Draw bench knife roll

A technology of rod pulling machine and knife roller, which is applied in the direction of harvesters, agricultural machinery and implements, etc., can solve problems such as leakage of rods, heavy stress on the tool, and easy damage to the tool, so as to improve the service life and reduce the Small vibration and impact, reducing wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the purpose, technical solution and advantages of the present invention clearer, the invention will be further described in detail with the accompanying drawings.

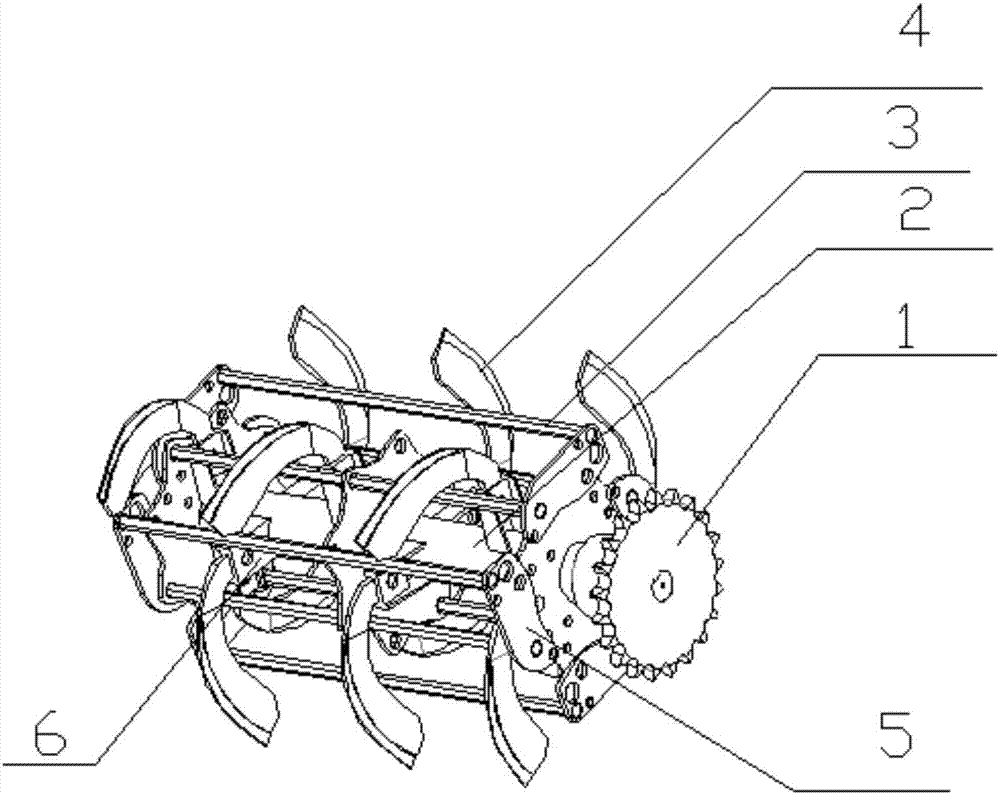

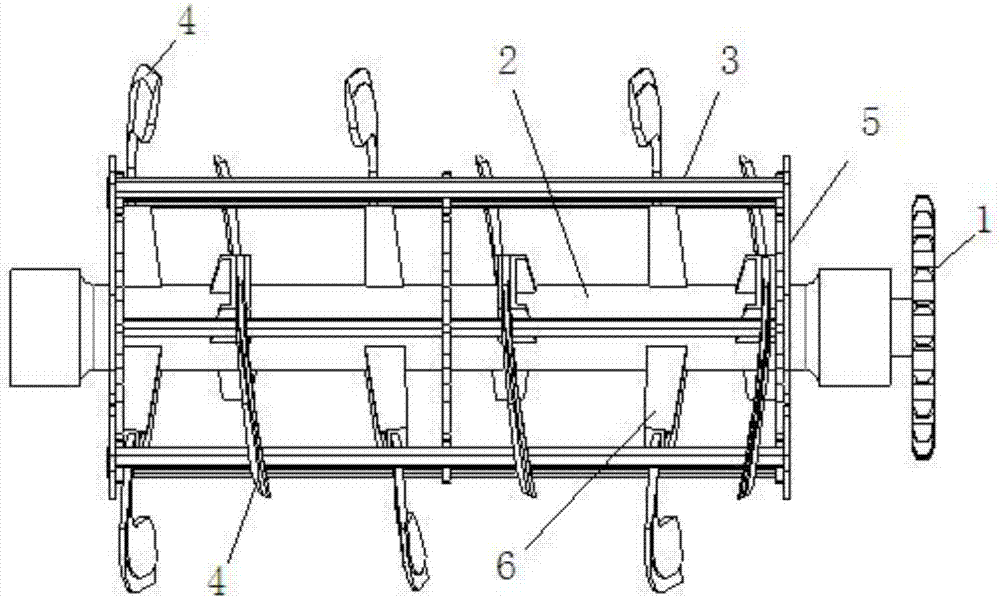

[0014] Refer to attached figure 1 with figure 2 , the present embodiment provides a bar pulling machine knife roller, including a knife roller driving sprocket 1, a knife roller shaft 2, a cross bar 3 and a rotary tiller machete 4, and the knife roller driving sprocket 1 is installed and fixed on the knife roller shaft 2 One end is used for transmission link with the driving device. The cross bar 3 is a hexagonal square steel rod used to overwhelm the tobacco stalk. Parallel to each other, multiple groups of installation panels 5 are fixedly arranged on the cutter roller shaft 2 along the length direction, and the two ends of the cross bar 3 are respectively fixed on the outermost installation panels 5 at both ends of the cutter roller shaft 2, and the cutter roller shaft The outer side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com