Double-ridge shaping efficient environmentally-friendly film placement machine

A laying machine and environmental protection technology, which is applied in plant protection, plant protection cover, agricultural machinery and tools, etc., can solve the problems of low recovery rate and operation efficiency, and large change of ridge shape, so as to reduce the number of times of entering the field and improve the work efficiency. Efficiency, the effect of improving the recovery rate and recovery efficiency of plastic film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings.

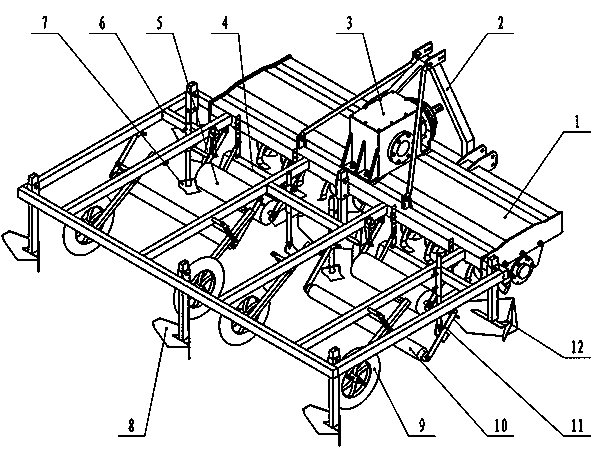

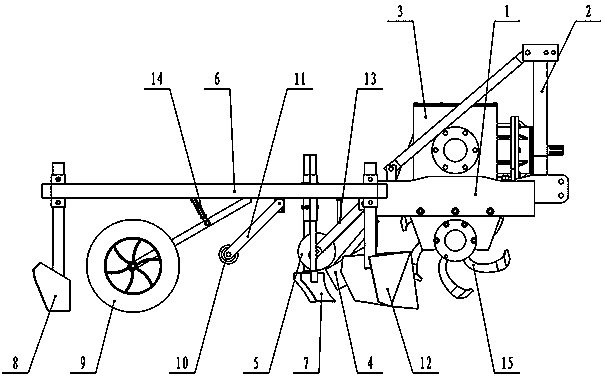

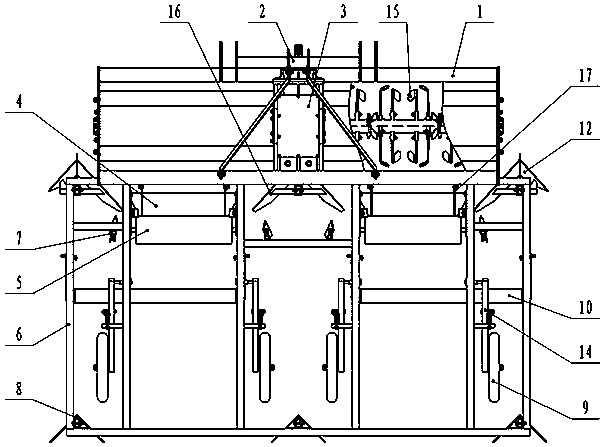

[0016] as attached figure 1 , attached figure 2 , attached image 3 As shown, a double ridge shaping and high-efficiency environmental protection film laying machine is mainly composed of a rotary tillage frame 1, a traction frame 2, a gearbox 3, a shaper 4, a ridge top compacting roller 5, a film laying frame 6, and a film edge Ditching shovel 7, film side covering soil shovel 8, film pressing wheel 9, film roll 10, film roll installation plate 11, side ridging shovel 12, compacting roller arm 13, film pressing wheel arm 14, rotary tiller 15, middle Ridging shovel 16 and shaper arm 17 are formed. Rotary tiller 15 is installed on the bottom of rotary tiller frame 1, and its single-side rotary tiller is in the mode of opposite installation, which ensures that the unscrewed soil will not be thrown to the outside. The traction frame 2 is installed on the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com