Rotary drum type rotary cultivator

A rotary tiller and drum-type technology, which is applied in the field of drum-type rotary tillers, can solve the problems of inconvenient maintenance of damaged parts, low strength of rotary tiller parts, and low efficiency of crushing soil, so as to achieve convenient maintenance, good effect of crushing soil, and The effect of high farming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

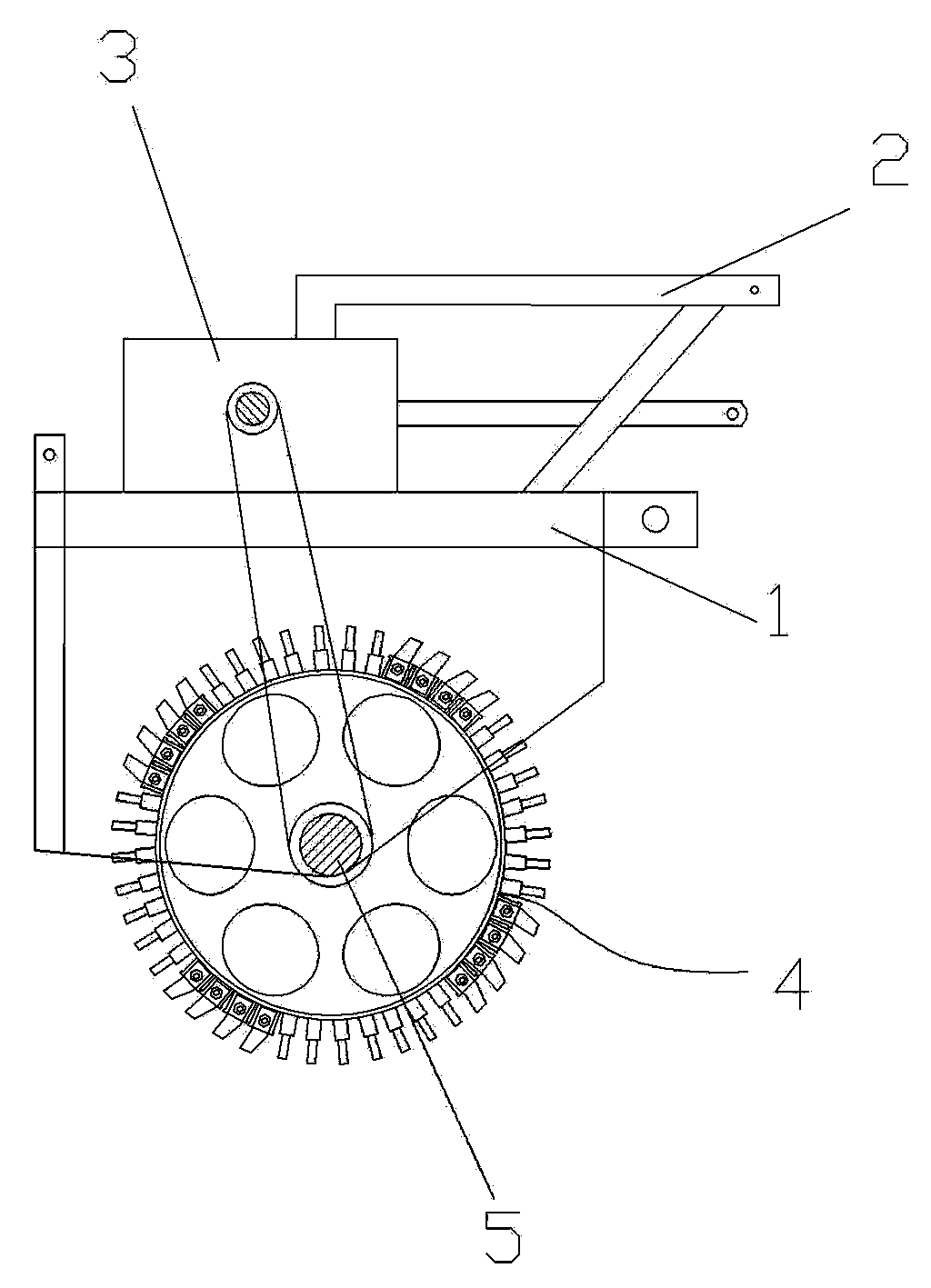

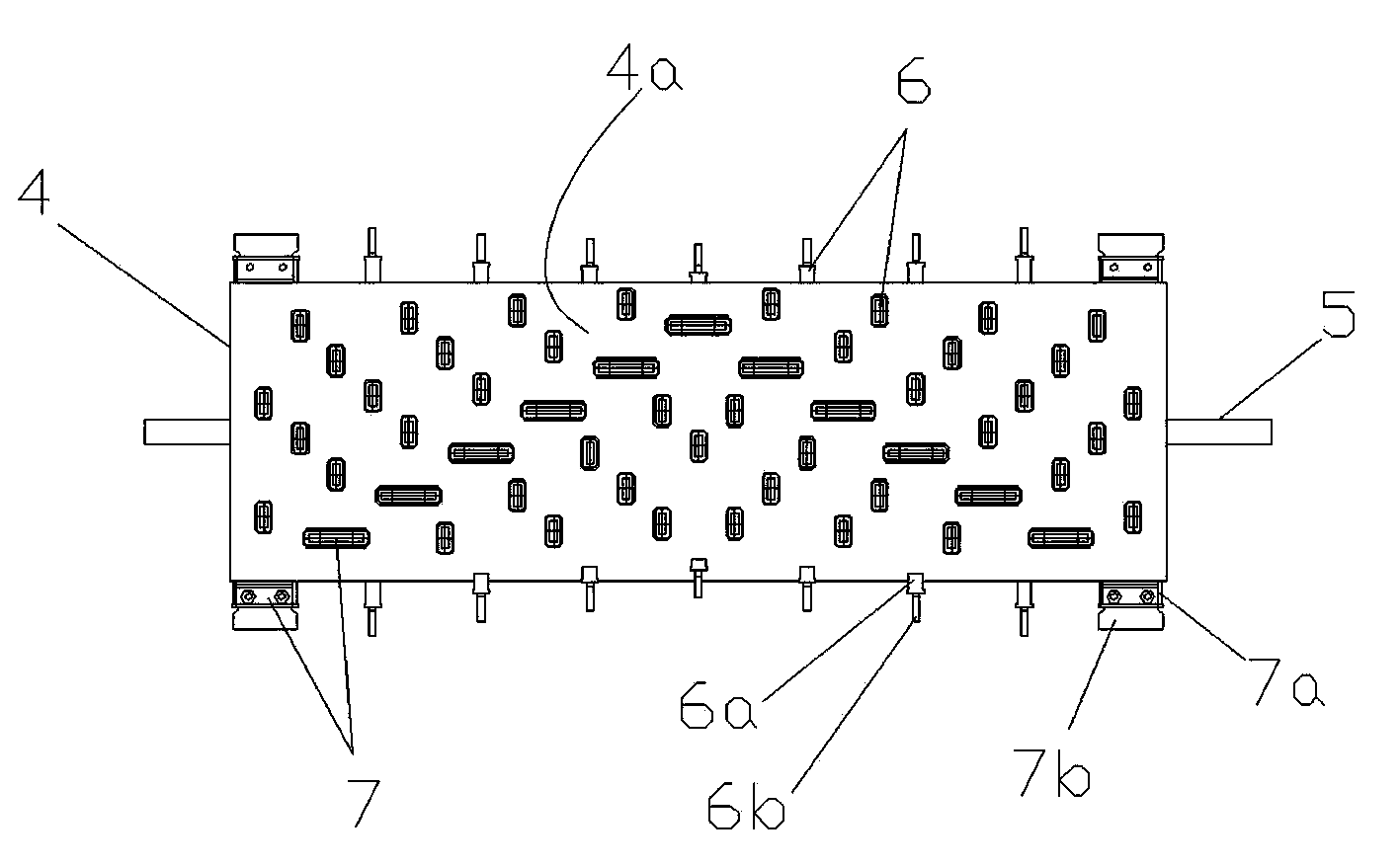

