Multifunctional ship type farming machinery

A multi-functional, tillage equipment technology, applied in the field of agricultural machinery, can solve the problems of disability, low production efficiency, difficulty in returning straw to the field, etc., and achieve the effects of lower power consumption, reduced untended tillage area, and optimal operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

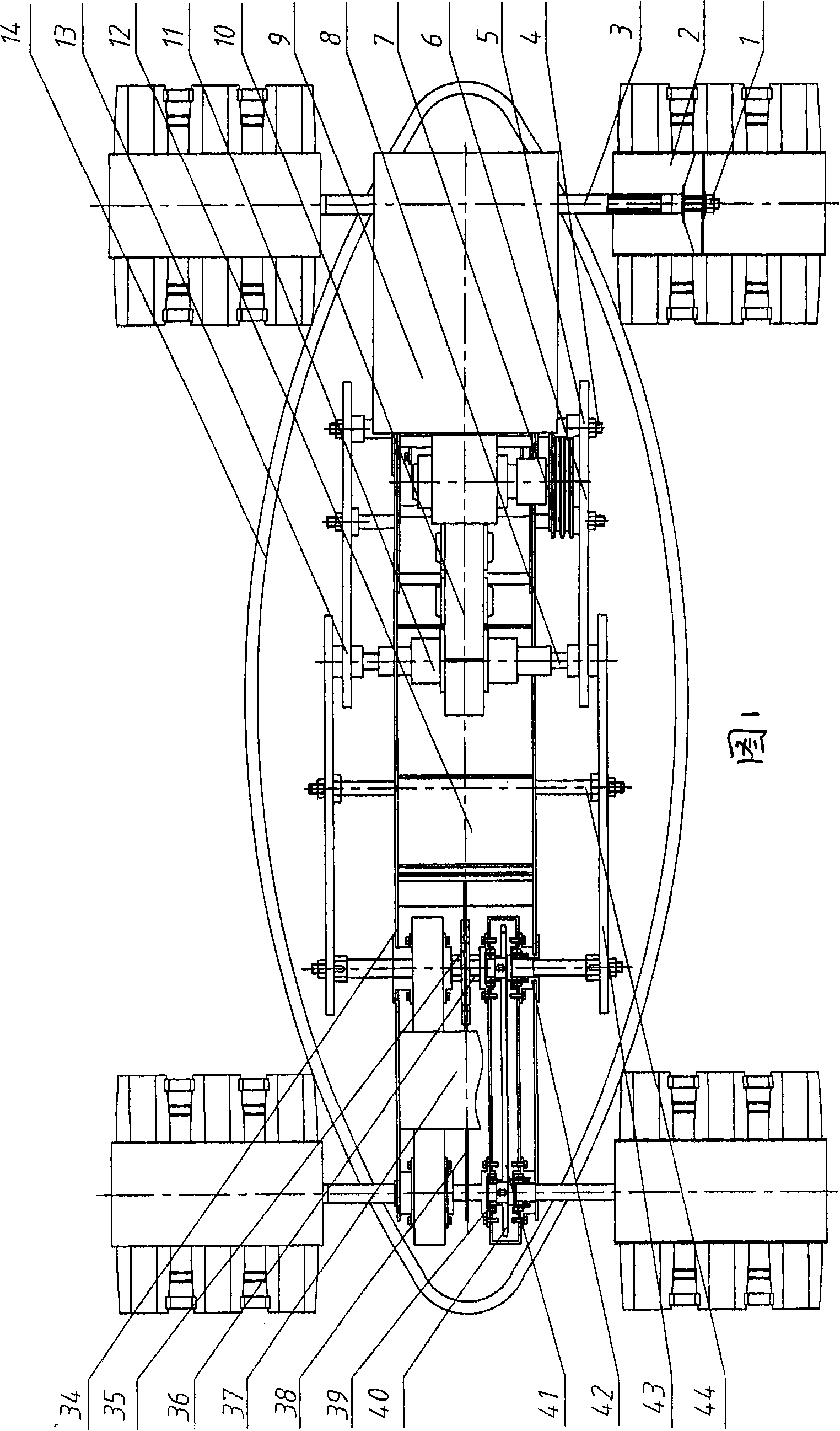

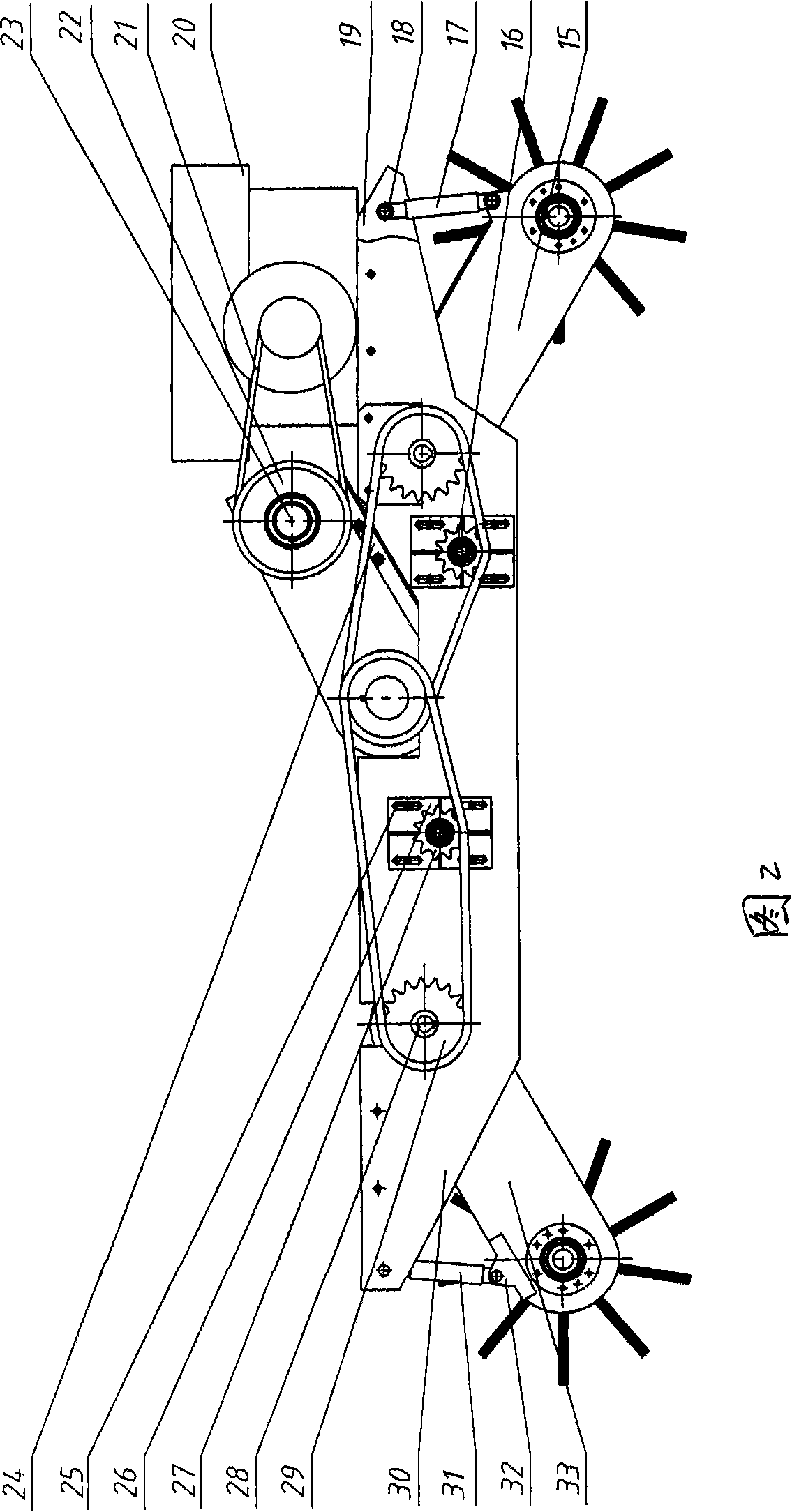

[0010] Referring to Fig. 1, 2, the present invention comprises cattail rolling fastening nut 1, catkin rolling 2, catkin roller shaft 3, rear transfer case input shaft 4, rear transfer case input sprocket 5, chain 6, gearbox clutch 7, Gearbox output shaft 8, frame rear reinforcement plate 9, gearbox 10, gearbox output shaft bearing end cover 11, frame middle section reinforcement plate 12, gearbox double output sprocket 13, hull 14, rear transfer case 15. Rear tensioner 16, rear adjustment hydraulic cylinder 17, connecting pin 18, rear support plate 19, engine 20, belt 21, clutch pulley 22, gearbox input shaft 23, gearbox mounting plate 24, tensioner adjustment groove 25. Tensioner bottom plate 26, front tensioner 27, front transfer case input shaft 28, front transfer case input sprocket 29, frame 30, front adjustment hydraulic cylinder 31, transfer case lug 32, front splitter Transfer case 33, frame side frame 34, front transfer case intermediate mounting plate 35, transfer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com