The construction method and structure of the side excavation excavation of shield tunneling with the combination of origin shaft and hoisting shaft in underground excavation construction

A technology of originating shaft and shield tunneling, which is applied in the direction of earthwork drilling, mining equipment, tunnels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

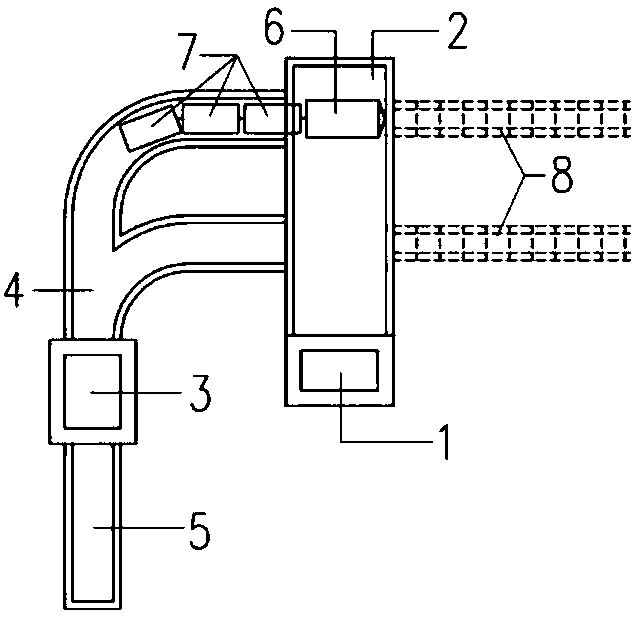

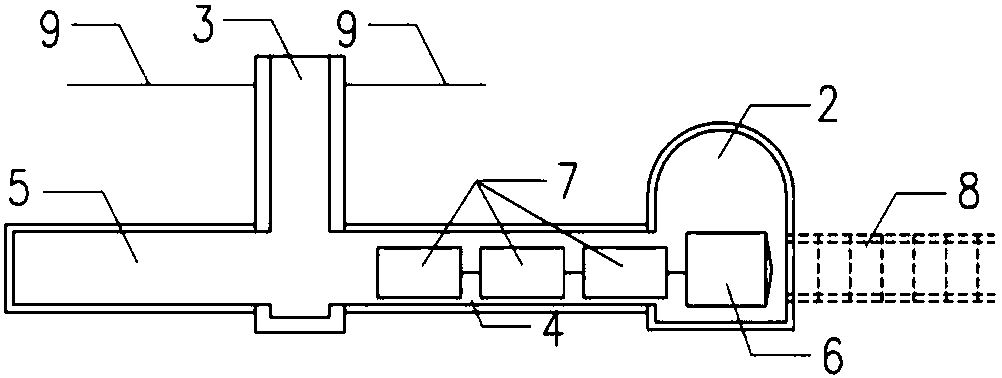

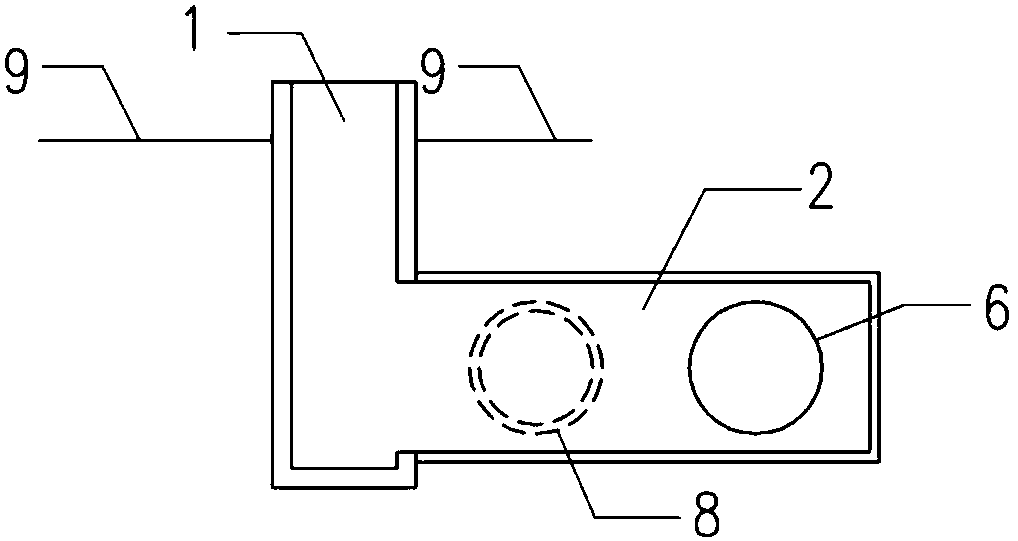

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] A shield excavation construction method combining the origination shaft and hoisting shaft of underground excavation construction. Through the construction method of underground excavation, shield tunneling can be set up in areas with small traffic volume, few pipelines, and no important buildings and structures. The launch shaft and the hoisting shaft are connected by a buried channel. A branch line is set in the channel connecting the hoisting shaft and the hoisting shaft, and the shield machine is hoisted in place through the hoisting shaft, and the shield machine is placed After being transported to areas with complex environments, the post-supporting equipment is hoisted into the connecting channel through the hoisting shaft, and the post-shield supporting equipment is placed in place through the connecting channel between the hoisting shaft and the starting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com