An automatic cutting device for the production of rod-shaped building materials

A technology for cutting devices and building materials, which is applied in the direction of shearing devices, shearing machine accessories, shearing machine equipment, etc., and can solve problems such as troublesome operation, fixed structure, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

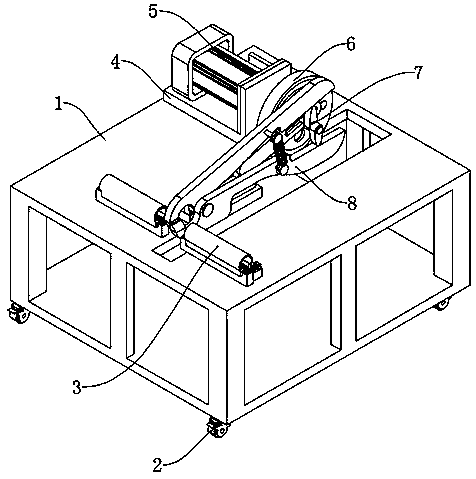

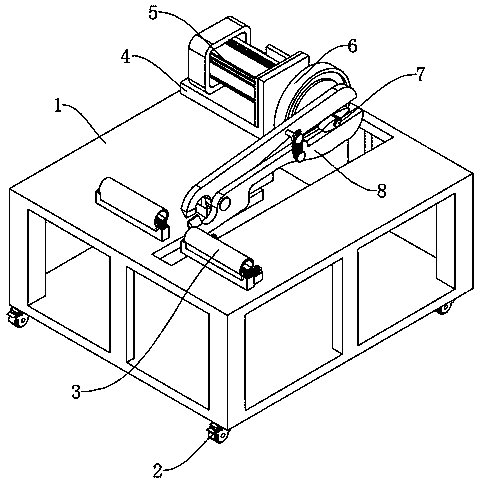

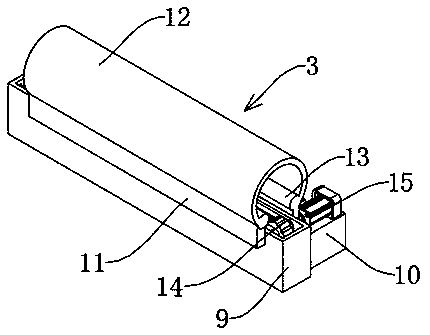

[0028] see Figure 1-4, an automatic cutting device for the production of rod-shaped building materials, including a mounting frame 1 and a roller 2, the roller 2 is fixedly connected to the four corners of the bottom surface of the mounting frame 1, a braking device is also fixedly connected to the roller 2, and the upper surface of the mounting frame 1 is provided with The raw material conveying device 3, the raw material conveying device 3 includes a raw material input end and a raw material output end, there is a gap between the raw material input end and the raw material output end, a movable opening is arranged under the gap, and the movable opening is arranged on the upper surface of the mounting frame 1, The upper surface of the mounting frame 1 is also fixedly connected with a first mounting base 4, the first mounting base 4 is fixedly connected with a servo motor 5, the output shaft of the servo motor 5 is fixedly connected with a turntable 6, and the turntable 6 is p...

Embodiment 2

[0032] see Figure 5 , based on Embodiment 1, the difference is that;

[0033] The second linkage mechanism 14 includes a raw material conveying roller 16, the side wall of the raw material conveying roller 16 is fixedly connected with a linkage gear 17, and the end of the linkage gear 17 away from the raw material conveying roller 16 is fixedly connected with a connecting shaft 18, which is close to the connecting shaft 18 of the drive motor 15 It is fixedly connected with the output shaft of the driving motor 15, and the connecting shaft 18 away from the driving motor 15 is rotationally connected with the inner side wall of the installation groove. The interlocking gear 17 is surrounded by an interlocking belt 19, and the inner wall of the interlocking belt 19 is provided with a gear groove. Groove matches with linkage gear 17.

[0034] The present invention is equipped with a raw material conveying device 3 on the device body. When in use, the manufacturing raw materials o...

Embodiment 3

[0036] refer to Figure 6-7 ; Based on Embodiment 1 or 2, the difference is that;

[0037] Cutting mechanism 8 comprises a first cut-off frame 29 and a second cut-off frame 30, the truncated end of the first cut-off frame 29 and the second cut-off frame 30 is provided with a cut-off edge, the junction of the first cut-off frame 29 and the second cut-off frame 30 A first connection shaft 31 is provided, and the first cut-off frame 29 is rotatably connected with the second cut-off frame 30 by the first connection shaft 31. The first cut-off frame 29 and the second cut-off frame 30 are also fixedly connected with a fixed rod 32, the fixed rod 32 is fixedly connected with spring 33.

[0038] The first linkage mechanism 7 includes a second connecting shaft 21, the second connecting shaft 21 is fixedly connected to the turntable 6, and the end of the second connecting shaft 21 away from the turntable 6 is also fixedly connected with a first arc-shaped adjustment block 22 and a seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com