Single-power-input and multi-direction multi-power-output transmission device

A technology of power output and transmission, which is applied in the direction of transmission, transmission parts, gear transmission, etc., can solve the problems of difficulty in improving productivity, single power output structure, and limited horticultural production, so as to reduce the number of land entry, The effect of saving oil and increasing the efficiency of agricultural production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

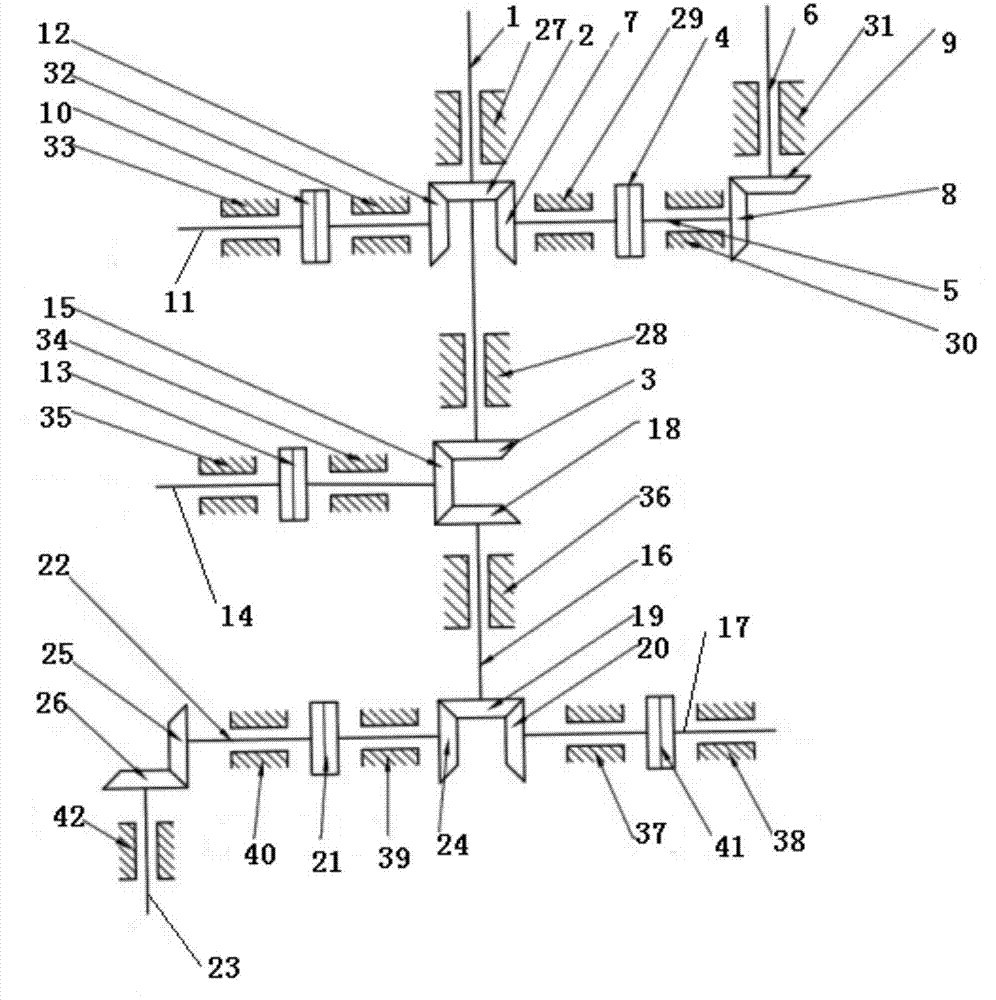

[0018] refer to figure 1 , the present invention proposes a transmission device with single power input, multiple directions and multiple power outputs, including a box for storing cooling oil and a power input mechanism and a power output mechanism arranged in the box, wherein:

[0019] The power input mechanism includes a longitudinally arranged power input shaft 1 , which obtains rotational speed and torque from the vehicle transmission system through a power take-off. The power input shaft 1 is provided with a first bevel gear 2 and a second bevel gear 3 . The power input shaft 1 is installed on the box through the first tapered roller bearing 27 and the second tapered roller bearing 28, and the first tapered roller bearing 27 and the second tapered roller bearing 28 are installed in reverse, so that the power transmission can be balanced When the axial force and radial force generated by the power input shaft 1, and prevent the axial movement of the power input shaft 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com