Cutting ring assembly for rice mill

A technology of cutting ring and rice milling machine, applied in application, grain processing, grain pod removal, etc., can solve the problems of insufficient air, insufficient cooling of rice grains, and inability to completely remove rice bran, etc., so as to save costs and simplify the production of guide blades Excellent process and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Other objects, specific advantages, and novel features of the present invention will become clearer from the following detailed description and preferred embodiments associated with the accompanying drawings.

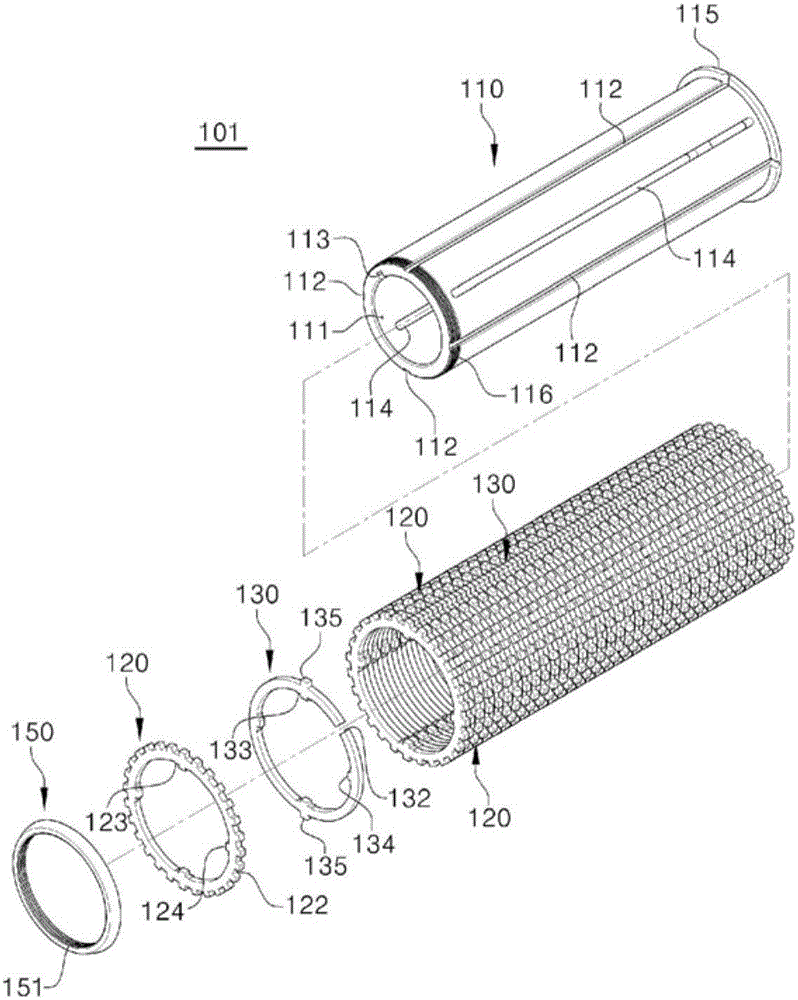

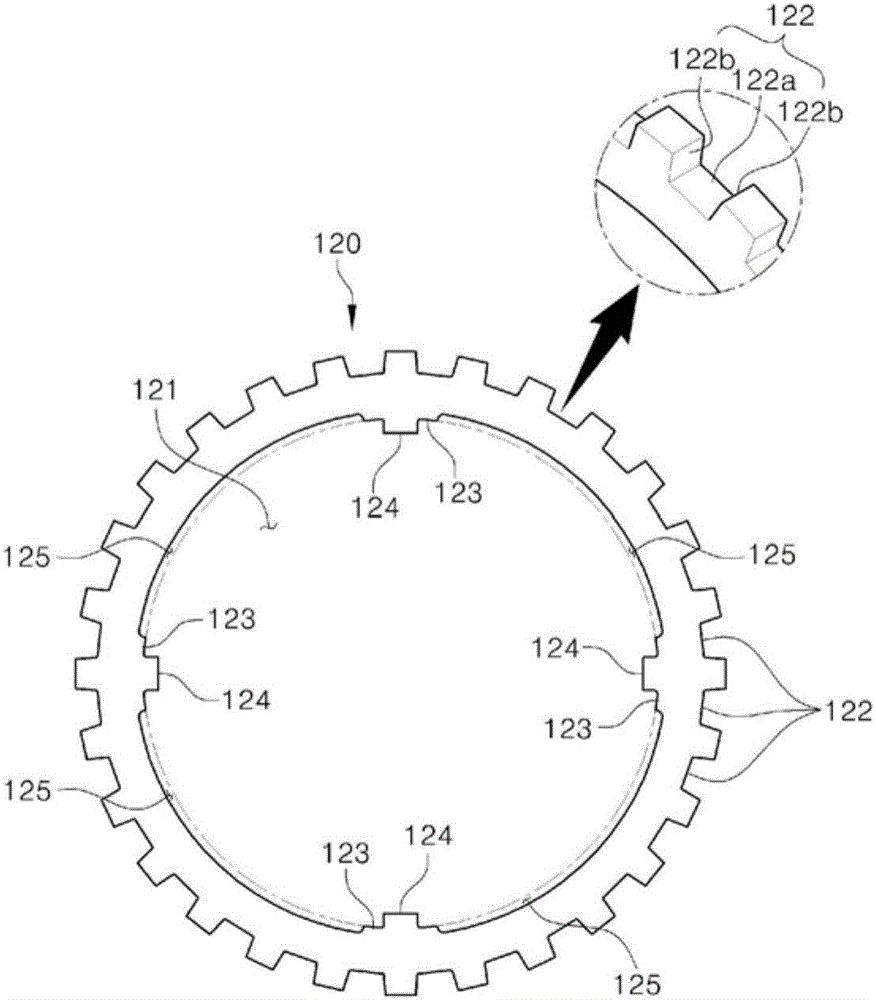

