Mechanism for mixing nitrogen fertilizer and phosphorus in ratio and applying mixed fertilizer

A technology of proportional mixing and fertilizing mechanism, applied in the field of agricultural machinery research, can solve the problems of unstable operation quality, increased resistance of equipment, unstable center of gravity, etc., to save manpower and energy, reduce ditching resistance, and improve operation. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

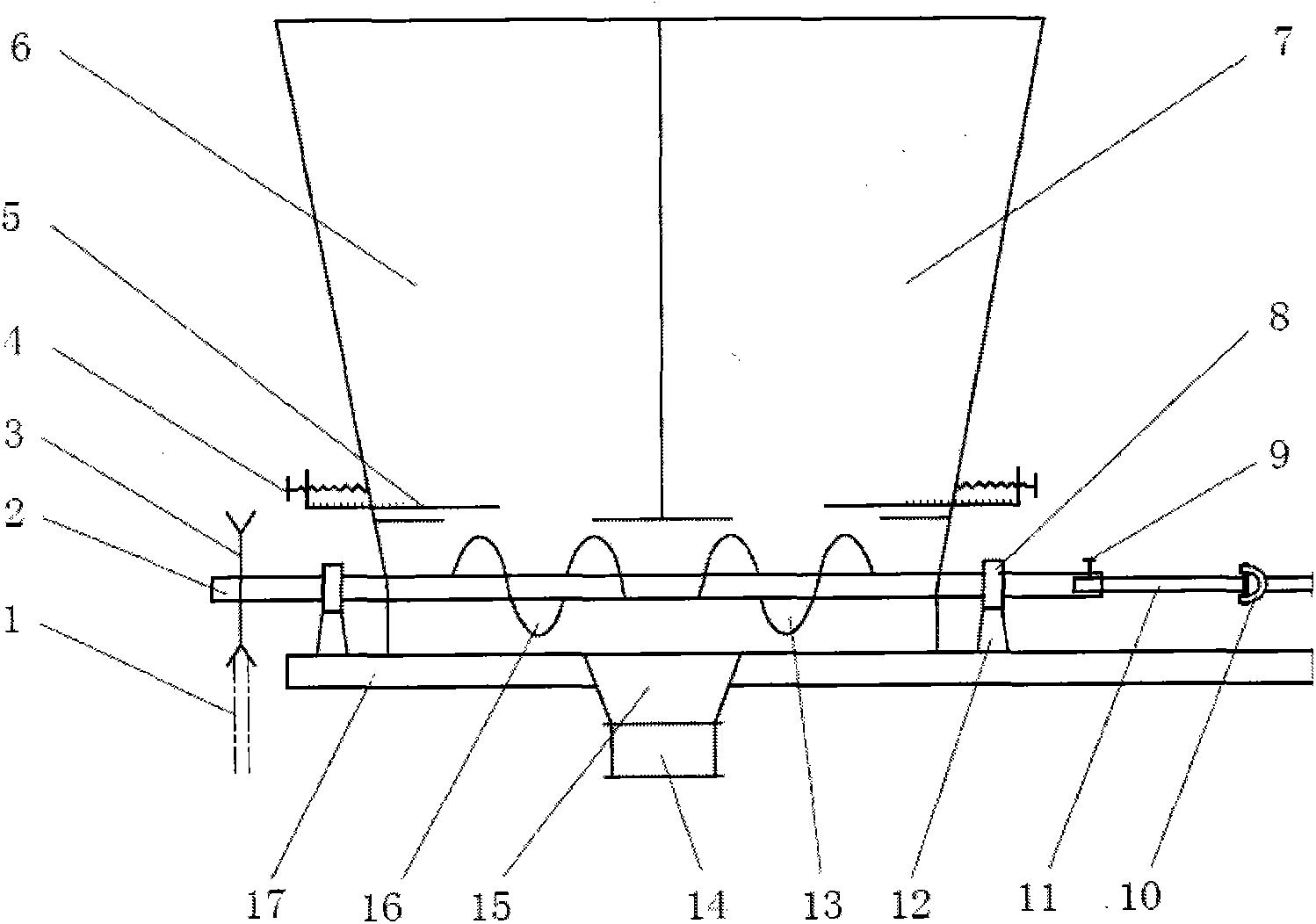

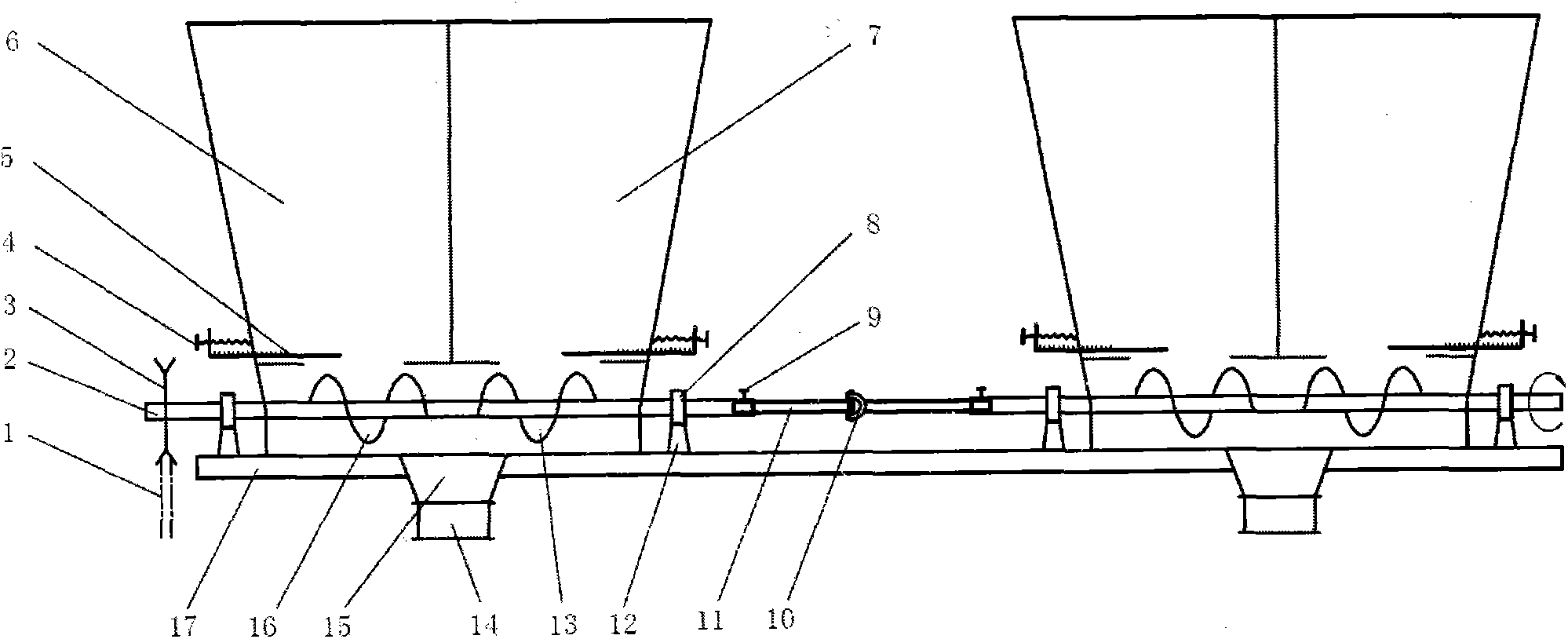

[0015] Below in conjunction with accompanying drawing, the present invention will be further described:

[0016] figure 1 It is a schematic diagram of a nitrogen-phosphorus fertilizer ratio mixed fertilizer discharge mechanism of the present invention, including a frame 17, a main shaft 2, a nitrogen fertilizer box 6, a phosphate fertilizer box 7, a left-handed screw 13, a right-handed screw 16, a fertilizer control panel 5, and a mixed fertilizer pipe Joint 14, the main shaft 2 is installed on the frame 17 through the bearing 8 and the bearing block 12, the nitrogen fertilizer box 6 and the phosphate fertilizer box 7 are fixedly installed on the frame 17, and the left-handed helix 13 and the right-handed helix 16 are welded and fixed On the main shaft 2, the collector 15 and the mixed fertilizer pipe joint are installed below the frame 17;

[0017] Sprocket wheel 3 is installed on described main shaft 2, and fertilizer amount control board 5 and adjusting screw 4 are install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com