Work vehicle and travel region specification device

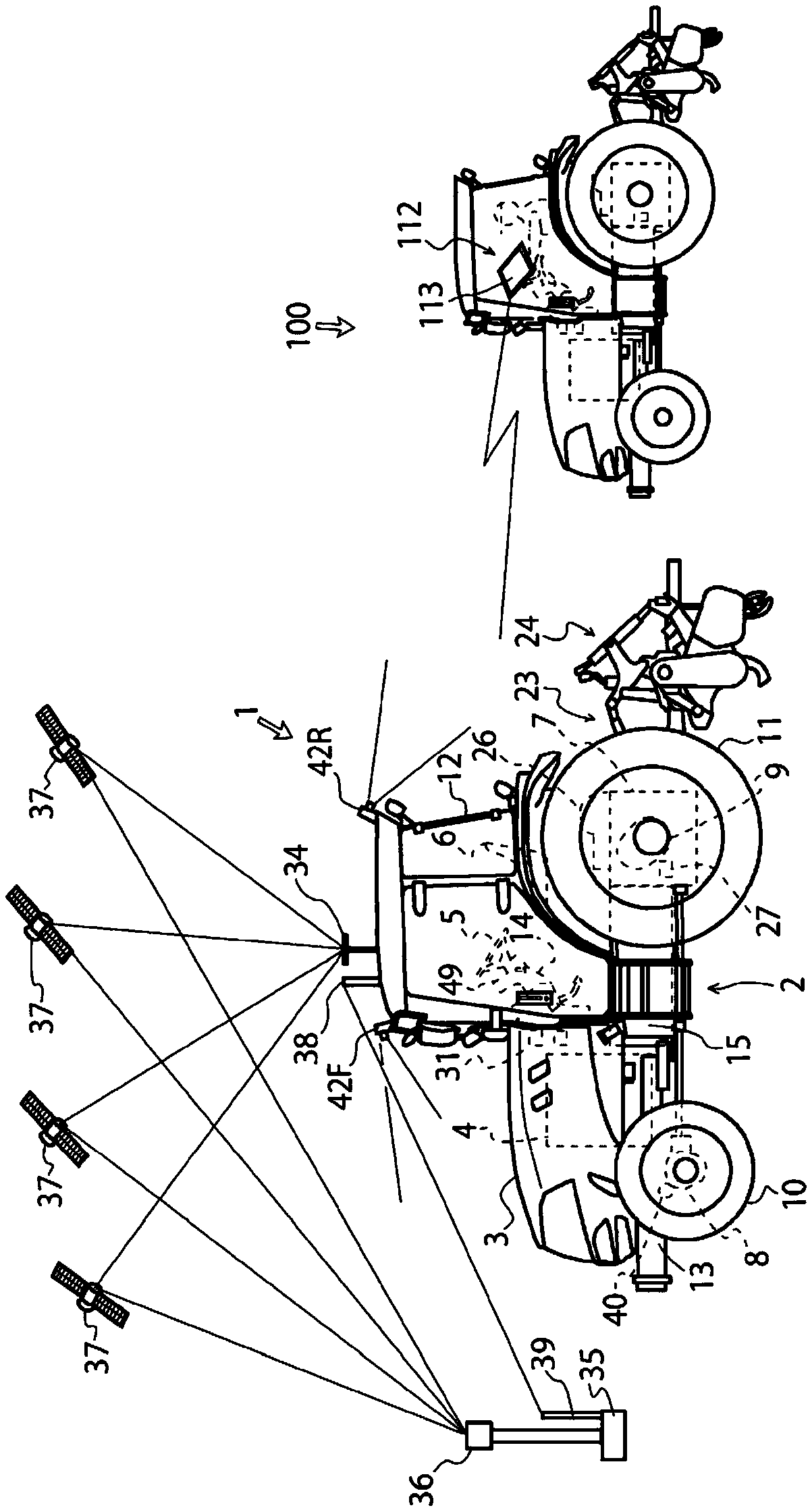

A technology for driving areas and working vehicles, applied in vehicle position/route/height control, agriculture, motor vehicles, etc., can solve the problems of increased labor for operators and inability to start work immediately, and achieve good efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

