Standing corn stalk front-mounted crushing return-to-field machine

A corn stalk and front-mounted technology, which is applied to harvesters, agricultural machinery and implements, cutters, etc., can solve the problems of reducing the operation efficiency of corn stalks, crushing quality of corn stalks, unsmooth transportation of straws, and high failure rate, so as to reduce blockage Probability of failure, improvement of work efficiency, effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

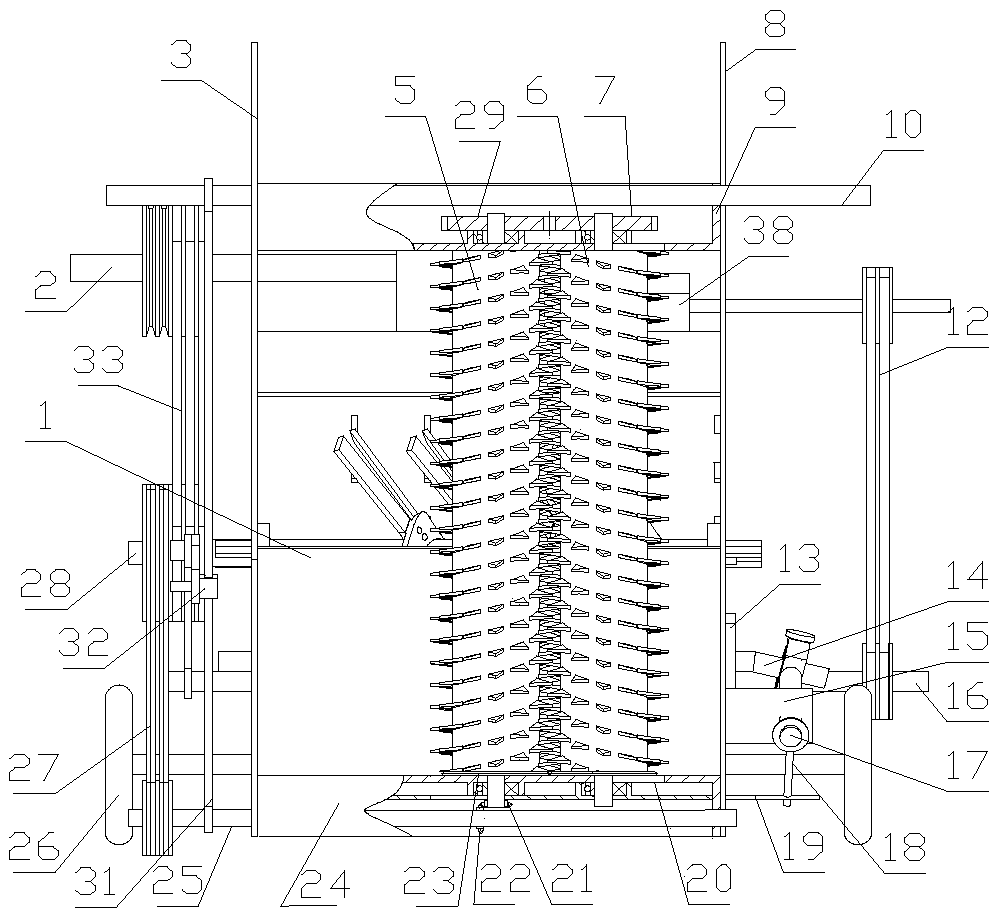

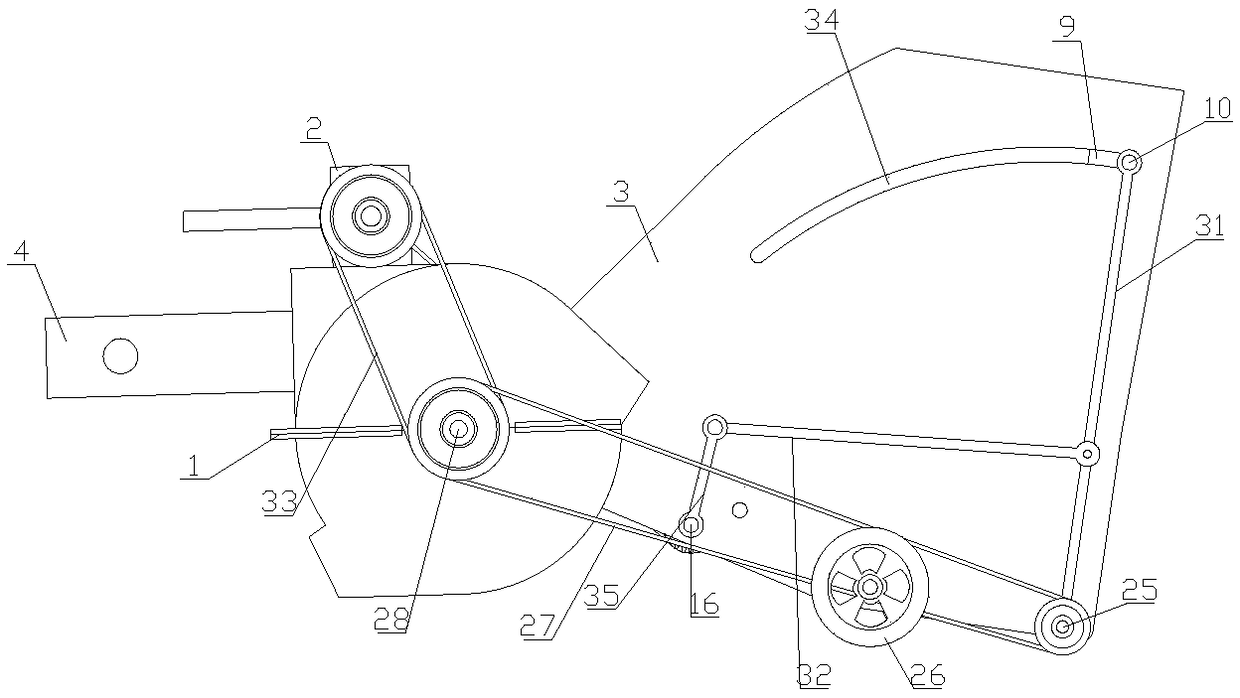

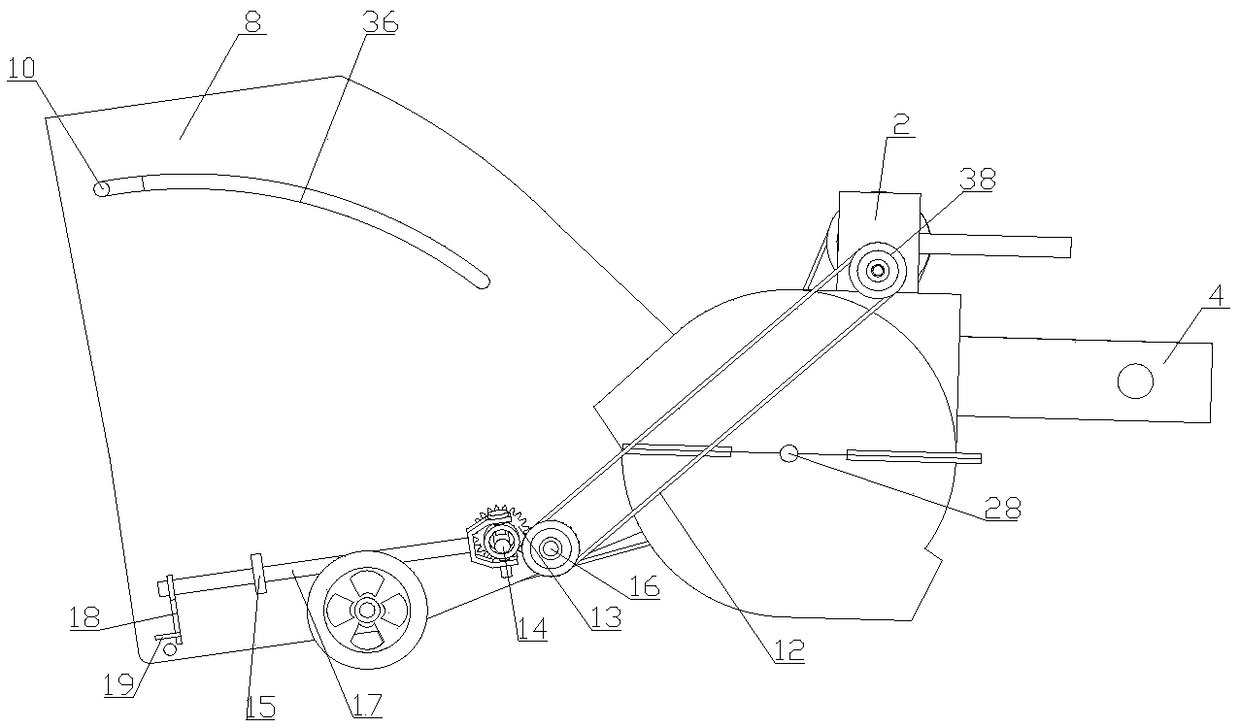

[0013] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A standing corn stalk front crushing and returning machine, in which a power input transmission box 2, a suspension frame 4 and a crushing knife roller assembly 28 are respectively installed on the rear side of the frame assembly 1, and the transmission belt C33 transmits the power to the transmission box 2. It is connected with the crushing knife roller assembly 28. On the left wall plate 8 and the right wall plate 3 of the frame assembly 1, an arc-shaped left slideway 36 and an arc-shaped right slideway 34 are respectively provided symmetrically. 10 is slidably supported and inserted on the arc-shaped left slideway 36 and the arc-shaped right slideway 34, and the gearbox housing 9 is hung and installed on the horizontal axis 10; at the front end of the frame assembly 1 On the rotatable horizontally installed bevel gear drive shaft 25 at the position be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com