Loaders with booster cylinders

A loader and oil cylinder technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve problems such as the difficulty of increasing breakout force, improve bucket full rate, and facilitate layout , the effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

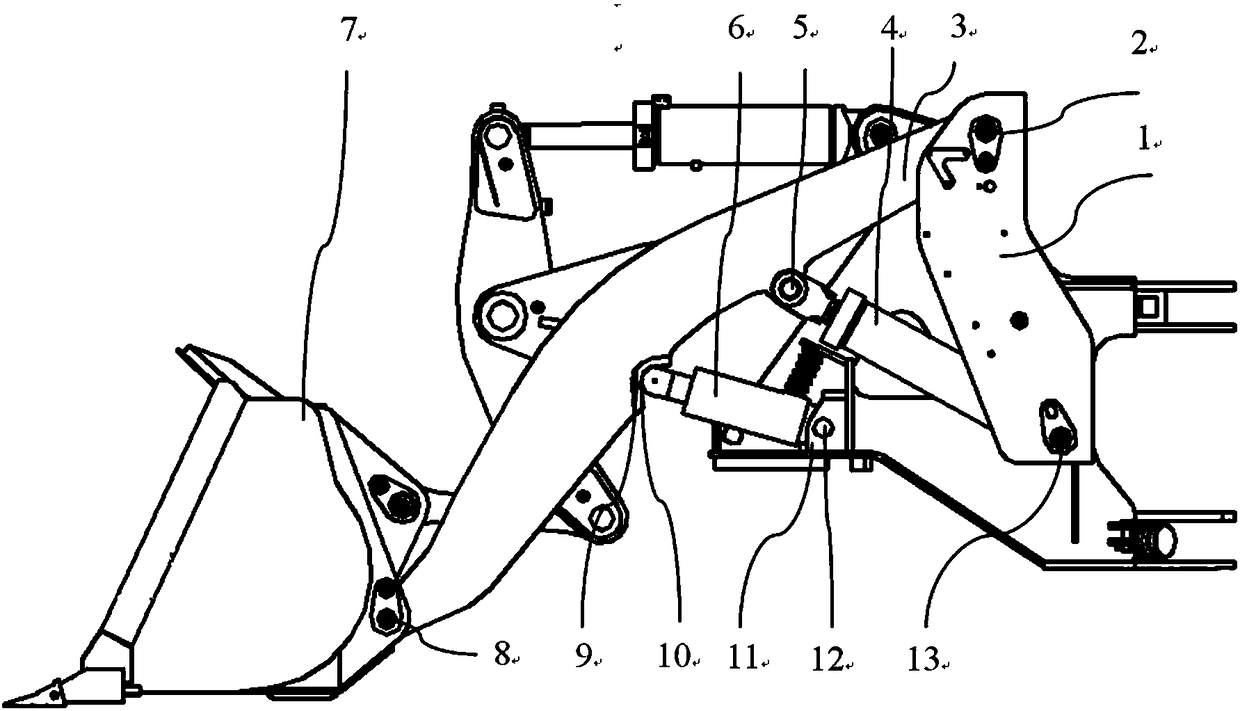

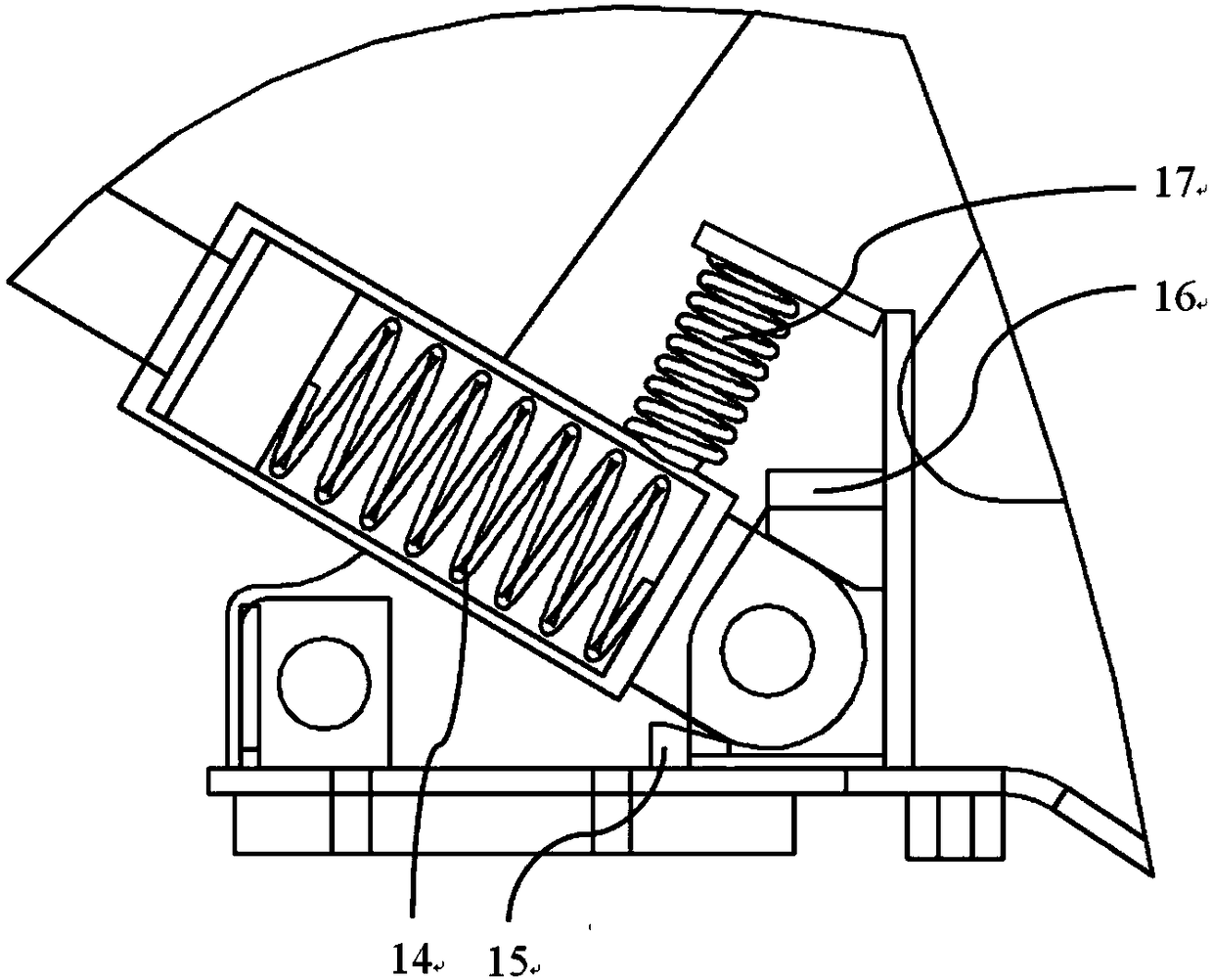

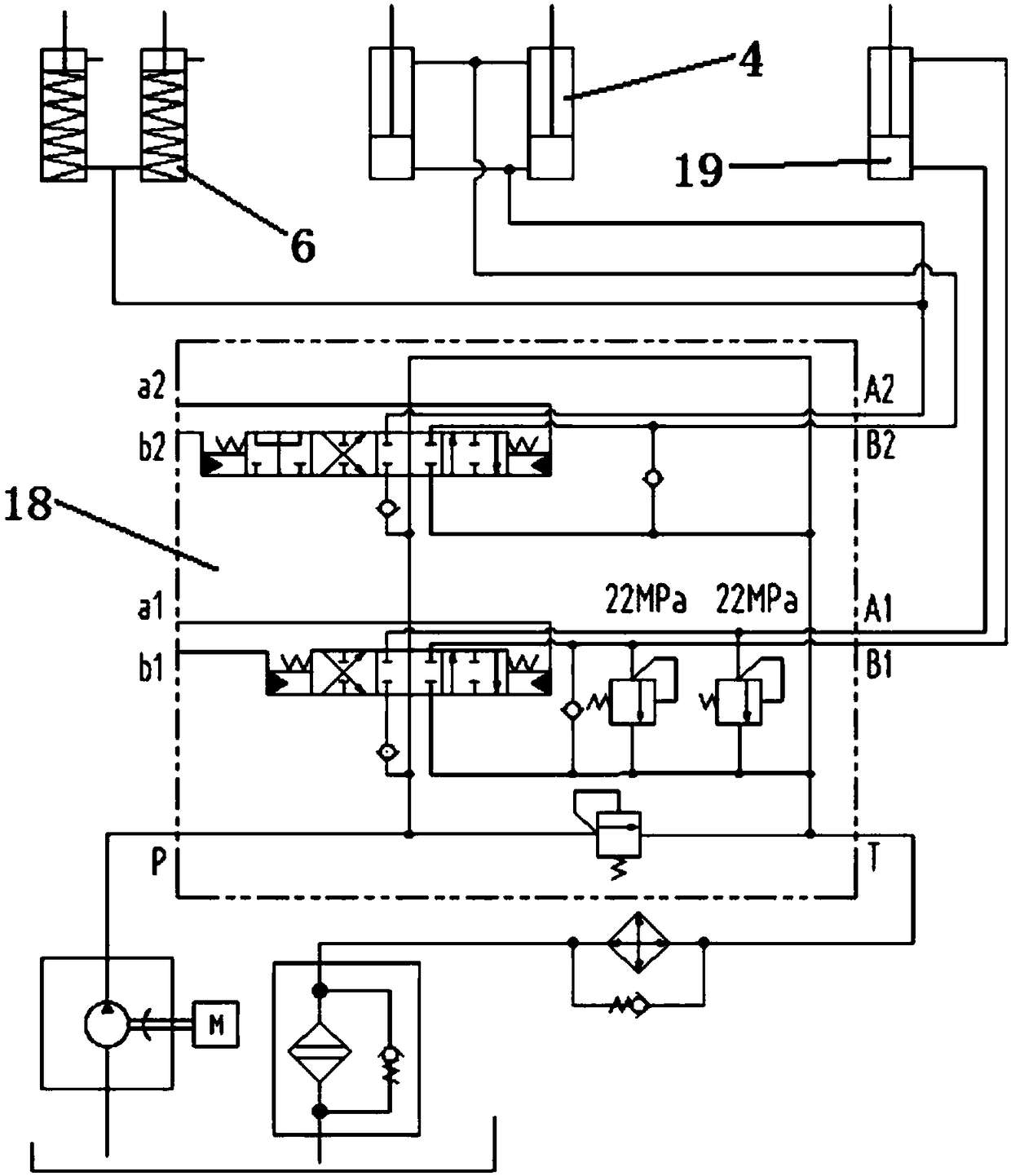

[0027] The specific implementation will be described below in conjunction with the accompanying drawings.

[0028] like figure 1 As shown, the loader in this embodiment includes a vehicle frame 1, a boom 3, a hydraulic system, and a booster cylinder 6. The rear end of the boom 3 is hinged to the frame 1 through the rear hinge shaft 2 of the boom, and the front end is articulated through the boom shaft 2. The front hinge shaft 8 is hinged to the bucket 7, and the two ends of the boom cylinder 4 in the hydraulic system are respectively hinged between the boom 3 and the vehicle frame 1, wherein the front end of the boom cylinder 4 is connected to the front hinge shaft 5 of the boom cylinder through the boom cylinder 4. The boom 3 is hinged, the rear end of the boom cylinder 4 is hinged with the vehicle frame 1 through the rear hinge shaft 13 of the boom cylinder, and the telescopic lifting boom 3 of the boom cylinder 4 rotates around the hinge point at the rear end of the boom. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com