Wide-row flat planting protective tillage planting method for maizes

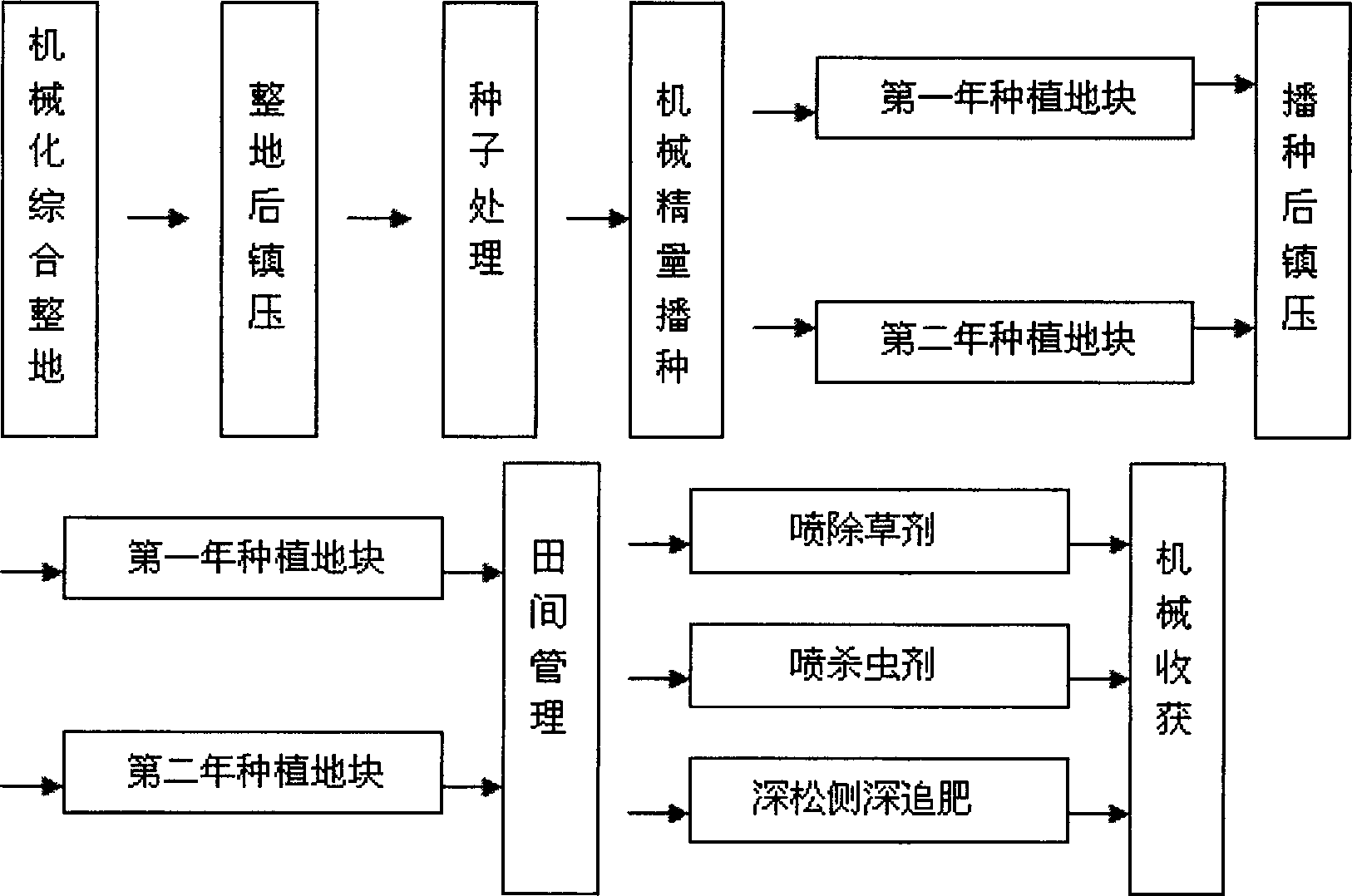

A planting method and protective technology, which is applied in the field of corn wide-row parallel cropping and protective tillage, can solve the problem that high-power tractors cannot implement deep loosening and deep fertilization operations, spray herbicide operations, and cannot adapt to the rapid increase in the number of high-power tractors. trends, the inability to implement inter-row deep loosening and deep fertilization operations in summer, etc., to achieve the effects of sustainable agricultural development, liberating rural labor force, and realizing the combination of land planting and breeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In the first year of the technical test and demonstration of the present invention, the implementation area was 30,000 mu, and the implementation site was 10,000 mu in Central Bu Village, Xiaochengzi Town, Lishu County, Jilin Province; 9,000 mu in Nangangzi Village, Jinshan Township; Jiaba Village is 4,000 mu; Wanfa Town Changsheng Village is 7,000 mu.

