Bucket connection mechanism of small loading machine

A loader and bucket technology, which is applied in the field of small loader bucket connection, can solve the problems of small breakout force of the bucket, high hinge point between the bucket cylinder and the front frame, and affecting the operator's vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

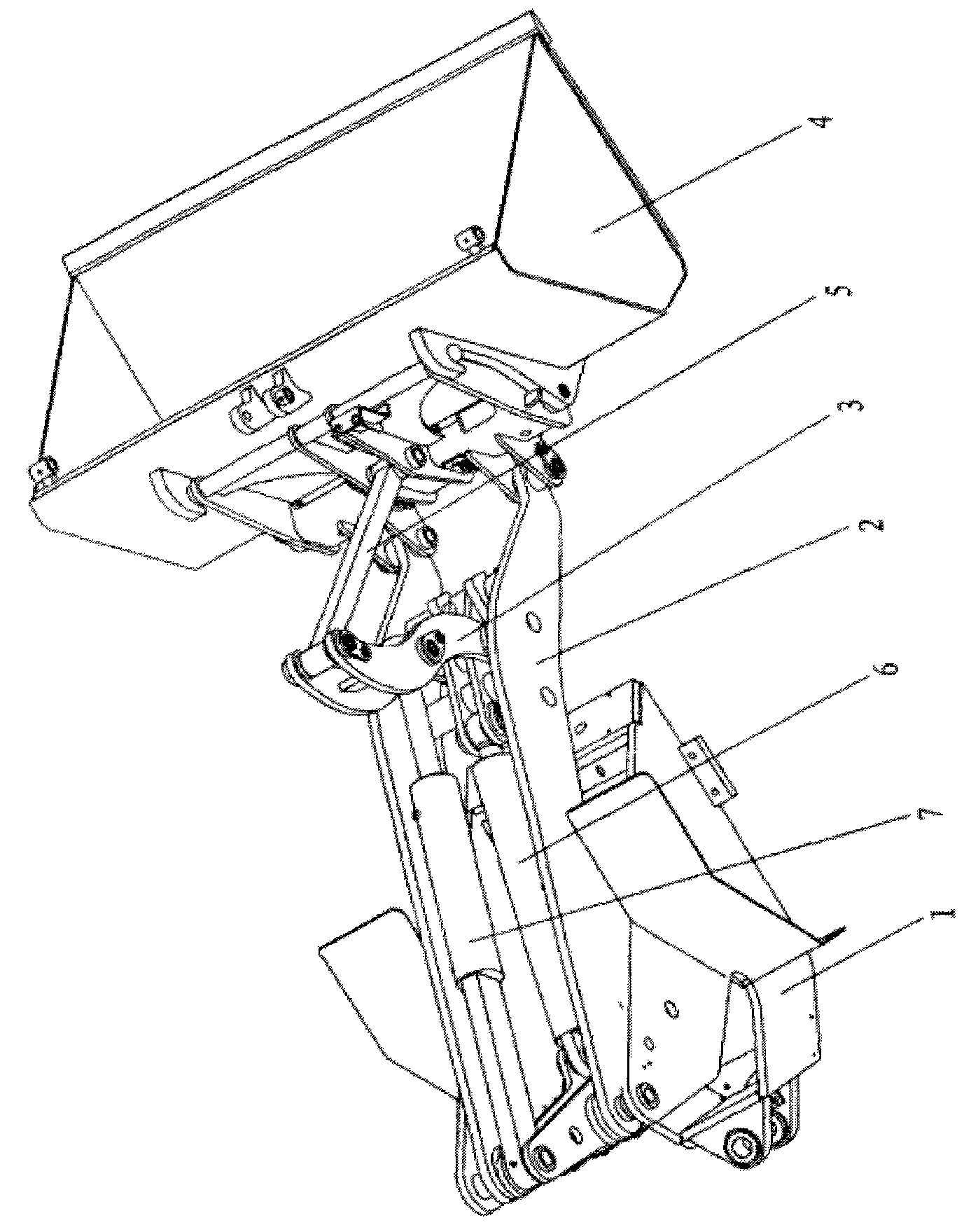

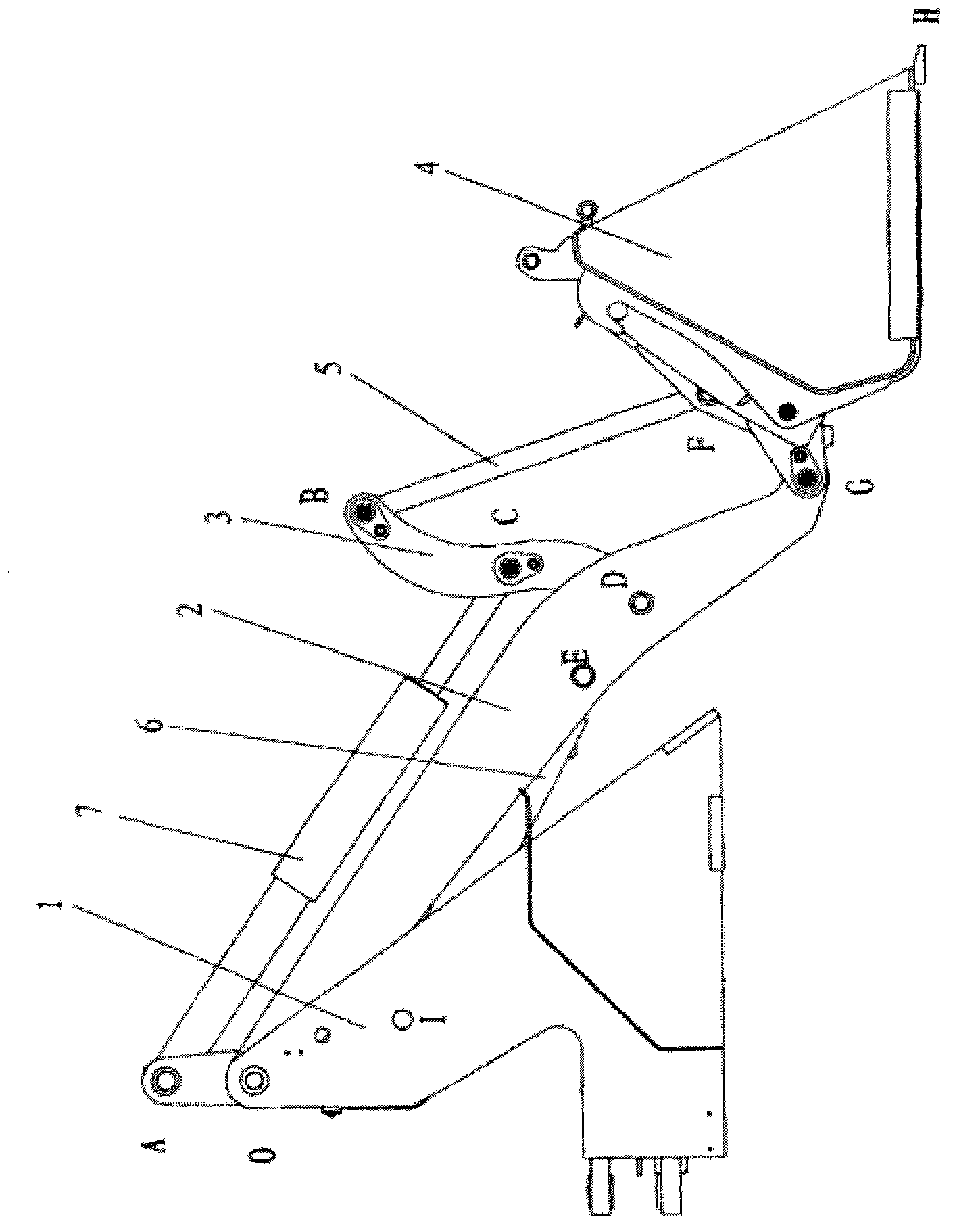

[0011] Such as figure 1 , 2 Shown is a kind of small loader bucket connection of the present invention, and it comprises front vehicle frame 1, boom 2, rocking arm 3, bucket 4, pull rod 5, boom cylinder 6 and bucket cylinder 7.

[0012] Each component of the present invention is connected into mechanism by the hinged form of bearing pin, and concrete connection mode is as follows:

[0013] One end of the boom 2 is hinged to the front frame 1, and the hinge point is O, and the other end is hinged to the bottom of the bucket 4, and the hinge point is G; the lower end of the rocker arm 3 is hinged to the boom 2 The front end is close to the predetermined position of the bucket 4 and constitutes a turning point, let the hinge point be D, the upper end of the rocker arm 3 is hinged with one end of the pull rod 5, let the hinge point be B, and the other end of the pull rod 5 is connected to the bucket 4. The middle part is hinged, so that the hinge point is F; one end of the boom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com