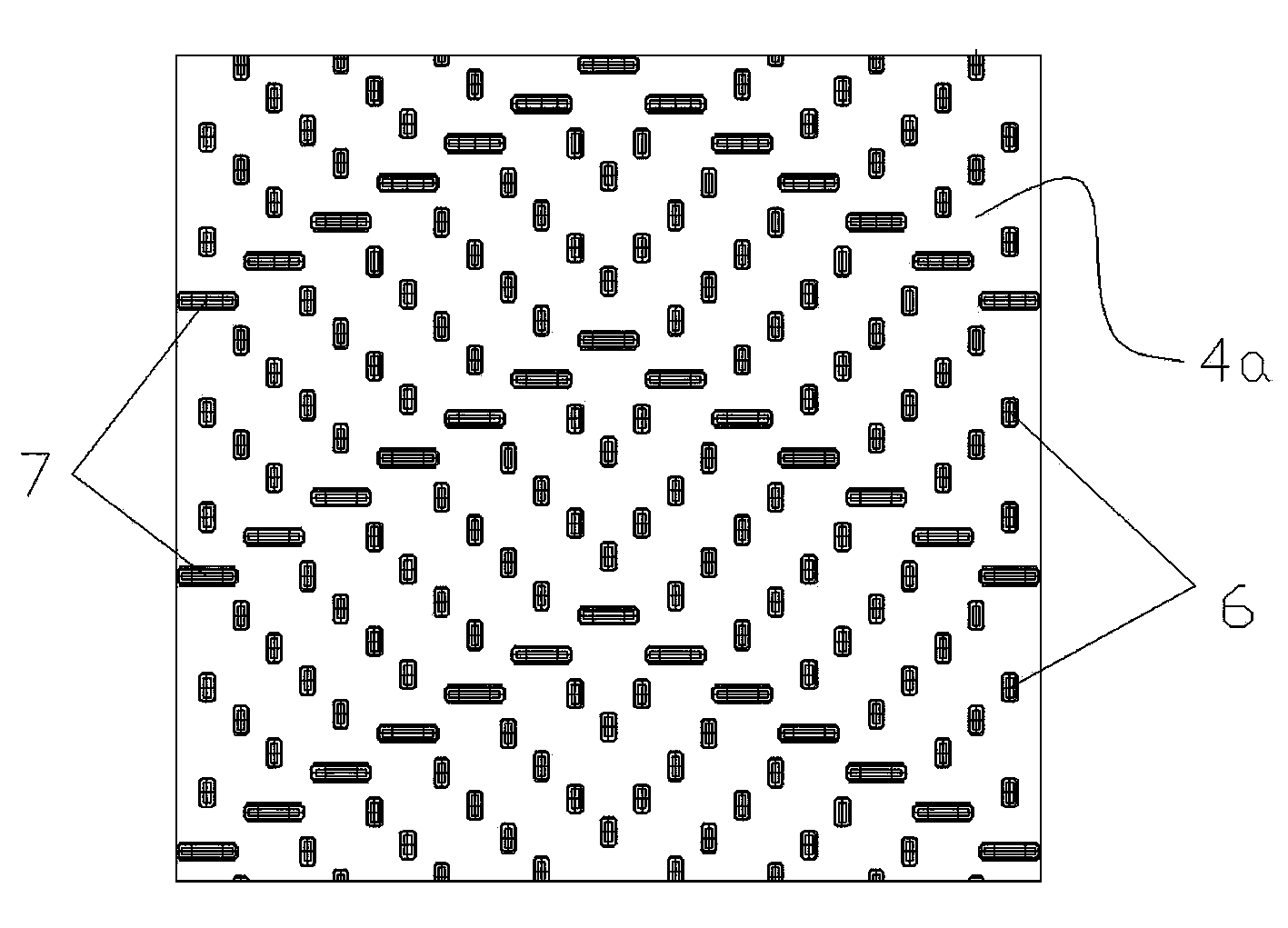

[0021] Such as figure 1 , 2 As shown, a drum type rotary tiller includes: a traction frame 2 and a transmission assembly 3 are arranged on the frame 1, and the transmission assembly 3 is composed of a gearbox 3a, a transmission shaft 3b, and a sprocket 3c , because it belongs to the prior art so the following will not go into details, the drum rotary tillage assembly 4 is set, the drum rotary tillage assembly 4 is provided with a main shaft 5, the two ends of the main shaft 5 are connected with the frame 1, and connected with the transmission assembly 3 to form a transmission fit, and the rotary tiller assembly 6 and at least one set of moldboard assemblies 7 are evenly distributed on the drum surface 4a of the drum rotary tillage assembly 4 .

[0022] Since the present invention adopts the drum rotary tillage structure, compared with the traditional knife-roller rotary tillage structure, more rotary tiller assemblies can be installed on the drum, thereby achieving the purpos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com