[0030] Hereinafter, respective preferred embodiments of the cutter ring assembly for rice mills according to the present invention will be described in detail based on the respective drawings. In the description, in the description of the cutting ring and the spacer ring having a ring shape, the definition is as follows: one side is the front surface of the ring and the other side is the back side of the ring when viewed from the conveying direction of the rice grains, one side and the other The outer side to which the side faces are connected is called the outer peripheral surface of the ring and the inner side is called the inner peripheral surface of the ring.

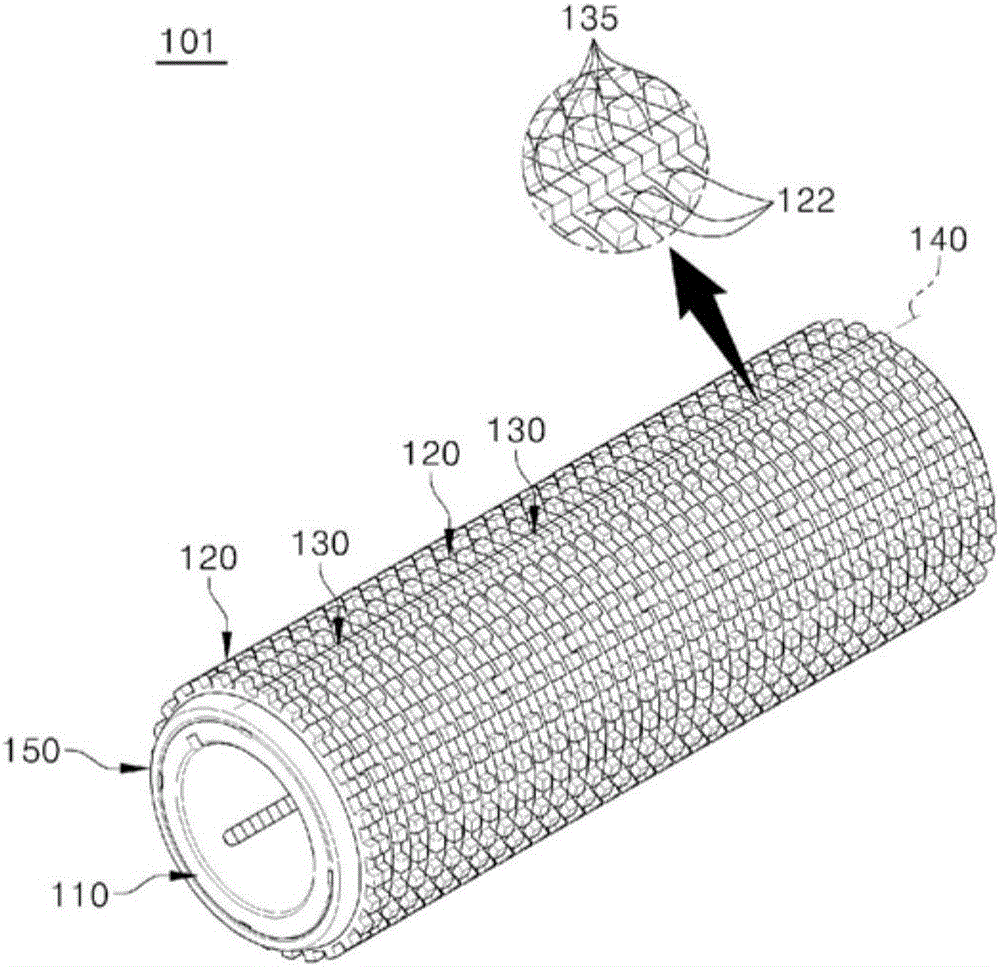

[0031] Figure 1 to Figure 6 A cutting ring assembly for a rice mill used in a small rice mill acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com