Interlock tube manufacturing method and manufacturing device therefor

A manufacturing method and a manufacturing device technology, which are applied in the field of the manufacture of interlocking pipes and their manufacturing devices, can solve the problems of springback, rotational loosening, and inability to maintain well, and are easy to achieve high accuracy, excellent work efficiency, and the realization of The effect of work efficiency and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

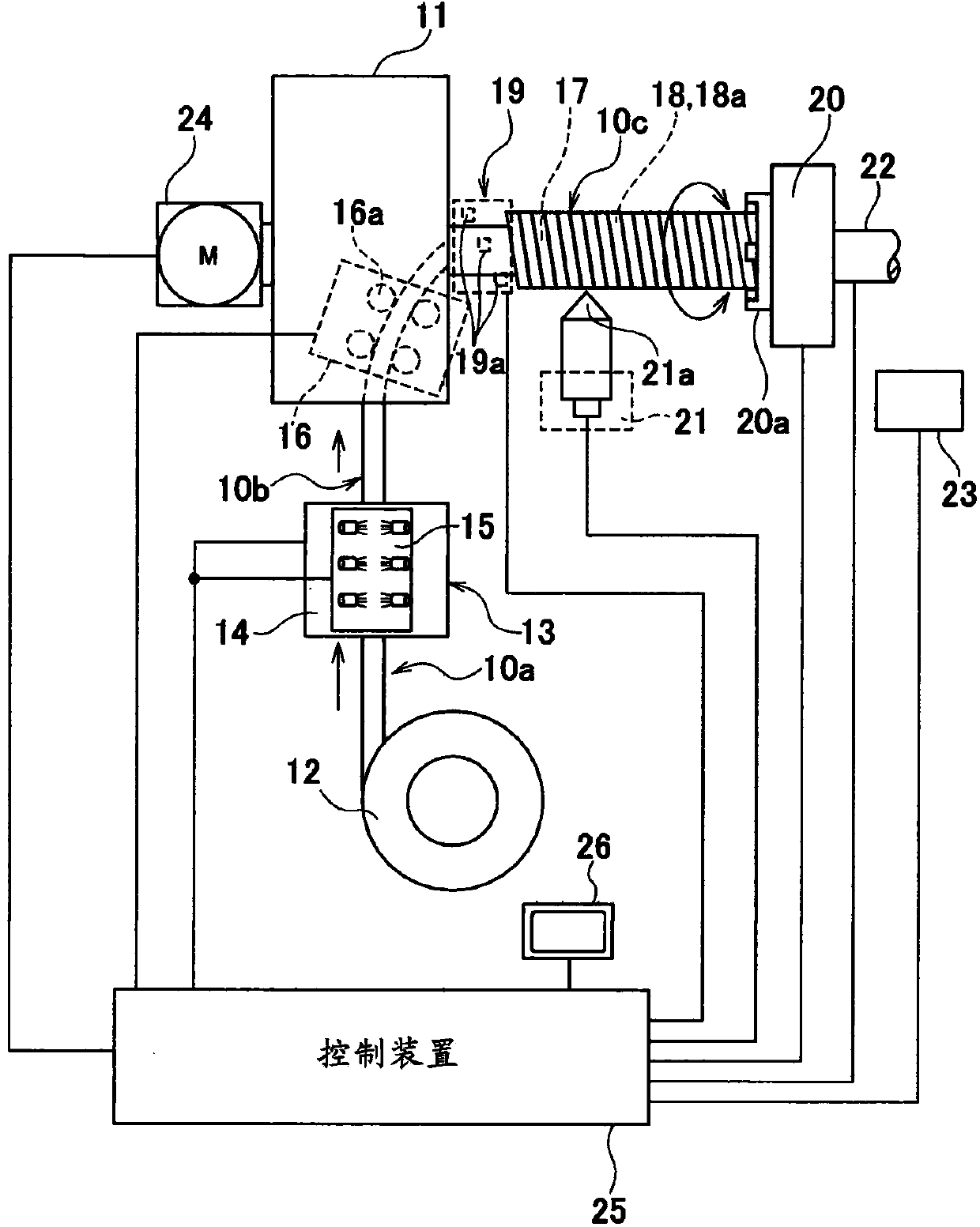

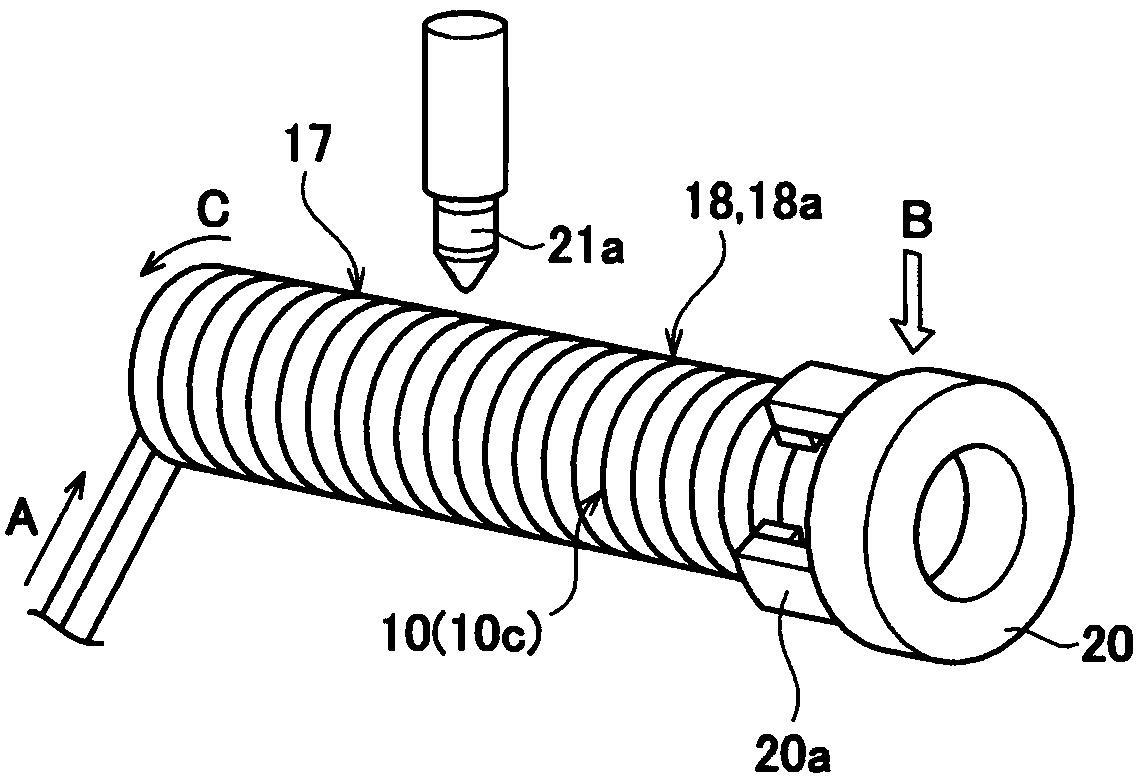

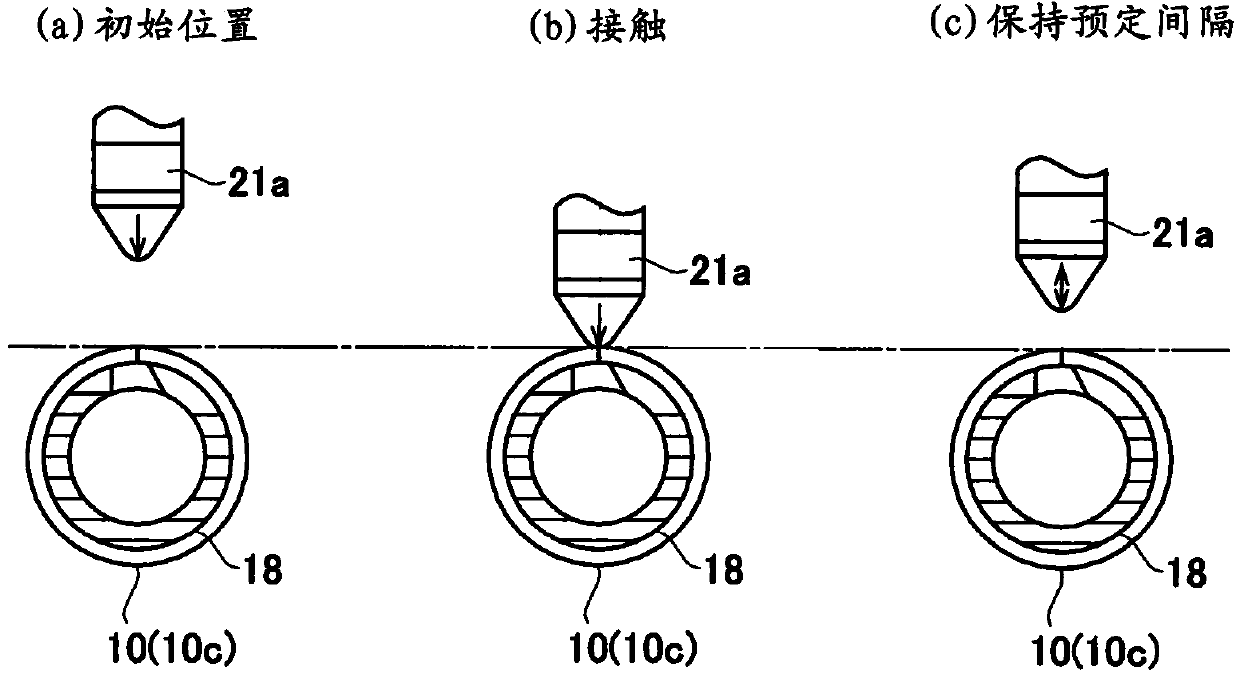

[0038] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 In order to obtain a semi-finished interlocking pipe 10 used as an exhaust pipe of an automobile, etc., a long flat metal strip 10a having a certain width is formed into a curved metal strip 10b, and at the same time, the forming It is a curved metal strip 10c wound in a spiral shape, and the metal strip 10c is cut into a predetermined length to obtain a semi-finished product of the interlocking pipe 10 . At the beginning, the flat metal strip 10a installed on the uncoiler 12 is pulled out from the uncoiler 12 and simultaneously sent to the pretreatment device 13 including the multi-stage roll forming device 14 and the oiling device 15 .

[0039] The multi-stage roll forming device 14 in the pretreatment device 13 is also as Figure 9 As shown, it is composed of a known multi-stage roll forming apparatus having substantially the same configuration as the conven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com