Film-covered corn straw crushing and collecting type residual film recycling machine

A corn stalk and recovery machine technology, applied in the field of agricultural machinery, can solve the problems of increasing mulch film damage, high degree of mulch mechanical damage, and high residual root stubble, so as to improve the recovery rate of residual film, reduce the degree of mechanical damage, and reduce the number of times of entry into the field Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

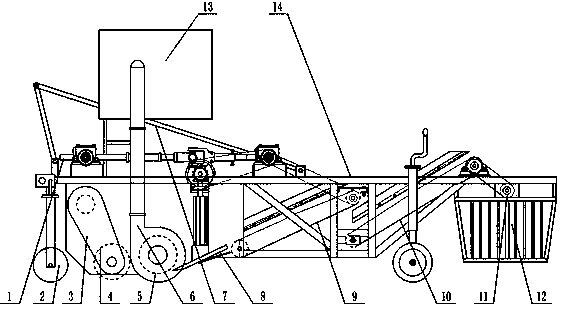

[0009] Example 1, see figure 1 Among them, the upper end of the frame (14) is provided with a straw collection box (13), the suspension mechanism (7) and the transmission shaft (1), and the lower end of the frame (14) is provided with a transmission device (3), and the transmission device (3) The left end of the straw is provided with a straw stubble depth limiting wheel (2), the lower end of the transmission device (3) is provided with a cutter shaft assembly (4), and the right end of the transmission device (3) is provided with a screw conveying device (5), straw pneumatic lift Assembly (6), the right end of the straw pneumatic lifting assembly (6) is provided with a film lifting shovel (8), the right end of the film lifting shovel (8) is provided with a primary lifting chain (9), and a primary lifting chain (9 ) is provided with a secondary lifting chain (10), the right end of the secondary lifting chain (10) is provided with a reel assembly (11), and the lower end of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com