Industrial wastewater rapidly-processing device used for reducing sewage discharge

A technology for industrial wastewater and treatment equipment, applied in the direction of sterilization/microdynamic water/sewage treatment, etc., which can solve the problems of reduced connection degree and service life of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

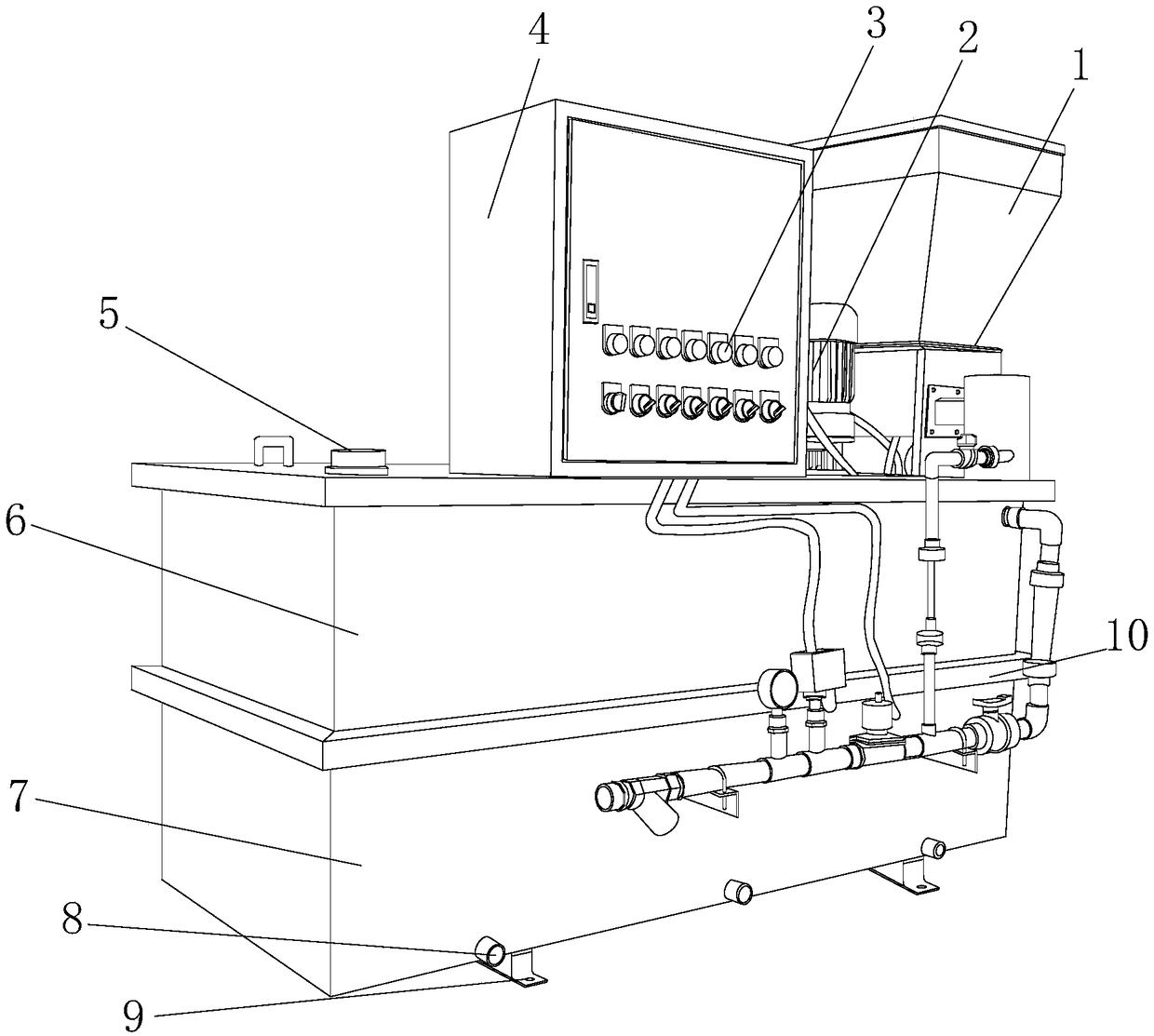

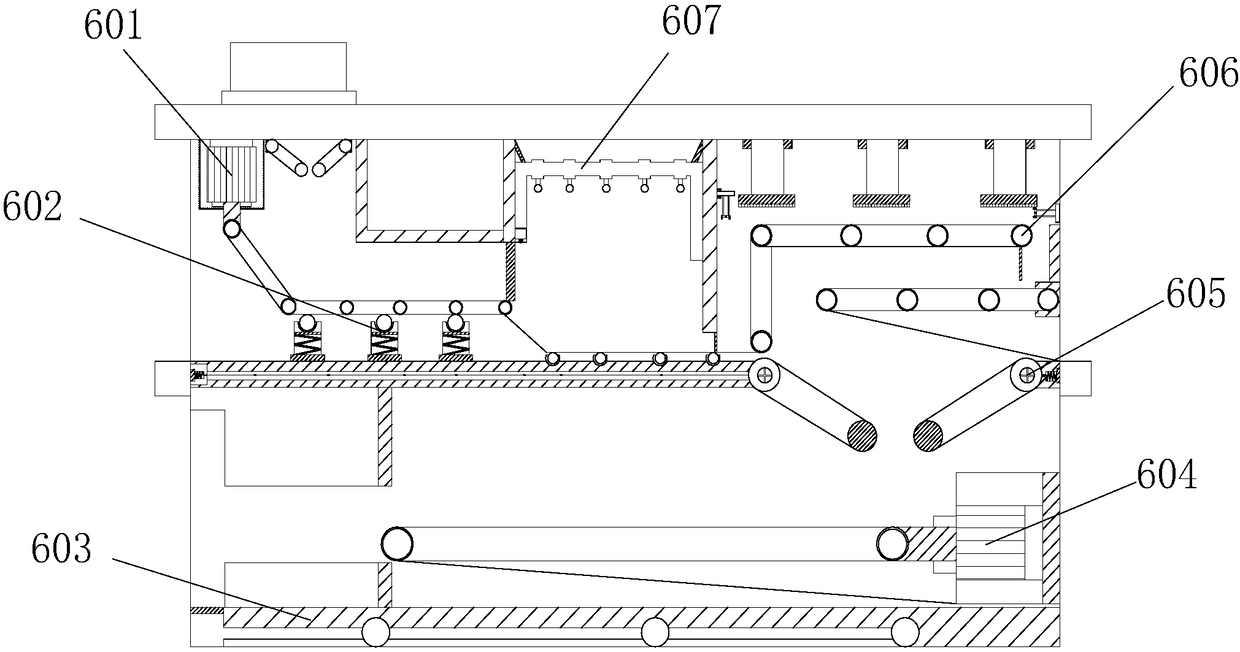

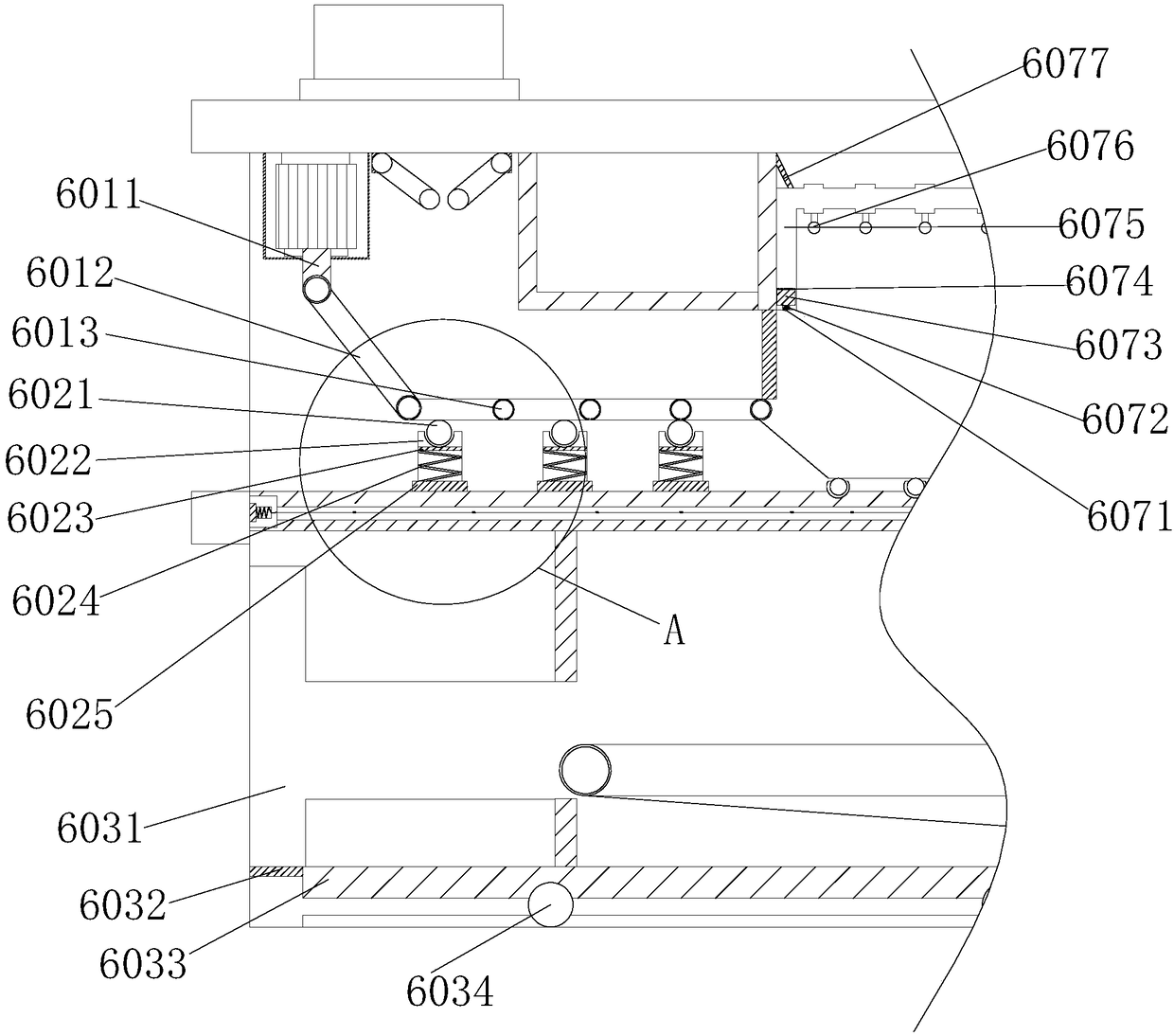

[0026] see Figure 1-Figure 6 , the present invention provides a rapid industrial wastewater treatment device for reducing sewage discharge, its mechanism includes a maintenance channel 1, a motor 2, a control button 3, an electric control box 4, a sewage water inlet 5, a purification box 6, and a clean water storage box Body 7, water outlet 8, support feet 9, partition 10, the maintenance channel 1 is welded on the top of the purification box 6 and its interior is connected to each other, the bottom of the motor 2 is installed on the top of the purification box 6, the control button 3. The internal signal terminal is electrically connected to the electric control box 4. The bottom of the electric control box 4 is horizontally fixed to the top of the purification box 6. The sewage water inlet 5 is installed at the leftmost end of the top of the purification box 6 and the insides are connected to each other. The purification box 6 and the clean water storage box 7 are an integr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com