Small self-propelled full-width seedling lifting harvester

A self-propelled harvester technology, applied to digging harvesters, harvesters, excavators, etc., can solve the problems of inability to separate Ophiopogon japonicus tubers from the soil, damage the skin of Ophiopogon japonicus tubers, and high work intensity, and achieve It is beneficial to branch reproduction, improving terrain adaptability and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

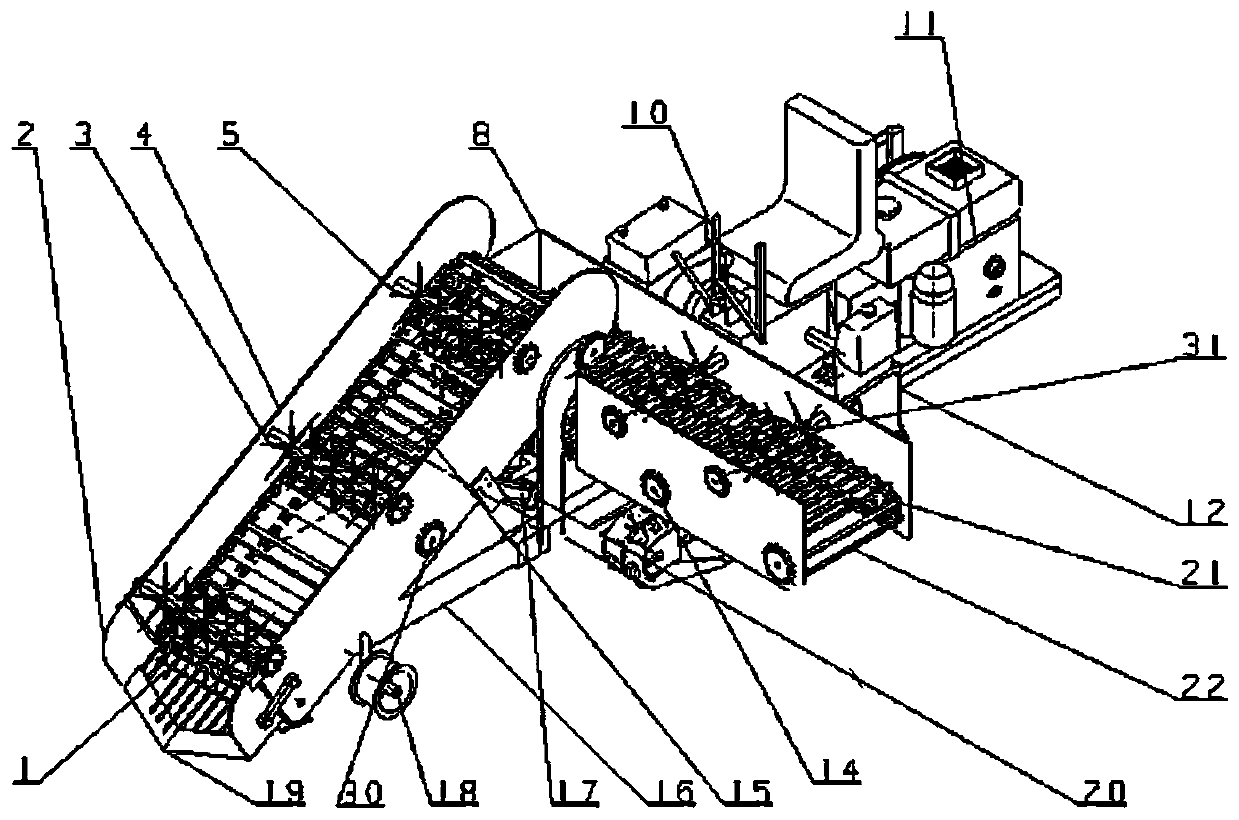

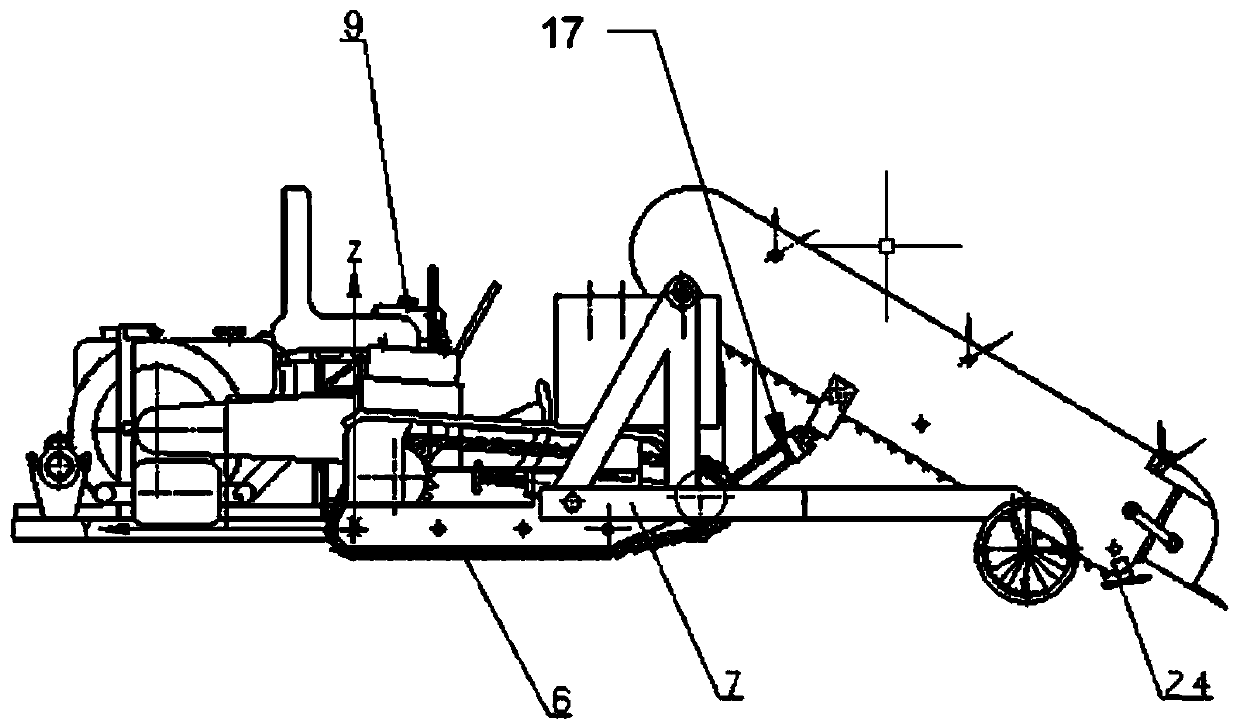

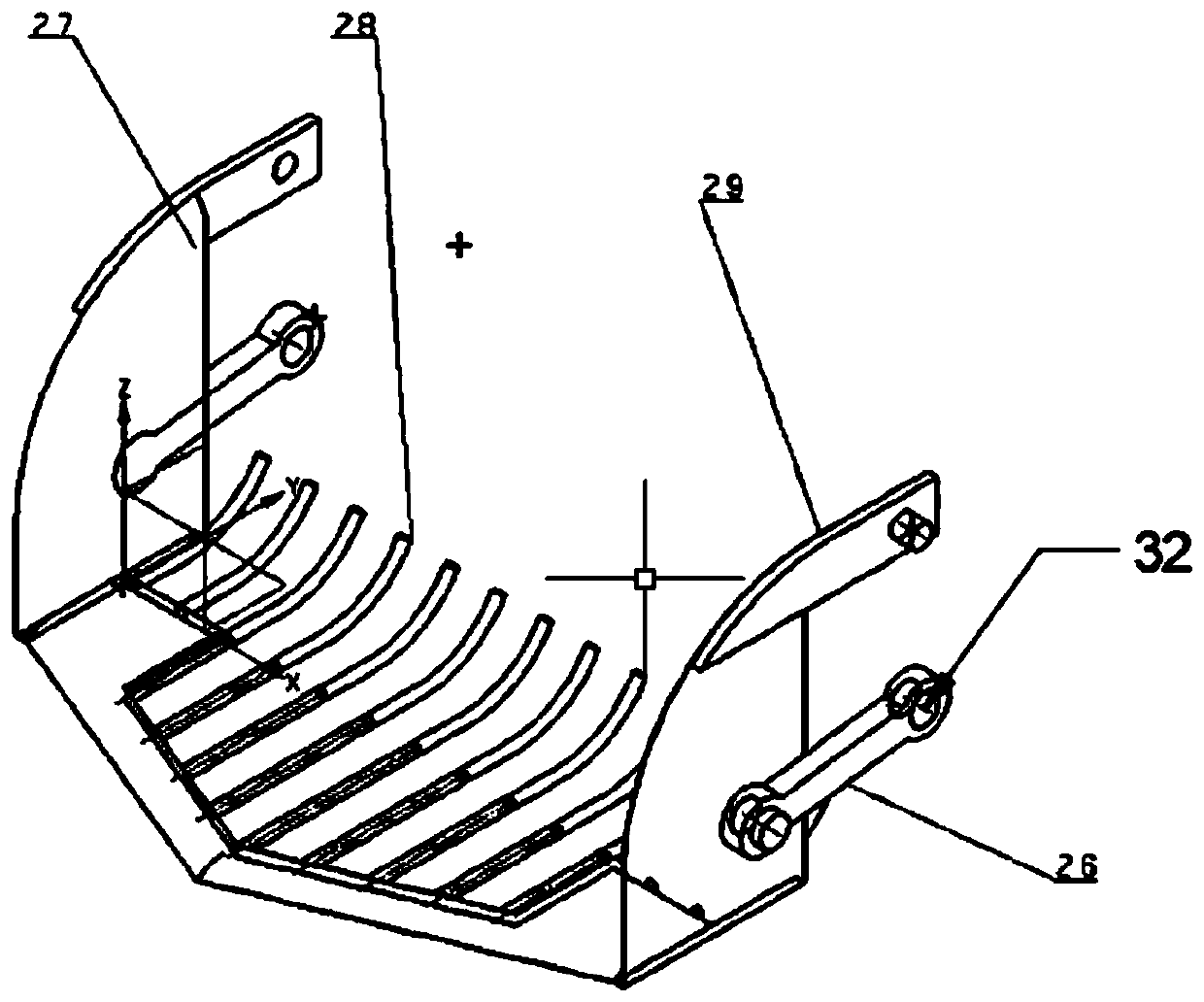

[0070] Such as Figure 1 to Figure 4 As shown, the small self-propelled full-width seedling harvester of the present invention includes an excavating device 2, a conveying device 4, a screening device 8, a hydraulic oil tank 9, a transmission 10, an engine 11, a traveling device 12, a hydraulic cylinder 17, and a depth-limiting wheel 18 , frame 20 and collecting device 22.

[0071] The walking device 12 is located at the rear of the frame 20 , and includes small crawler chassis 6 arranged at the bottom of the frame 20 and on both sides of the frame 20 for walking.

[0072] The transmission 10 , the engine 11 and the hydraulic oil tank 9 are arranged on the frame 20 .

[0073] Narrow crawlers are respectively arranged on both sides of the small crawler chassis 6, and the width of the narrow crawlers is preferably 150-180mm. When harvesting, the width o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com