Jaw crusher

A jaw crusher and clamping mechanism technology, applied in grain processing and other directions, can solve the problems of taking a long time, covering a large area, and increasing the price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

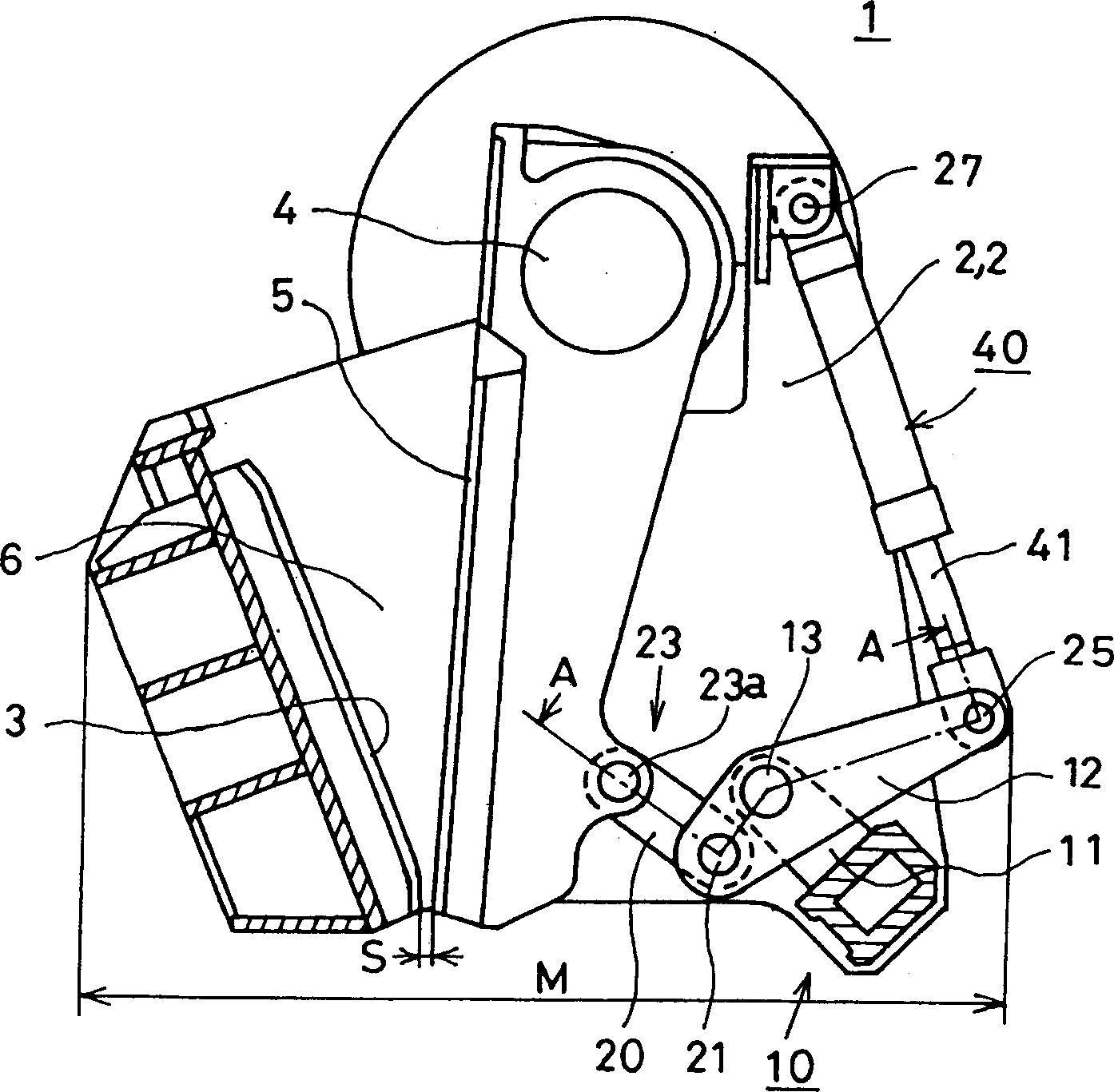

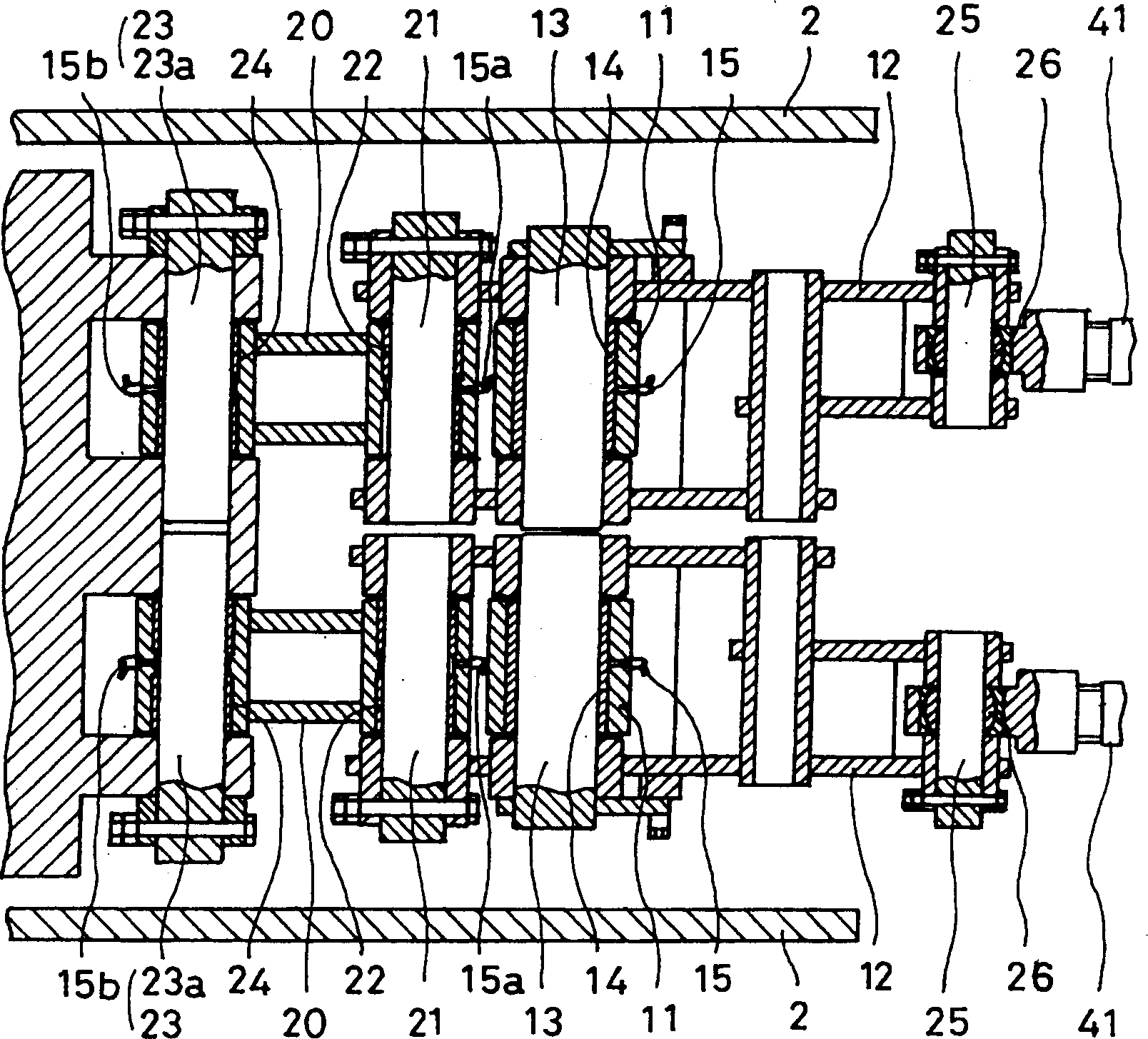

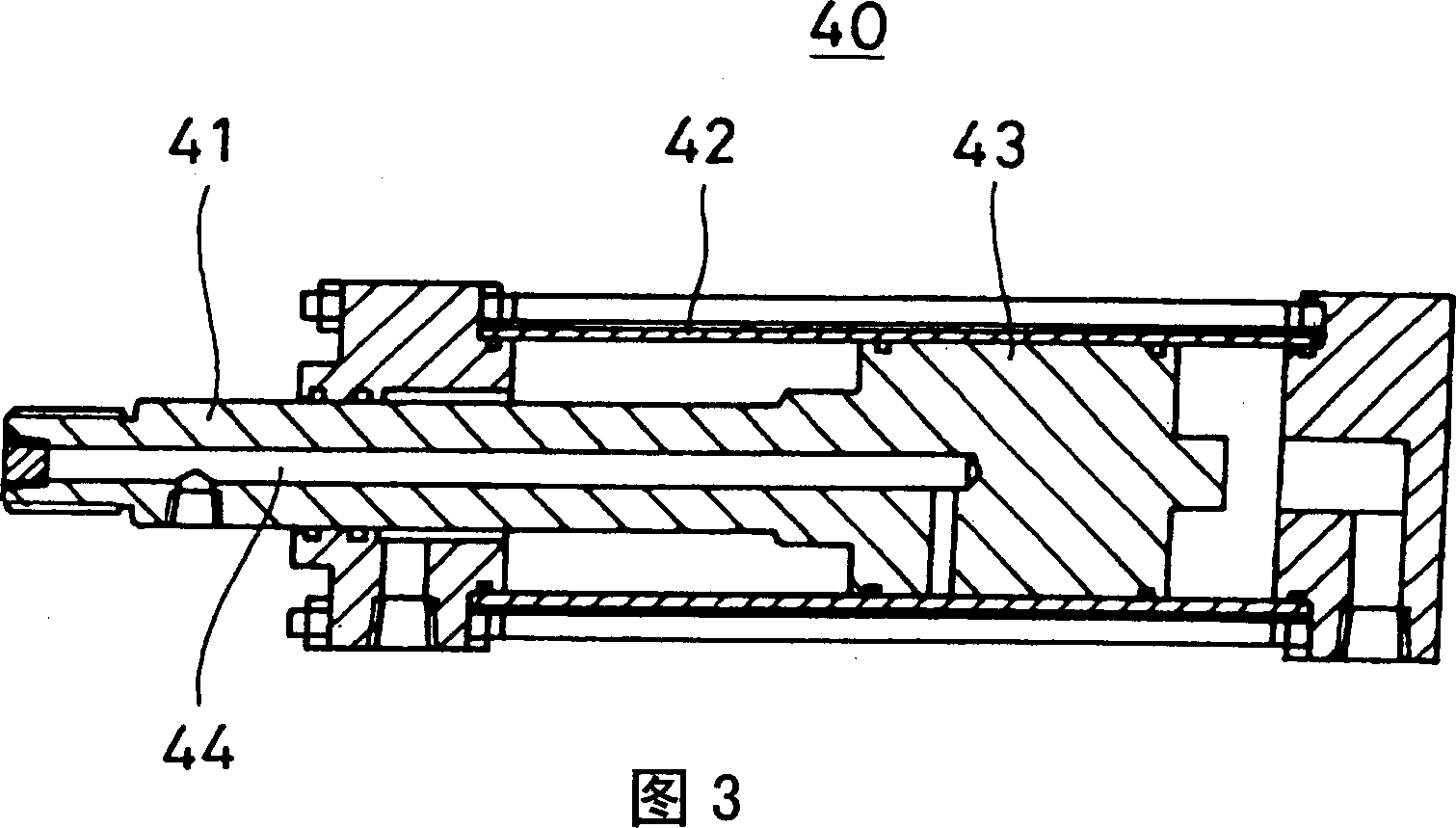

[0036] Preferred embodiments of the jaw crusher of the present invention will be described in detail below with reference to the accompanying drawings.

[0037] First, based on Figure 1 to Figure 6 The first embodiment will be described.

[0038] figure 1 It is a partial side sectional view showing an example of the jaw crusher 1 . exist figure 1 Among them, a fixed tooth 3 is installed between a pair of left and right fixed cones 2, 2, and at a position facing the fixed teeth 3, the movable tooth 5 swings and hangs freely on the eccentric drive shaft 4 set on the fixed cones 2, 2 Above, a crushing chamber 6 is formed between the fixed teeth 3 and the movable teeth 5 . On the back side of the movable tooth 5 between the fixed cones 2 and 2, a movable tooth bearing portion 10 forming a link mechanism is provided. That is, on the bracket 11 fixedly installed on the fixed cones 2 , 2 , the intermediate portion in the longitudinal direction of the lever 12 is swingably att...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com