Corn rootstalk soil removal machine

A technology for removing soil and stubble, which is applied in the fields of collectors, agricultural machinery and implements, agriculture, etc., can solve the problem that corn stubble is not effectively utilized, the quality of stubble chopping and burial is not high, and the next stubble seeds are affected. Implantation and other problems, to achieve the effect of good root-soil separation, novel structural design, and reduced processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]The present invention is described in detail below in conjunction with accompanying drawing:

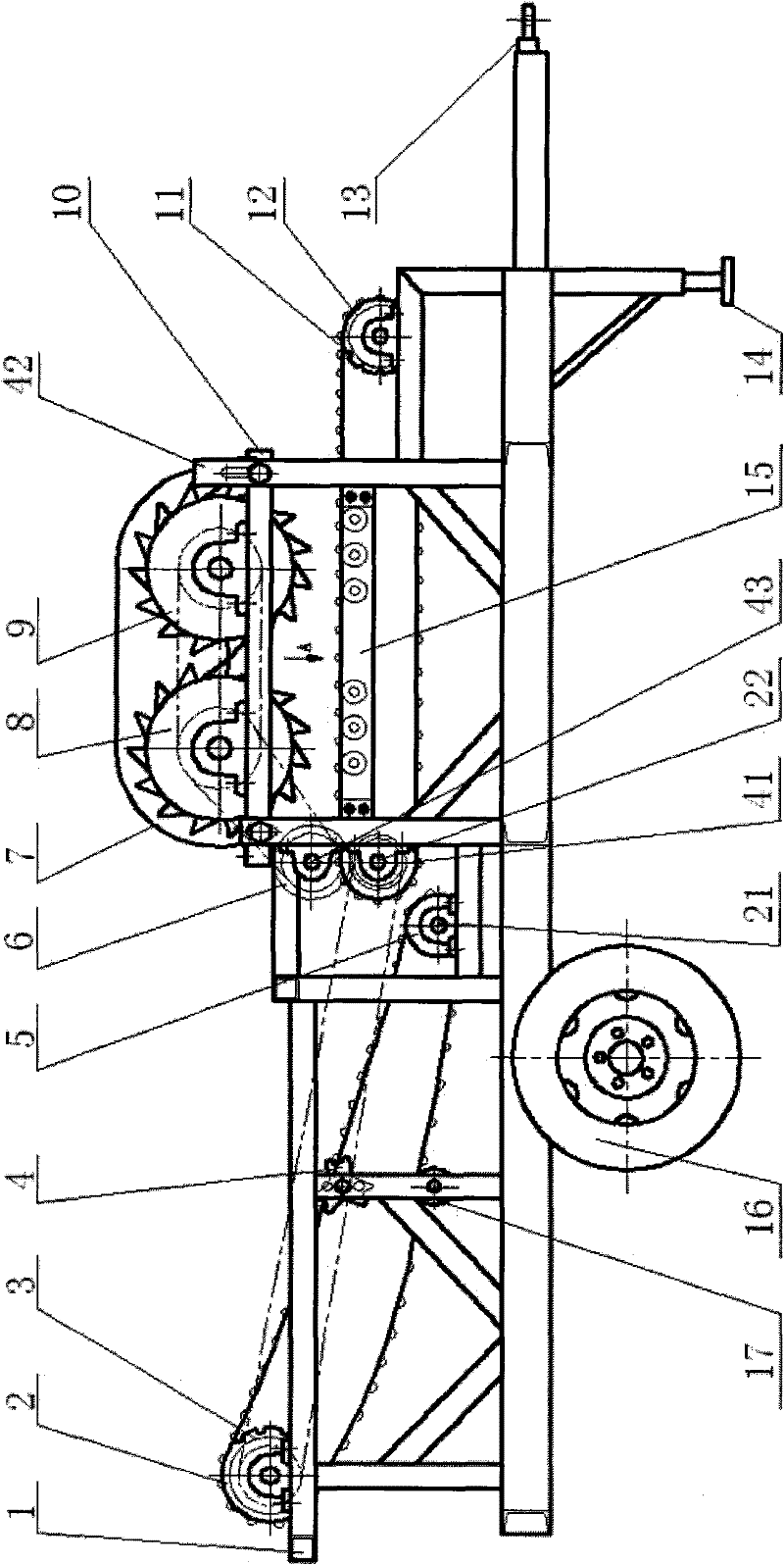

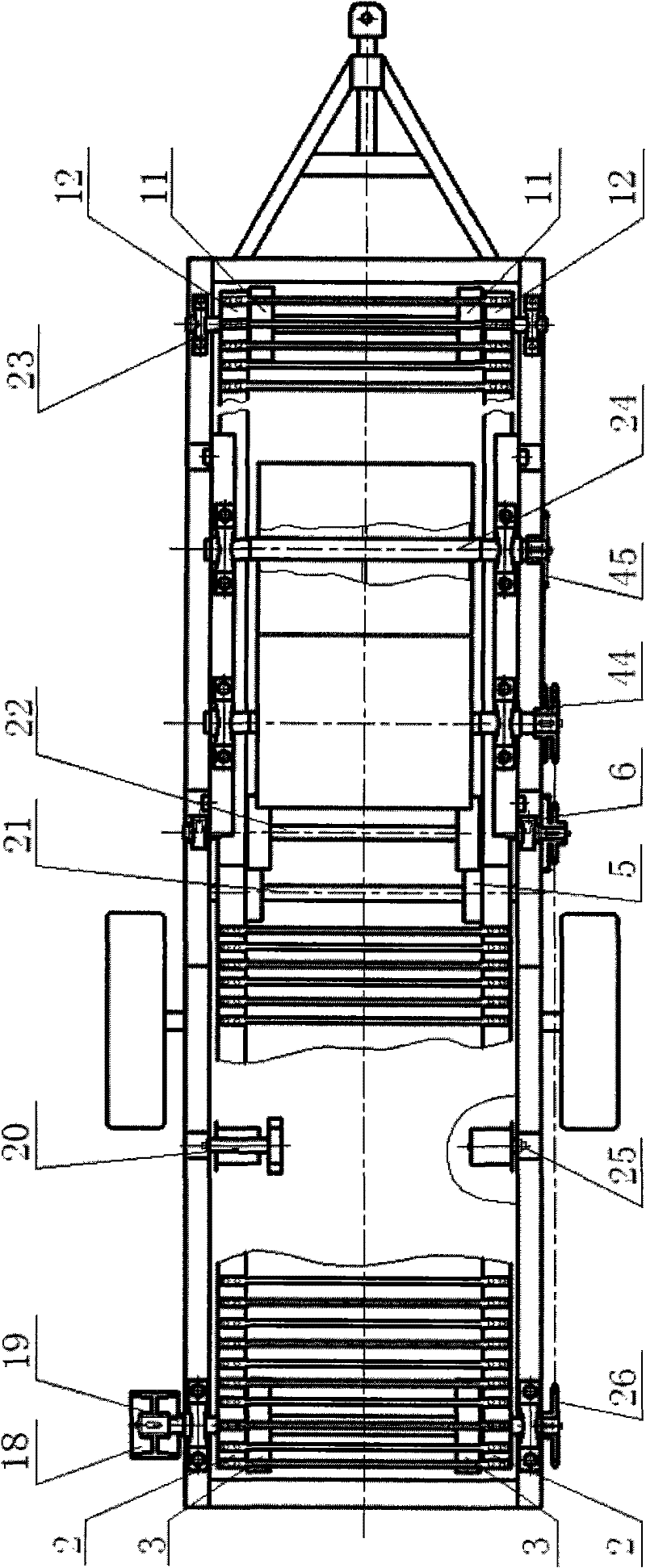

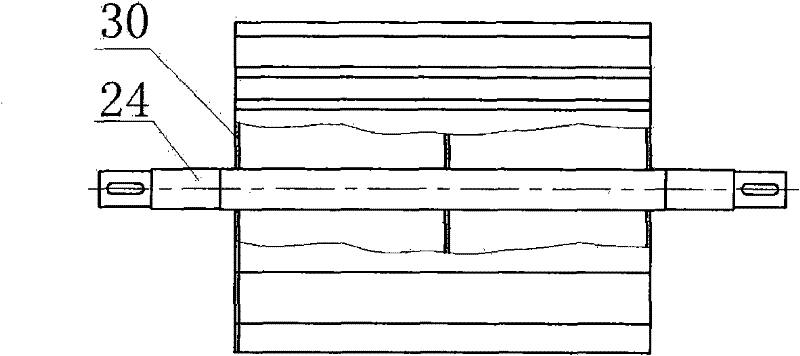

[0022] refer to figure 1 and figure 2 , is the first implementation technical scheme of the corn stubble remover, and the corn stubble remover includes a frame 1, a traction device 13, a double-roller crushing device, and a belt-type bar chain conveying and feeding mechanism , Rod chain vibration separation mechanism, road wheel mechanism and transmission system.

[0023] The frame 1 is a three-dimensional frame structure, which is composed of a main longitudinal beam frame and an auxiliary frame.

[0024] The main longitudinal beam frame is the carrier of the main mechanisms of the corn stubble remover. The main longitudinal beam frame is a planar frame structure made of two main longitudinal beams made of profiled tubular steel and several small beams made of profiled tubular steel through welding, riveting or / and bolting.

[0025] The auxiliary frame is the carrier of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com