Total collecting and covering no-tillage operation method for corn straw

A corn stalk and working method technology, which is applied in the field of no-tillage operation method covered by the full amount of stalks, can solve the problems of many corn planting and production links, difficulty in ensuring the quality of sowing, low acceptance by farmers, etc., so as to improve land permeability and The effect of arableability, reduction of fertilizer input, and reduction of pesticide use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

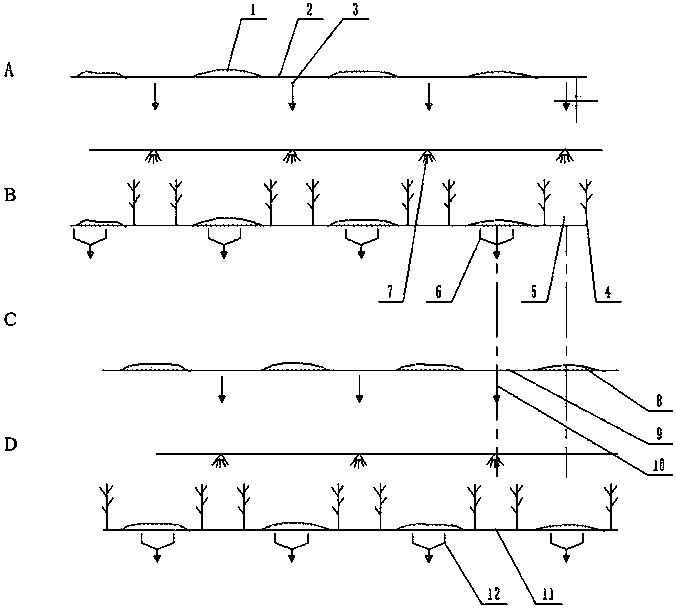

[0029] A no-tillage operation method for full-scale collection of straw and mulching, which takes two years as a cycle, including the first year and the second year of implementation.

[0030] The first year of implementation includes the following steps:

[0031] Step 1. Land plot selection: Suitable for mechanized operation areas, the cultivated soil layer is greater than 40 cm, the land slope is less than 10°, and the cultivated layer has no obstacles such as stones and tree roots.

[0032] Step 2. Straw treatment: use 4-row corn harvesters such as John Deere and Bravery to harvest corn, turn the straw returning machine on the corn harvester, crush the corn stalks in the harvested field into about 10 cm, and sprinkle them on the cultivated land surface.

[0033] Step 3. Straw collection: In autumn, use 40-60 horsepower tractors to hang rear-mounted 2-row or 4-row straw collection machines and other equipment to clean and collect the corn stalks scattered on the ground to f...

Embodiment 2

[0041] A no-tillage operation method for covering rows with full amount of straw, with a cycle of two years, including the first year and the second year of implementation.

[0042] The first year of implementation includes the following steps:

[0043] Step 1. Land plot selection: Suitable for mechanized operation areas, the cultivated soil layer is greater than 40 cm, the land slope is less than 10°, and the cultivated layer has no obstacles such as stones and tree roots.

[0044] Step 2. Straw treatment: If it is harvested manually, the corn stalks stand in the field, and the 904 tractor can be used to hang a separate straw returning machine to crush all the straws standing centimeters in the field into about 10 centimeters and sprinkle them on the surface of the cultivated land.

[0045] Step 3 + Step 4, Straw collection + autumn subsoiling: use 604 or 704 tractors, hang 2 rows of straw collection machines in front of the tractor, and hang 2 rows of subsoilers at the back ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com