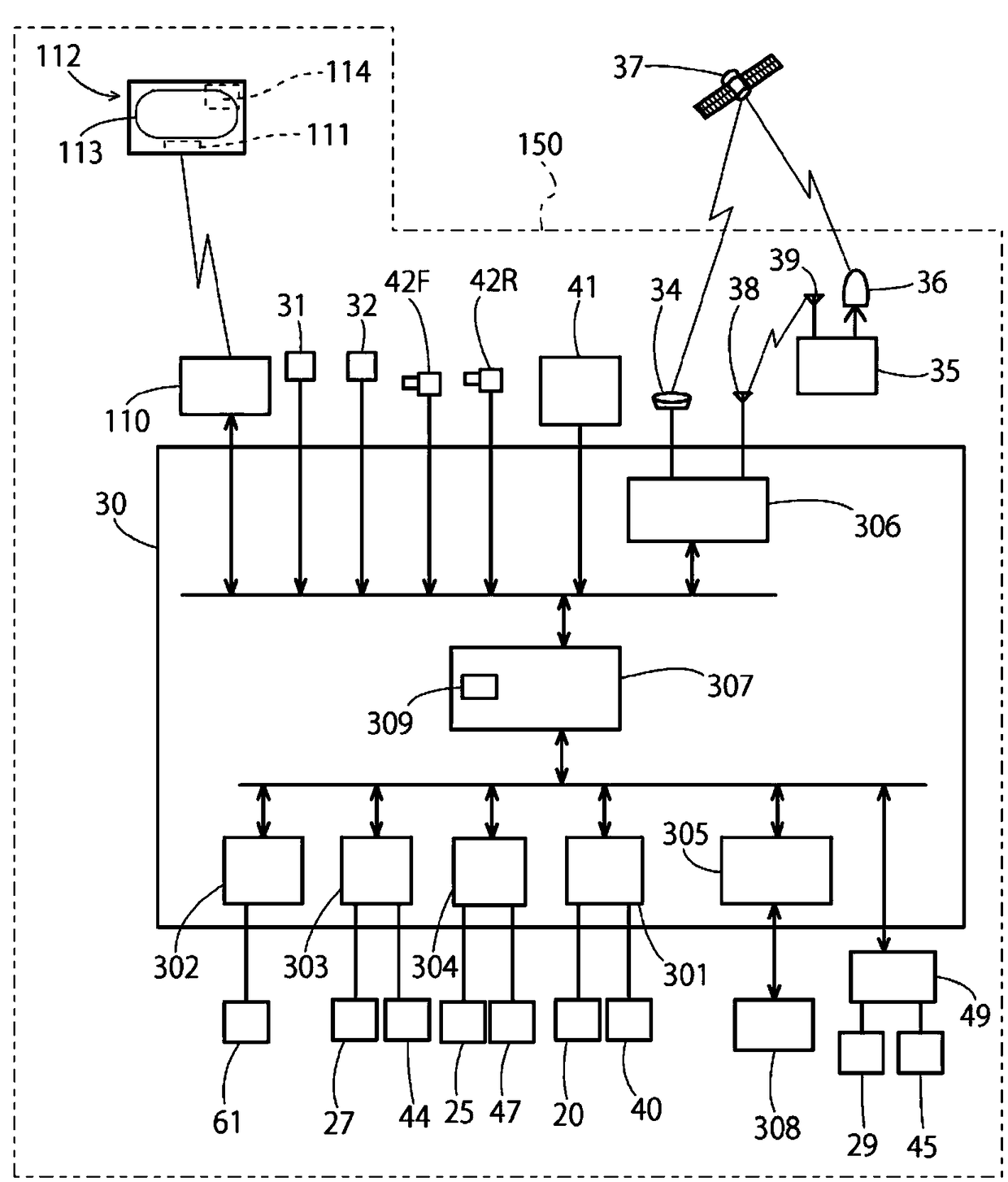

Method used

Image

Examples

no. 1 approach

[0299] Figure 25 An embodiment is shown in which the order of the working paths is determined by skipping two paths toward one side from the working path R1 at the end (work start position S), and from the limit of one side, that is, when one cannot move toward one side. Skip 2 working roads R10 and return to the first working road R2 adjacent to the working road R1 at the end, from here skip 2 roads to one side again to set the running order of the working roads, when reaching the limit After that, return to the second working road R3 adjacent to the working road R1 at the end, and skip two roads to one side again to set the running order of the working roads. Also, the "travel order" is the travel order in the work route Ra generated on the route R, which is the order of the work roads for traveling in the work route Ra from one headland HB to another headland HB.

[0300] Figure 26 This shows an embodiment in which the order of the working lanes is determined by skippin...

no. 2 approach

[0311] Figure 29 An embodiment in which the work start position is changed according to the number of work lanes is shown. Figure 29 , the upper part shows an example where the number of working lanes is set to 12 (a multiple of 3), the middle part shows an example where the number of working lanes is set to 10 (a multiple of 3 - 2), and the lower part shows an example of An example in which the number of work paths is set to 11 (a multiple of 3 - 2) is shown.

[0312]When the number of working roads is 3N (N is a natural number above 4, "3N" is a multiple of 3), the second working road R2 starting from the end is taken as the starting position, When the number is 3N-2, the third working lane R3 from the end is set as the starting position, and when the number of working lanes is 3N-1, the working lane R1 at the end is set as the starting position. Then, after the work start position S (work road to start) is set according to the number of work roads, the running order of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com