Double-row holing device for tobacco field

A tobacco field and driving device technology, applied in the direction of excavation/covering trenches, planting methods, applications, etc., can solve problems such as small size, inaccurate hole spacing, and unreasonable structural size of the auger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

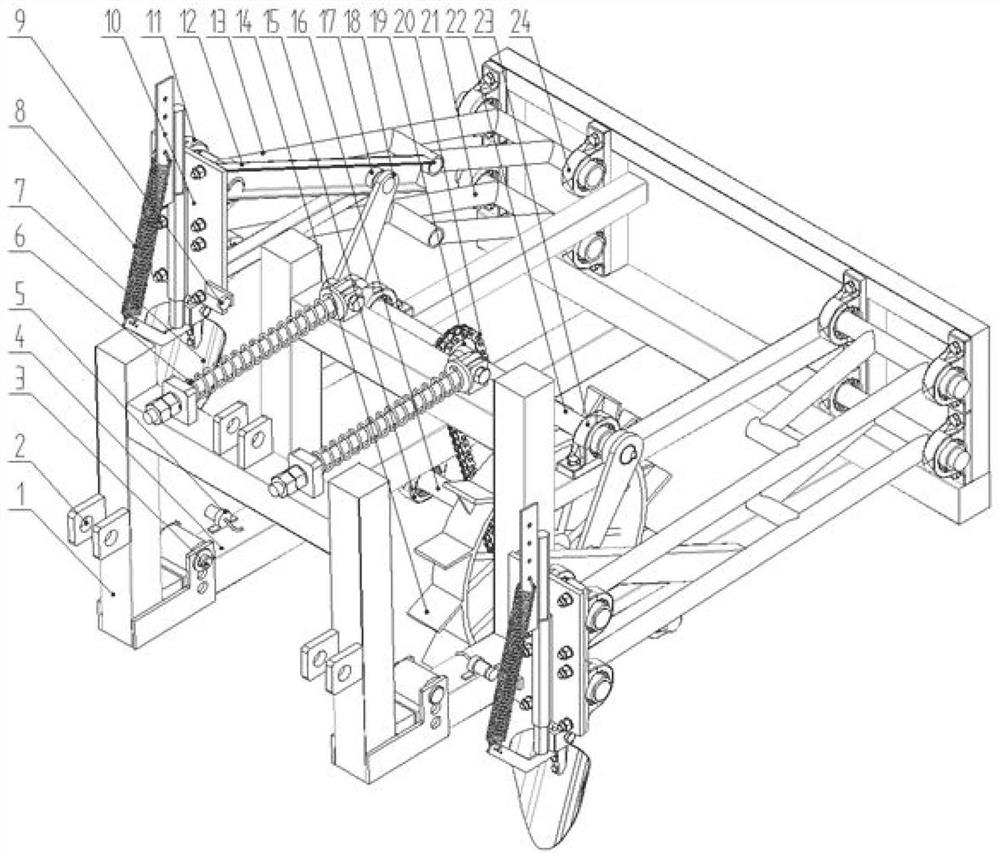

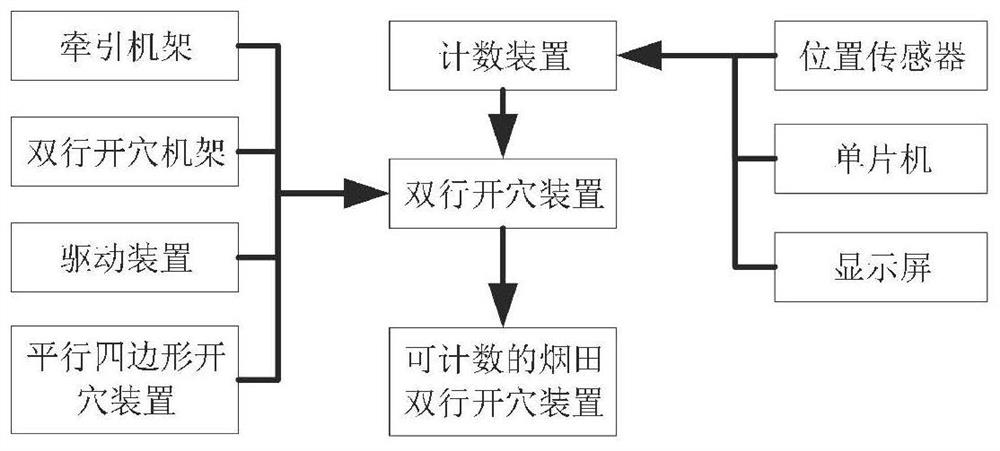

[0031] Such as Figure 1-3 As shown, the present embodiment provides a double-row hole-opening device for tobacco fields, including a traction frame 1, a double-row hole-opening frame 4, a driving device, and a hole-opening device. Tobacco field's double-row acupoint opening device advances; the front end of the double-row acupoint-opening frame 4 is fixedly connected with the traction frame 1, and the driving device is installed on the double-row acupoint-opening frame 4 for driving the acupoint-opening device to open acupoints. Concretely, driving device comprises ground wheel 14 and drive shaft 22, and ground wheel 14 is installed on the dual-row opening frame 4 by the rotation of ground wheel shaft 16, and ground wheel 14 and ground wheel shaft 16 are connected together by key; Drive sprocket is installed, and drive shaft 22 is provided with driven sprocket 19, and drive sprocket and driven sprocket 19 are connected by drive chain 20, forms chain transmission, drives drive...

