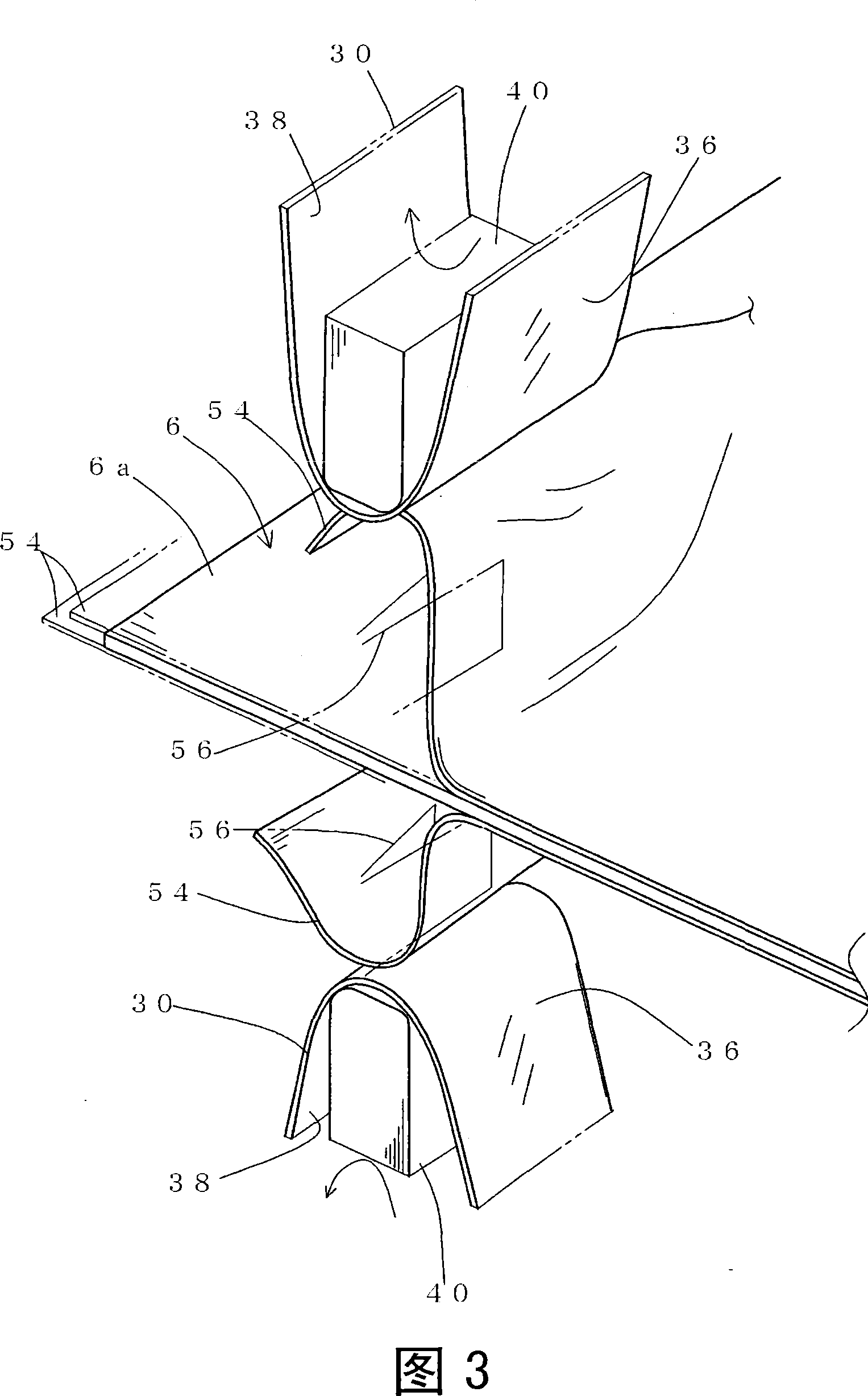

[0033] Hereinafter, the first embodiment of the film peeling method and apparatus of the present invention will be described with reference to FIGS. 1 to 4 . The film peeling apparatus of this embodiment is an apparatus which peels the protective film stuck in order to prevent the damage of the large glass substrate used for a liquid crystal display.

[0034] The structure of the film peeling apparatus 2 of this embodiment is demonstrated. The film peeling device 2 is provided with an input unit 10 provided with a roller conveyor 4 from the left end of FIG. A liftable substrate receiving device 8 for the substrate 6 . Above the input part 10, the take-out part 12 supported by the support structure which is not shown in figure, and which conveys the glass substrate 6 to the next process is provided. The take-out unit 12 includes a roller conveyor 5 , and includes a liftable substrate receiving device 9 that lifts the glass substrate 6 slightly from the roller conveyor 5 and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com