Harrow and plow compound machine

A working machine and duplex technology, applied to agricultural machinery and tools, plows, agriculture, etc., can solve the problems of increased equipment equipment, increased operating procedures, and low operating efficiency, so as to reduce the number of times of entering the field, reduce operating costs, and have reliable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is further described below in conjunction with embodiment and accompanying drawing.

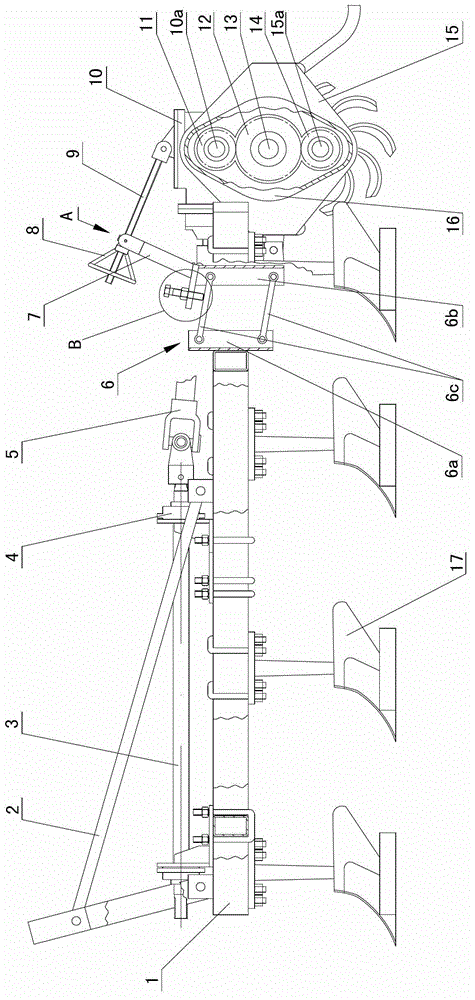

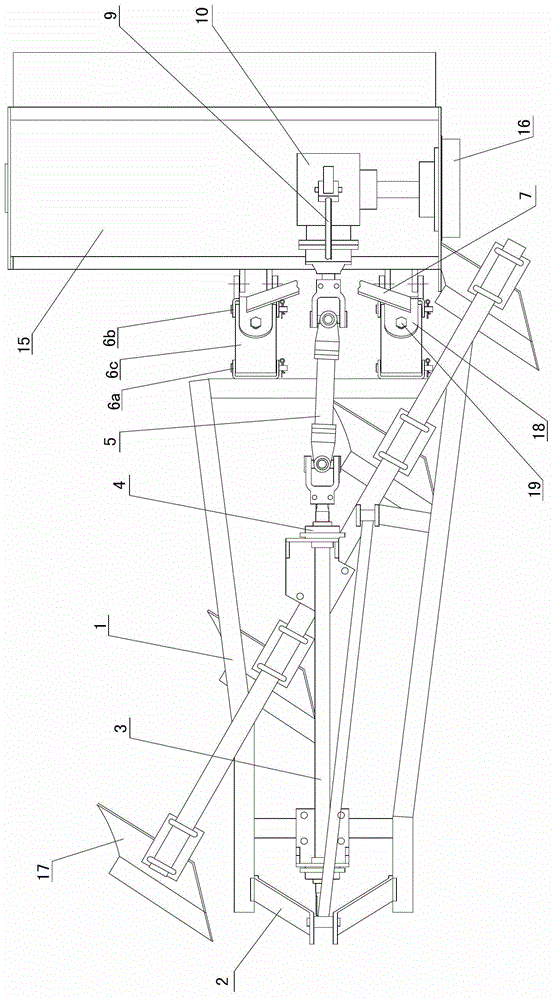

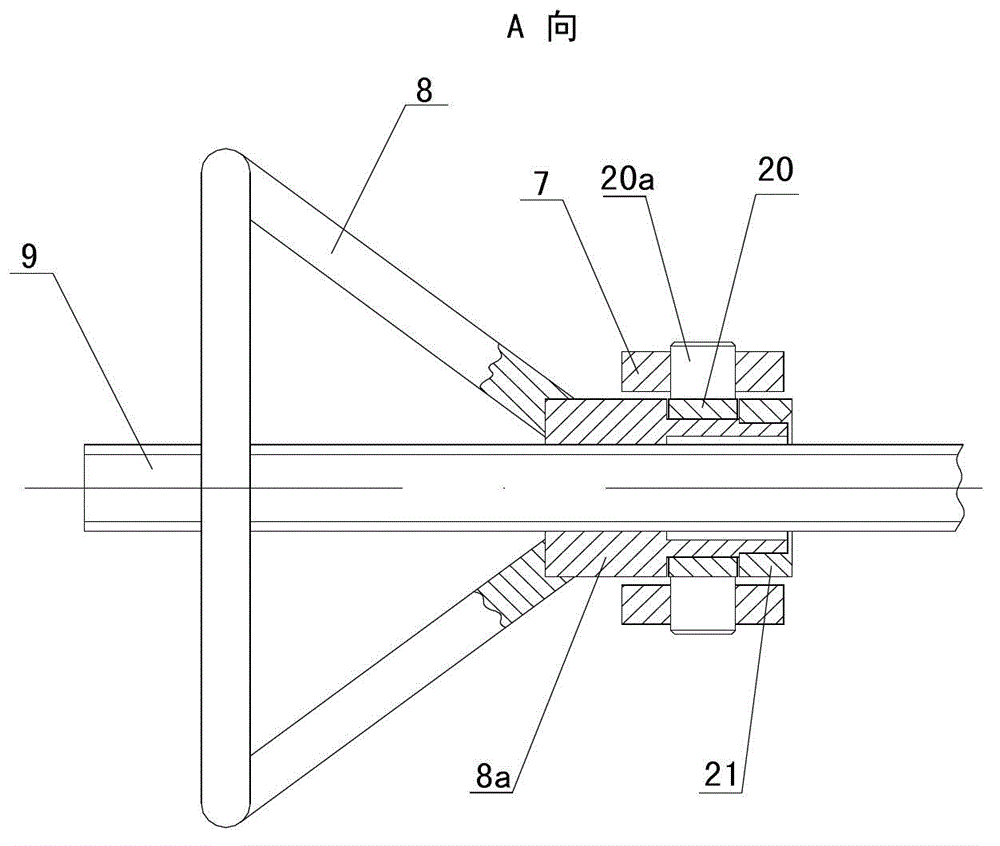

[0012] see figure 1 , figure 2

[0013] The plowing and plow compound operation machine provided by the present invention has a plow frame 1 on which a traction frame 2 and a group of plowshares 17 are installed. The rear is provided with a rotary cultivator 15. A pair of parallel four-bar linkages 6 is arranged between the plow frame 1 and the rotary cultivator 15, and each parallel four-bar linkage 6 is composed of a first support 6a, a second support 6b and a pair of swing rods 6c. The rear end of the plow frame 1 is fixedly connected to the first support 6a of a pair of parallel four-bar linkages, and the rotary tiller 15 is hinged to the second support 6b of a pair of parallel four-bar linkages. A drive shaft 3 is supported on the plow frame 1 by a bearing seat 4, a speed reducer 10 is fixed on the top of the rotary cultivator 15, and the drive shaft is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com