Path planning method of double-mechanical-arm collaborative assembly operation

A dual manipulator, path planning technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as low path quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings.

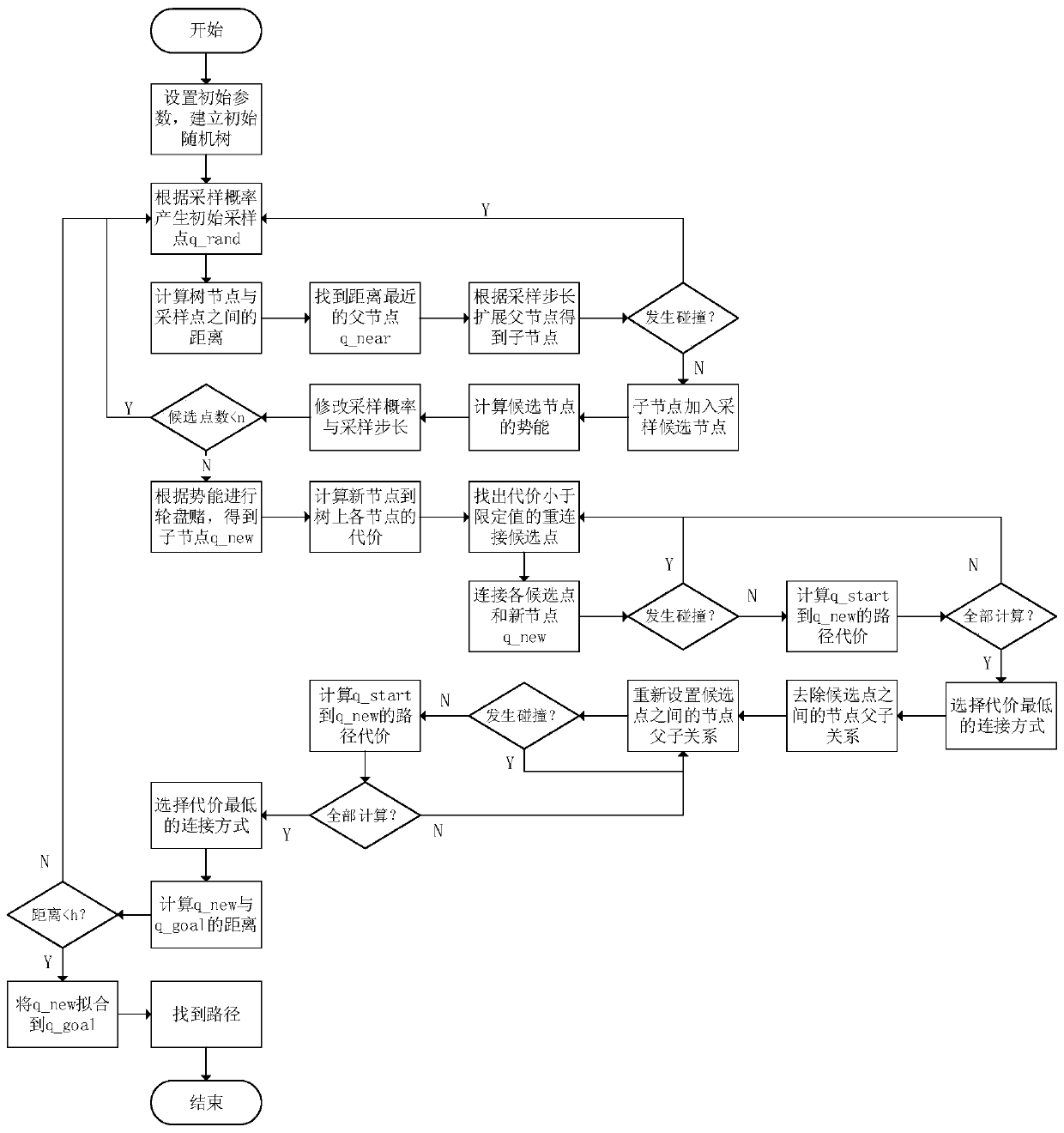

[0052] refer to figure 1 and figure 2 , a method for planning a dual robotic arm collaborative assembly operation, the method comprising the following steps:

[0053] Step 1: Establish the kinematics model and dynamics model of the dual-manipulator operation:

[0054]

[0055]

[0056]

[0057]

[0058]

[0059]

[0060] In the formula: Q is the joint position, is the coordinates of the i-th joint of the manipulator m in the basic coordinate system, is the coordinates of the i-th joint of the manipulator m in the base coordinate system of the manipulator m, P m is the transformation matrix from the base coordinate system of the manipulator m to the base coordinate system, R i is the pose matrix of joint i, T Hi is the transformation matrix from joint i to base coordinates, A i is the coordinate system conversion matrix of joint i and joint i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com