Elastic vibratory deep scarification unit

A vibrating and deep loosening technology, applied in the field of agricultural machinery, can solve the problems of unsatisfactory deep loosening and crushing, complicated and difficult adjustment operations, and high consumption of traction power, and achieves a simple structure, wide application range and low manufacturing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

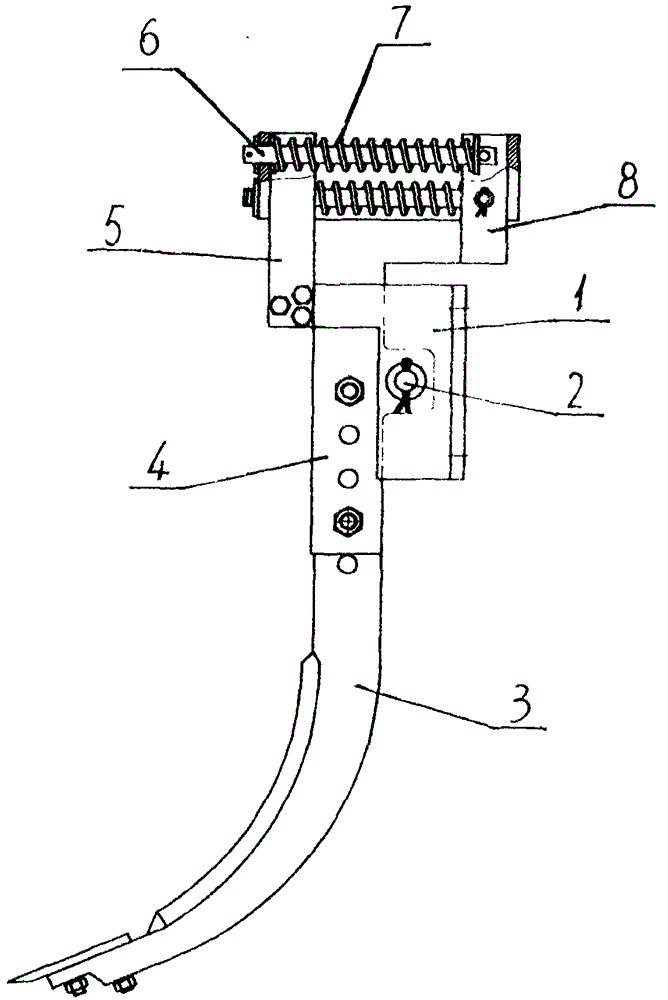

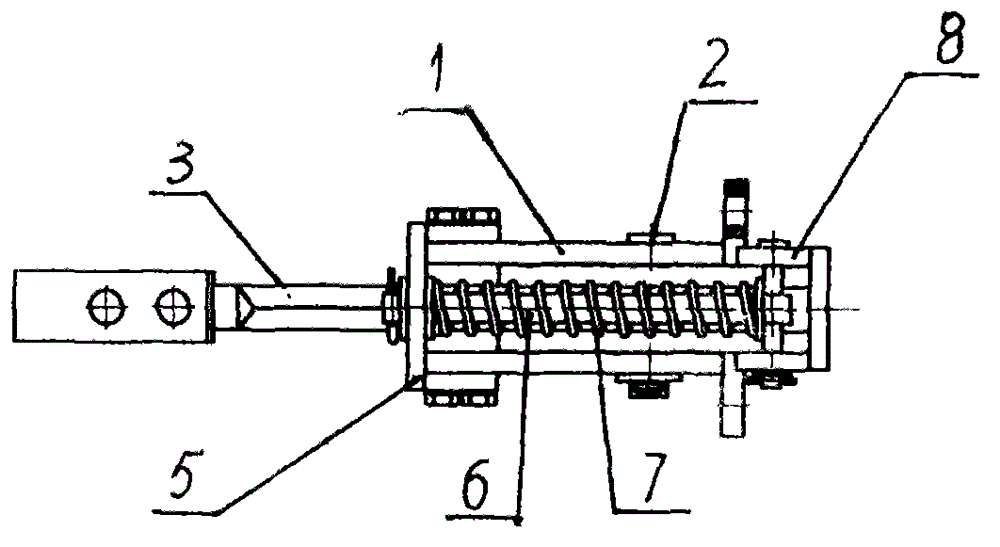

[0010] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. An elastic vibration-type subsoiling unit, on which a shovel seat 4 is installed on the assembly frame 1 through a pin shaft 2, and the subsoil crushing shovel assembly 3 can be moved up and down and adjusted to fit on the shovel seat 4, and the subsoil crushing shovel assembly 3 can be adjusted to fit on the shovel seat 4. The spring pressure plate 8 is fixed on the rear side of the upper end of the shovel assembly 3, the spring positioning plate 5 is fixedly fitted on the upper front end of the assembly frame 1, and the front side of the spring shaft 6 is axially movable inserted on the spring positioning plate 5, The spring shaft 6 rear end is hingedly connected with the spring pressure plate 8, and the pressure spring 7 is sleeved on the spring shaft 6, and the front and rear end surfaces of the pressure spring 7 contact and cooperate with the spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com