Energy-consuming steel rod replaceable beam-column joint node and construction method thereof

A beam-column connection and steel bar technology, which is applied to building components, earthquake resistance, building types, etc., can solve the problems of complex construction, poor structural floor integrity, and difficulty in replacing the embedded parts of the connection, so as to achieve a simple connection method and good waterproof performance. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

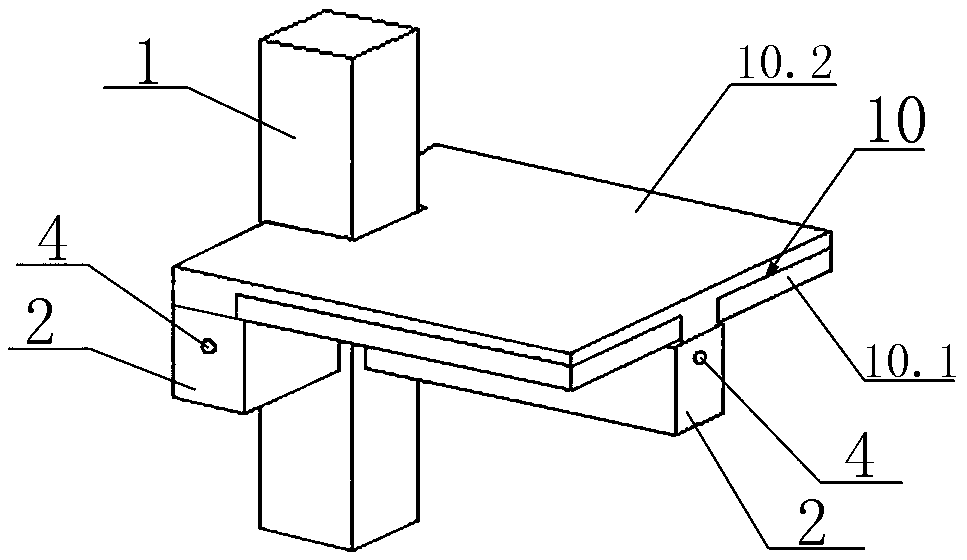

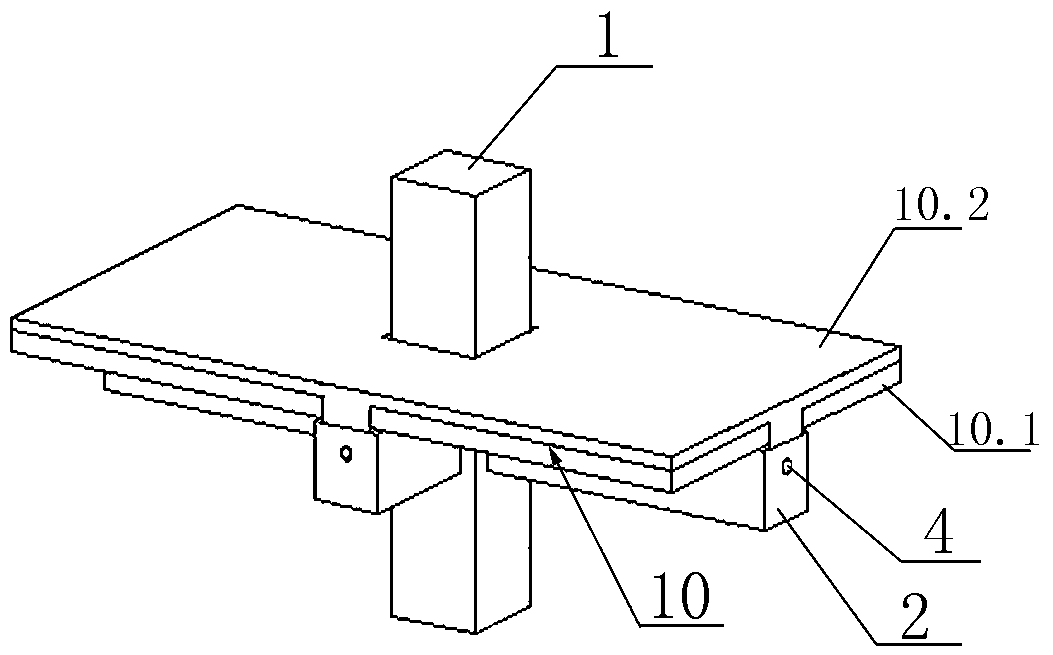

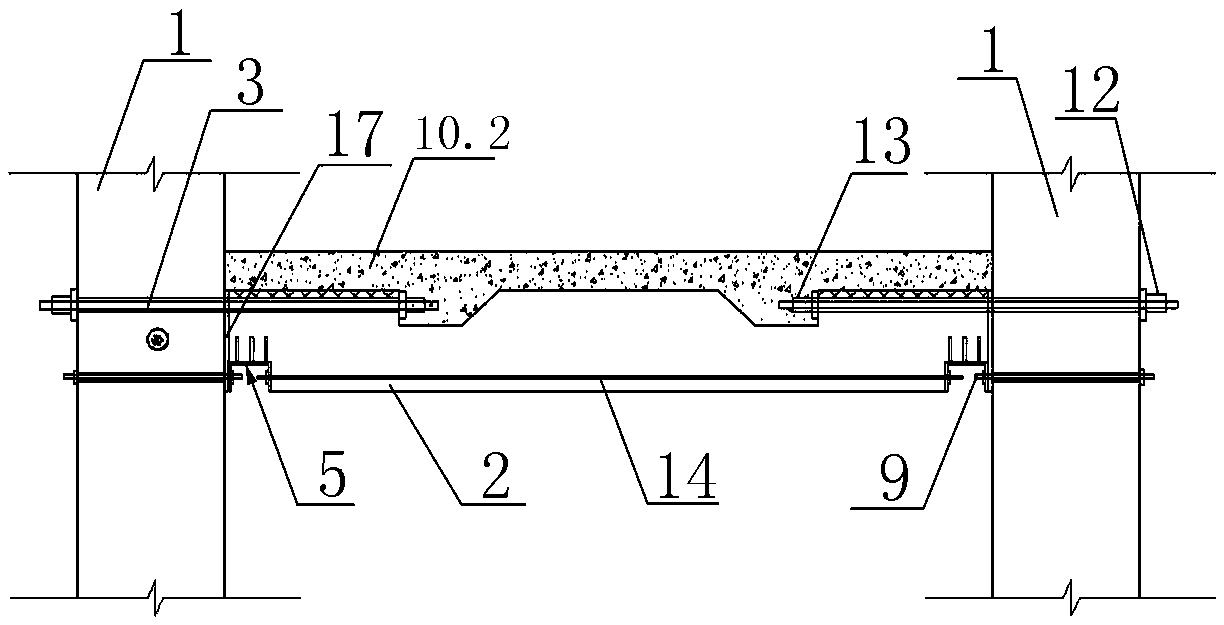

[0042] Such as Figure 1-10As shown, the beam-to-column connection node with replaceable energy-dissipating steel rods includes frame columns 1, prefabricated beams 2, prestressed tendons 3 and laminated floor slabs 10; the laminated floor slabs 10 include prefabricated slabs 10.1 and existing Pouring the composite layer 10.2; the prefabricated beam 2 is provided with a prestressed tendon tunnel 4; the frame column 1 is provided with a reinforcement tunnel 6 at a position corresponding to the prestressed tendon tunnel 4; the prestressed tendons 3 are pierced Provided in the prestressed tendon channel 4 and the reinforced channel 6, the prefabricated beam 2 and the frame column 1 are crimped and connected; a bonding material 17 is provided in the joint between the prefabricated beam 2 and the frame column 1; the prefabricated The bottom of the beam 2, near the two ends, is provided with a connection assembly 5; the connection assembly 5 includes a rectangular box 5.1 surrounded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com