Embodiment 2

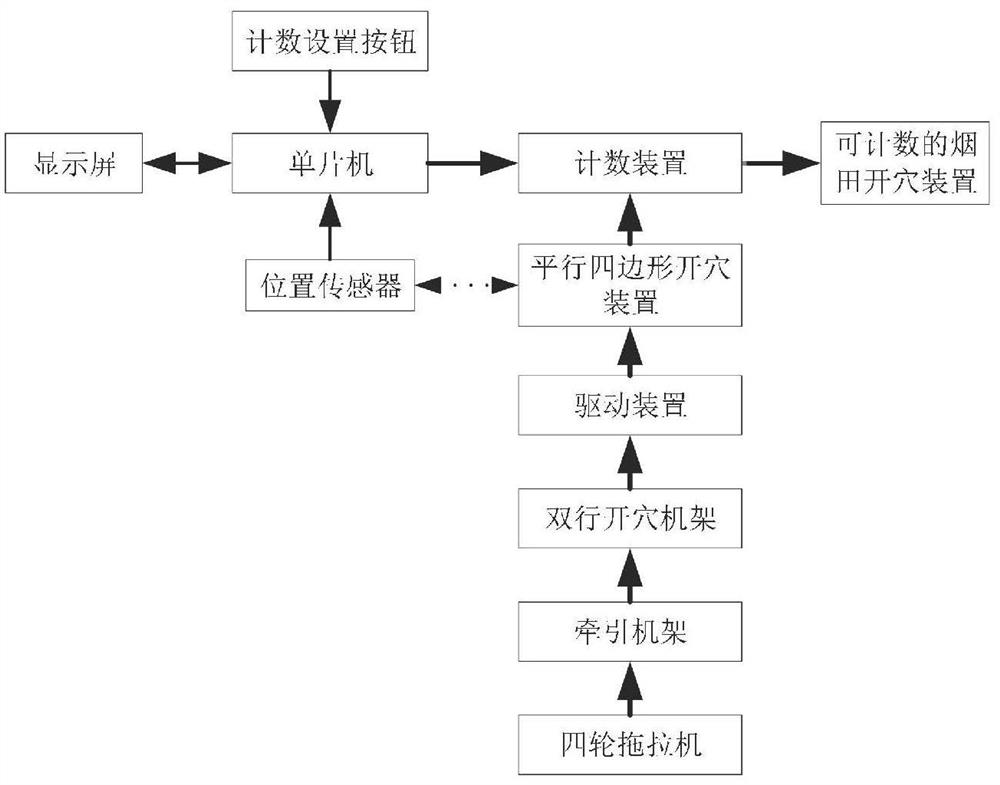

[0041] This embodiment is an improvement made on the basis of Embodiment 1. The improvement is that: in this embodiment, a counting device is also included, and the counting device includes a counting sensor 5, a processor and a display screen, and the holes are opened in two rows. The frame 4 is provided with a counting sensor 5 near the traction frame 1, the counting sensor 5 is connected with a processor, and the processor is connected with the display screen. Specifically, the processor adopts STC8A8K64S4A12 single-chip microcomputer, and the software adopts Keil C for programming; counting workflow: (1) counting sensor 5 detects the number of times of punching acupuncture points; (2) single-chip microcomputer receives, processes and sends data; (3) OLED display screen displays counting ;(4) After counting, press the reset button to reset.

[0042] When the double-row opening device of the entire tobacco field advances, the two working shovels 7 move up and down alternatel...

Embodiment 3

[0045] This embodiment is an improvement made on the basis of Embodiment 1. The improvement is that in this embodiment, the traction device is a four-wheel tractor, and the tractor is also provided with a ridging device, and the traction frame 1 is hooked on On the ridging device; wherein, the ridging device is an existing device, which is selected according to actual work needs.

[0046] In this embodiment, after the two-row hole-opening device of the tobacco field is hooked to the ridging device, the combined operation of ridging and hole-opening can be performed, and the reliability and operation quality of ridging and hole-opening are better.

[0047] The invention has the advantages of high efficiency, accurate hole punching, accurate record of hole number, high operation efficiency and quality, reasonable design, easy promotion, and can better solve the problems of high labor intensity, low efficiency, size of hole opening, Inaccurate acupoint spacing, counting the numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com