Measurement control method for field installation of steel tube lattice pier

A technology of measurement control and on-site installation, which is applied in the direction of measuring devices, mechanical measuring devices, angle/taper measurement, etc., can solve the problems of low stakeout accuracy, low operation efficiency, and susceptibility to falling objects, and achieve practical and obvious operations. The effect of high efficiency and high stakeout accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

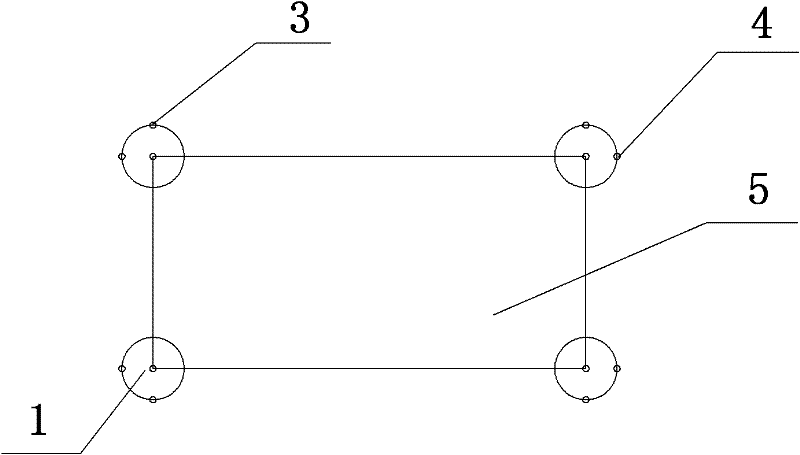

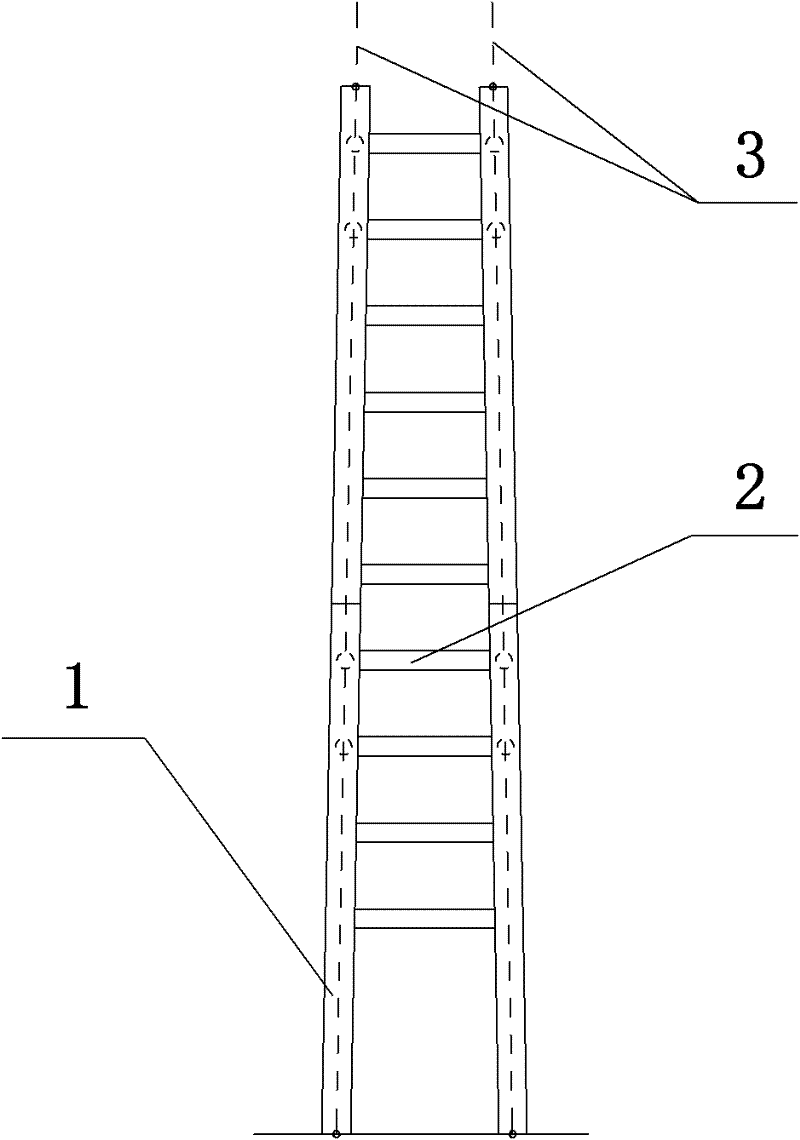

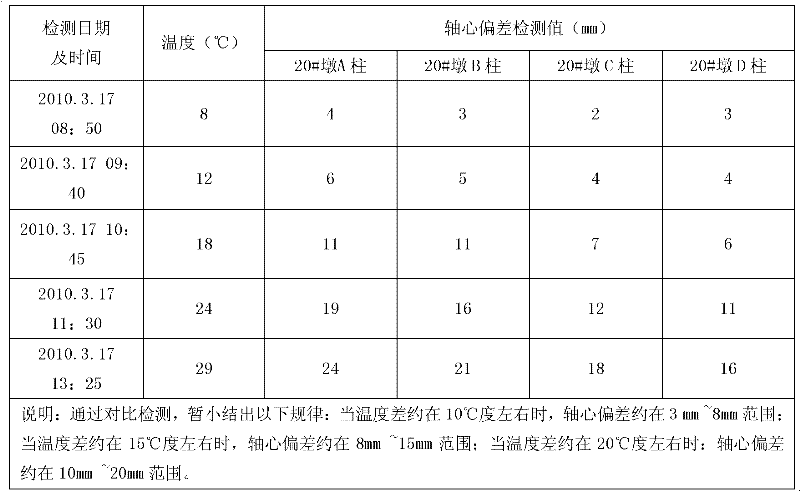

[0019] As an embodiment of the present invention, such as figure 1 with figure 2 As shown, a steel pipe lattice pier site installation measurement control method, the steel pipe lattice pier is composed of four upright steel pipes 1, a cross-link truss 5 is arranged every 12m along the pier height, and a connecting web pipe is arranged every 2m between the upright steel pipes 2. The construction of the steel pipe lattice pier is carried out in accordance with the pre-processed steel pipe segment unit and the cross-link truss 5 to the pier site for installation. The steel pipe segment unit is connected by two longitudinal A-frame steel pipes and cross braces composition.

[0020] The instrument model of the total station used in the present invention is Topcon Total Station-GTS7501, and its angle measurement accuracy is 1 second, and the distance measurement accuracy is ±1mm; the level instrument models are Beijing Bofei DSZ3-1 and Tianjin Oubo DS32H. Before the start of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com