Working mechanism for underground coal mine ultra-heavy shovel plate type shield hauler

A technology of support truck and working mechanism, which is applied in the direction of lifting device, etc., and can solve the problems that the shovel cannot be raised, the vehicle cannot be transported normally, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

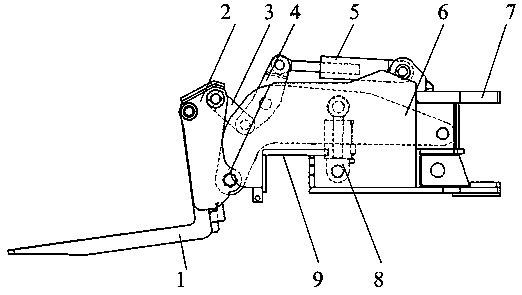

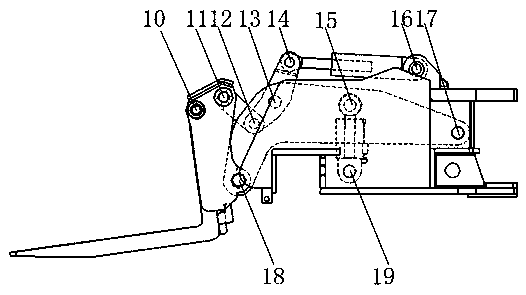

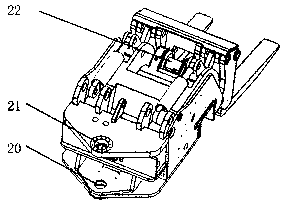

[0017] Such as figure 1 , 2 As shown, a working mechanism for an ultra-heavy-duty shovel-type support truck in a coal mine, a working mechanism for an ultra-heavy-duty shovel-type support truck in a coal mine, including a fork 1, a fork seat 2, and a connecting rod 3 , rocker arm 4, tilting cylinder group 5, boom 6, front frame 7 and lifting cylinder group 8, fork 1 and fork seat 2 are fixed by hinge pin group I10, and are limited by limit blocks; The connecting rod 3 is a group, one end of the connecting rod 3 is connected with the fork seat through the hinge pin group II11, the other end of the connecting rod 3 is connected with one end of the rocker arm 4 through the hinge pin group III12, and the other end of the rocker arm 4 is connected with the tipping pin group II11. The piston rod ears of the oil cylinder group 5 are connected through the hinge pin group V14, the middle part of the rocker arm 4 is connected with the big arm 6 through the hinge pin group IV13, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com