Cotton boll combine harvester

A technology for combine harvesters and cotton bolls, which is applied to harvesters, picking machines, agricultural machinery and tools, etc. It can solve the problems of lack of high-efficiency cotton boll combined operation tools, low operating process efficiency, and long operating procedures, so as to reduce land entry The effect of reducing the number of times, reducing work tension, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

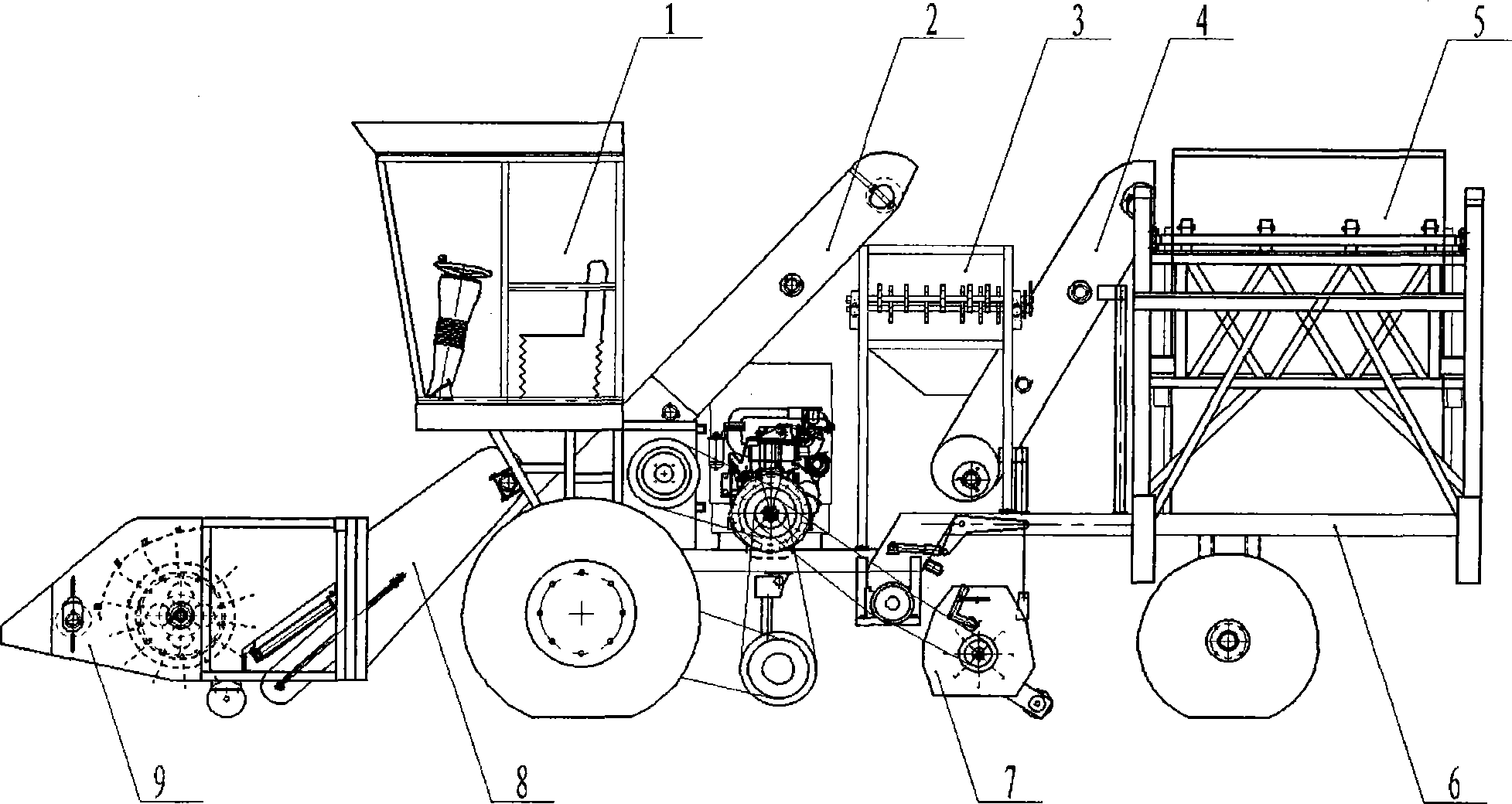

[0020] Such as figure 1 As shown, an embodiment of a cotton boll combine harvester includes a frame 6, a picking device 9, a power manipulation device 1, a primary conveying device 2, a secondary conveying device 4, a separating device 3, a lifting bin 5, a cotton stalk The field returning device 7; the picking device 9 is located at the front end of the frame 6, and is connected with the frame 6 through a bridge 8. There is a separation device 3 above the middle part of the frame 6, and a The first-stage conveying device 2 is equipped with a lifting material box 5 at the rear of the frame 6, and a secondary conveying device 4 is installed between the separation device 3 and the lifting material box 5, and a cotton stalk returning to the field is installed under the middle of the frame 6. device7.