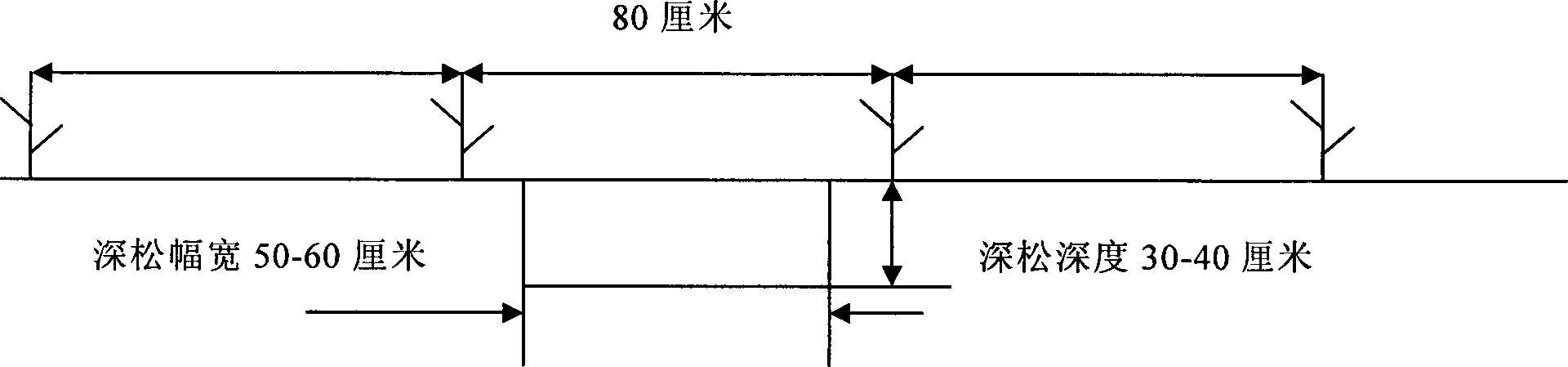

[0044] Soil preparation: work time from April 10th to April 25th, 2008. In the first year of land preparation, since the previous crops were cultivated in a uniform ridge of 60 cm, stubble removal and rotary tillage were required to level the land. Use the Deere 8241 tractor to match the SGTB-190 comprehensive soil preparation machine (remove the ridging parts) to carry out the land preparation operation, the plowing depth is 15cm, and the stubble length is ≤10cm. After the land preparation, when the surface soil has a dry soil layer of about 1cm, Use the Deere 8241 tractor equipped with PY-3.4 41 disc harrows, wooden ...

Embodiment 2

[0056] 2009 is the second year of the test and demonstration of the present invention. The implementation area was 50,000 mu in that year, and 20,000 mu was newly added. Implementation location: 12,000 mu in Central Bu Village, Xiaochengzi Town; 10,000 Mu in Nangangzi Village, Jinshan Township; 5,000 Mu in Qianjiaba Village, Lamadian Town; 8,000 Mu in Changsheng Village, Wanfa Town; 10,000 mu; Sankeshu Village, Sikeshu Township, 8,000 mu, two new townships.

[0057] Soil preparation: After the second year of planting, there is no need to prepare the land, and direct no-tillage sowing.

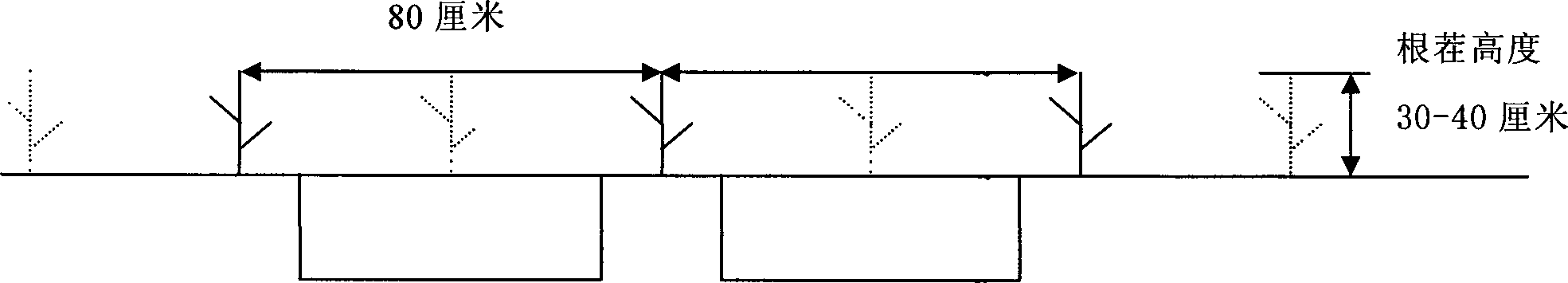

[0058] Sowing: Sowing time from April 28th to May 8th, such as image 3 As shown, for sowing after the second year, use Benye 484 tractor to support the 2BMF-3 no-tillage seeder developed by this site to sow on the center line of the two rows covered by high stubble in the previous year, and the technical requirements are the same as the previous one. year.

[0059] Repression after sowing: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com