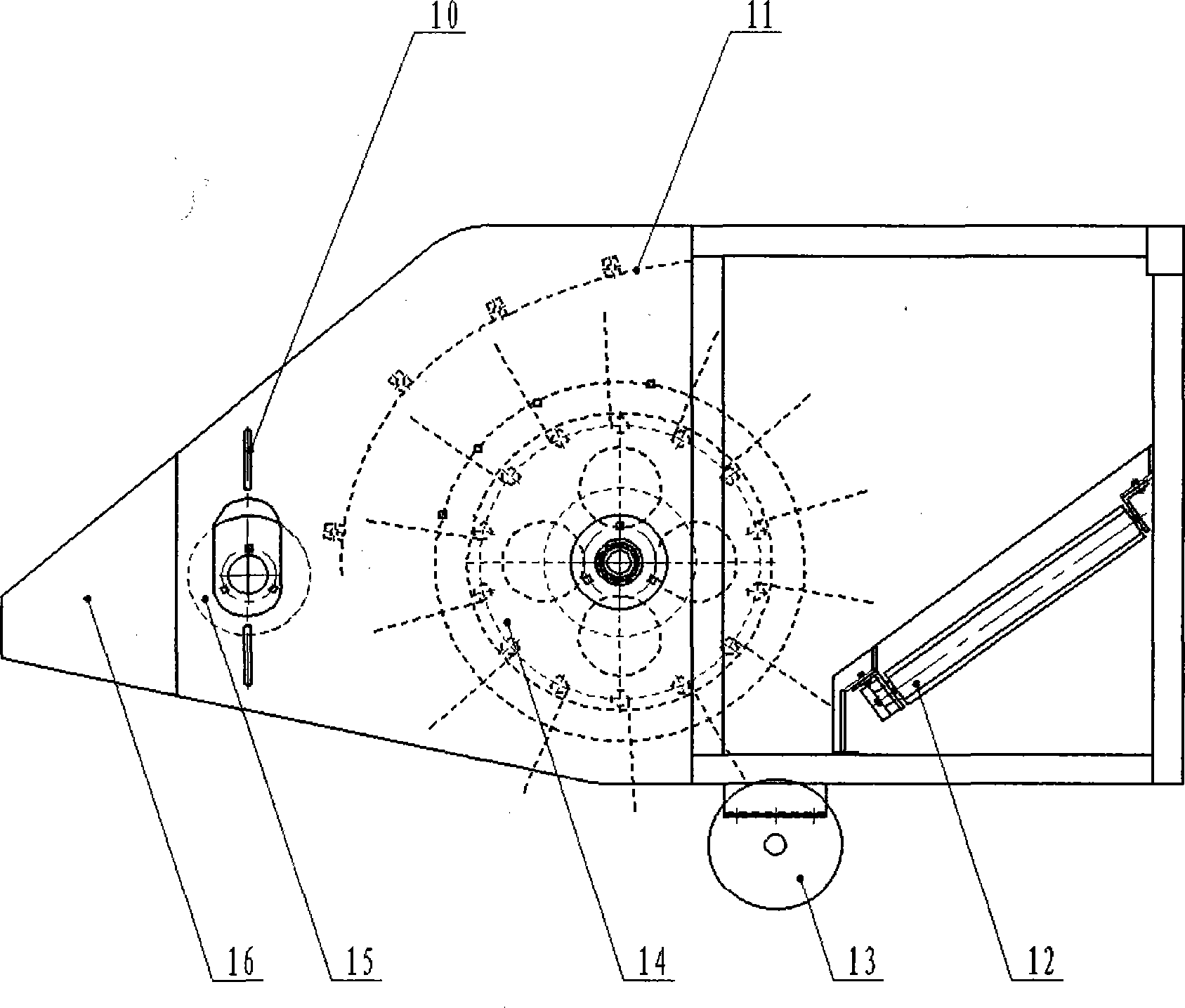

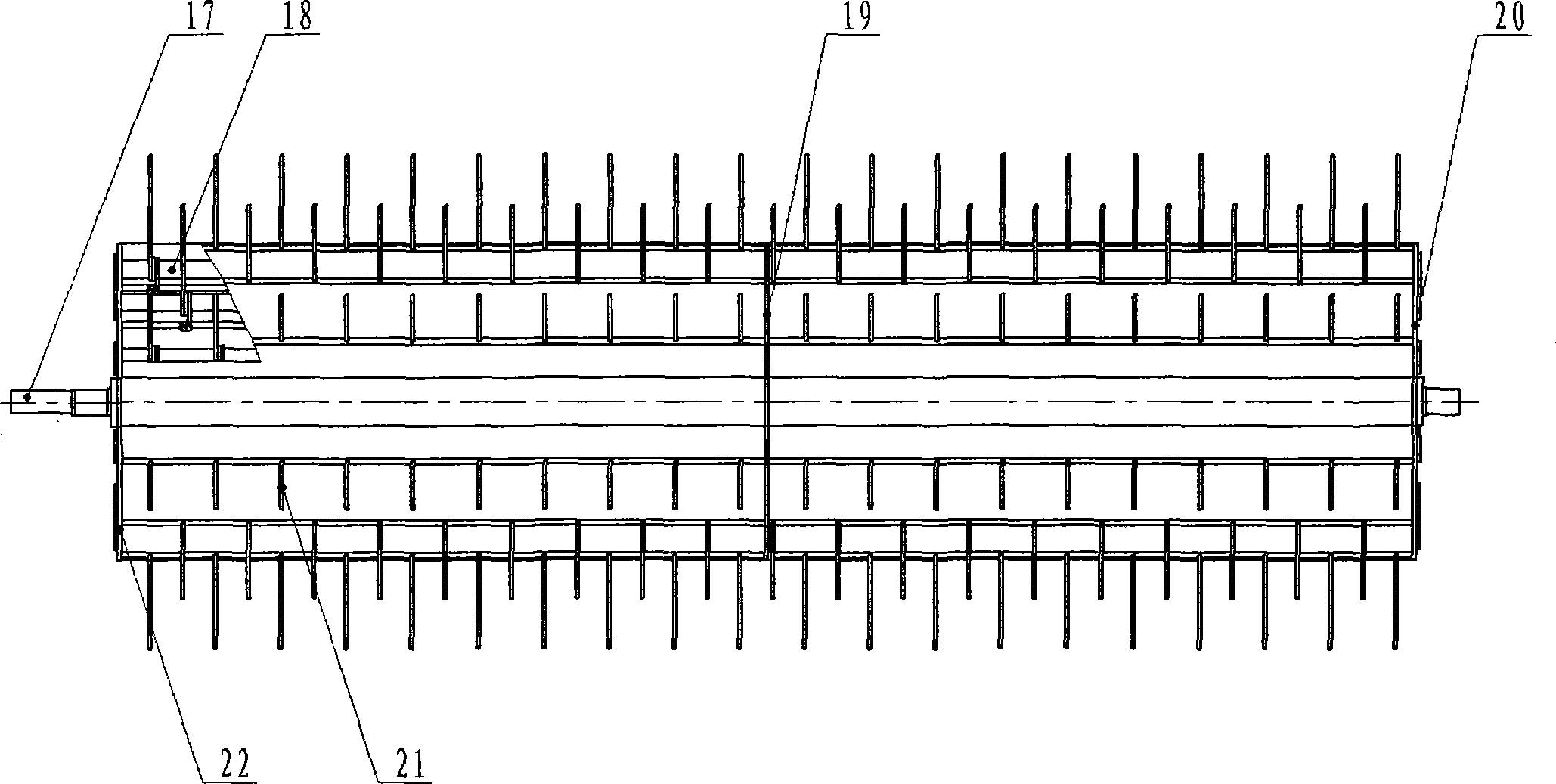

[0021] Such as figure 1 , figure 2 As shown, the picking device 9 includes a horizontal conveying device 12, a drum 14, a grain-holding wheel 15, a depth-limiting wheel 13, a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com