Method and apparatus for cooling an electronic device

a technology for electronic devices and cooling devices, applied in lighting and heating apparatus, indirect heat exchangers, semiconductor/solid-state device details, etc., can solve the problems of inapplicability to standard semiconductor packaging techniques, the ultimate performance of air-cooled heat sinks is limited by available space, and the length of fins is increased

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

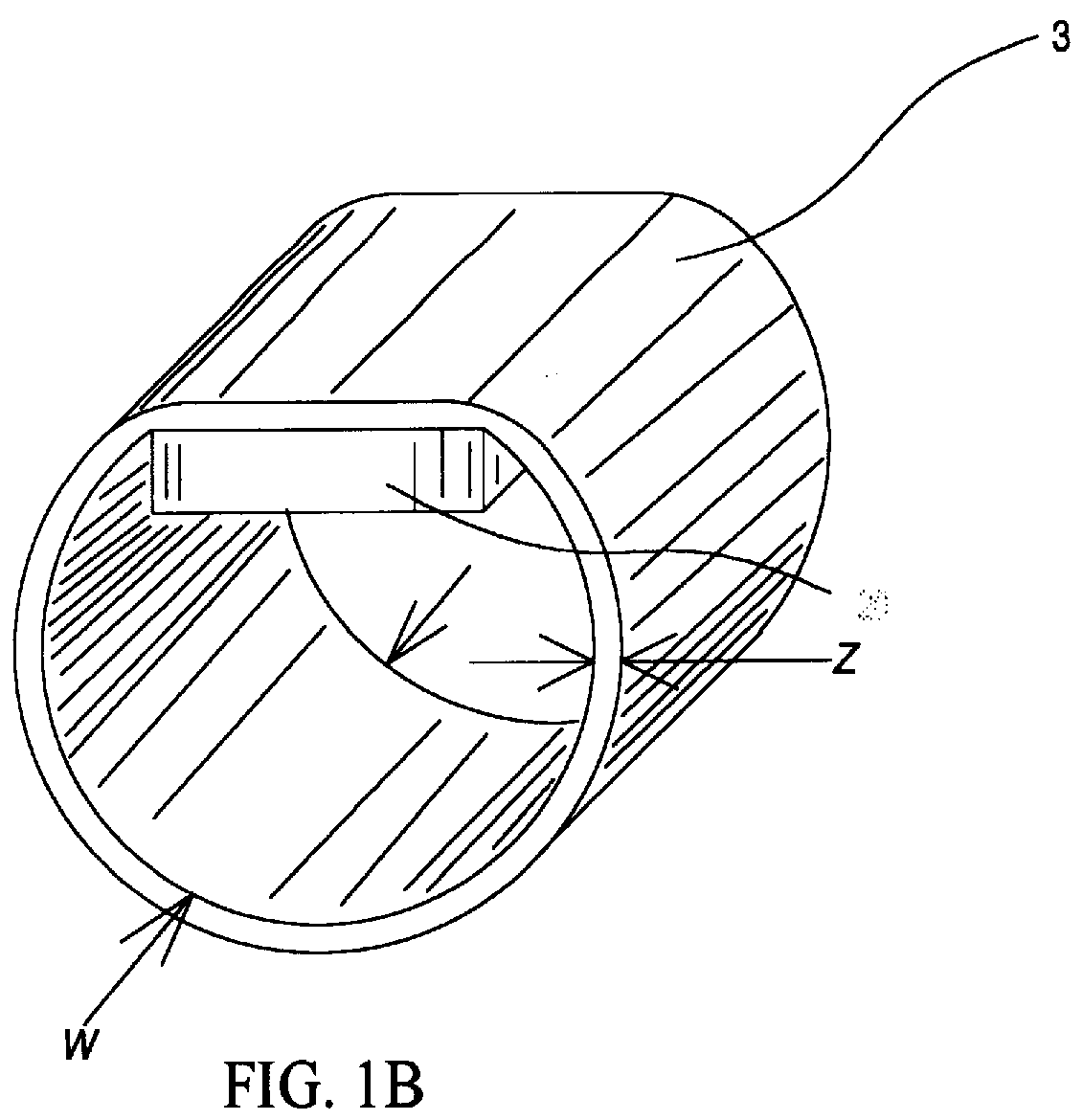

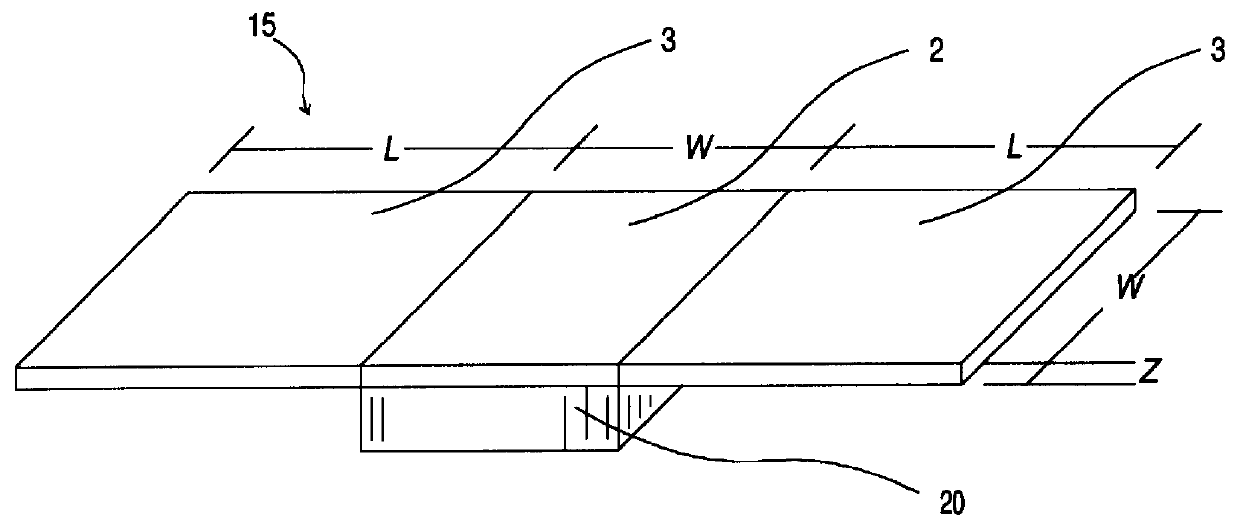

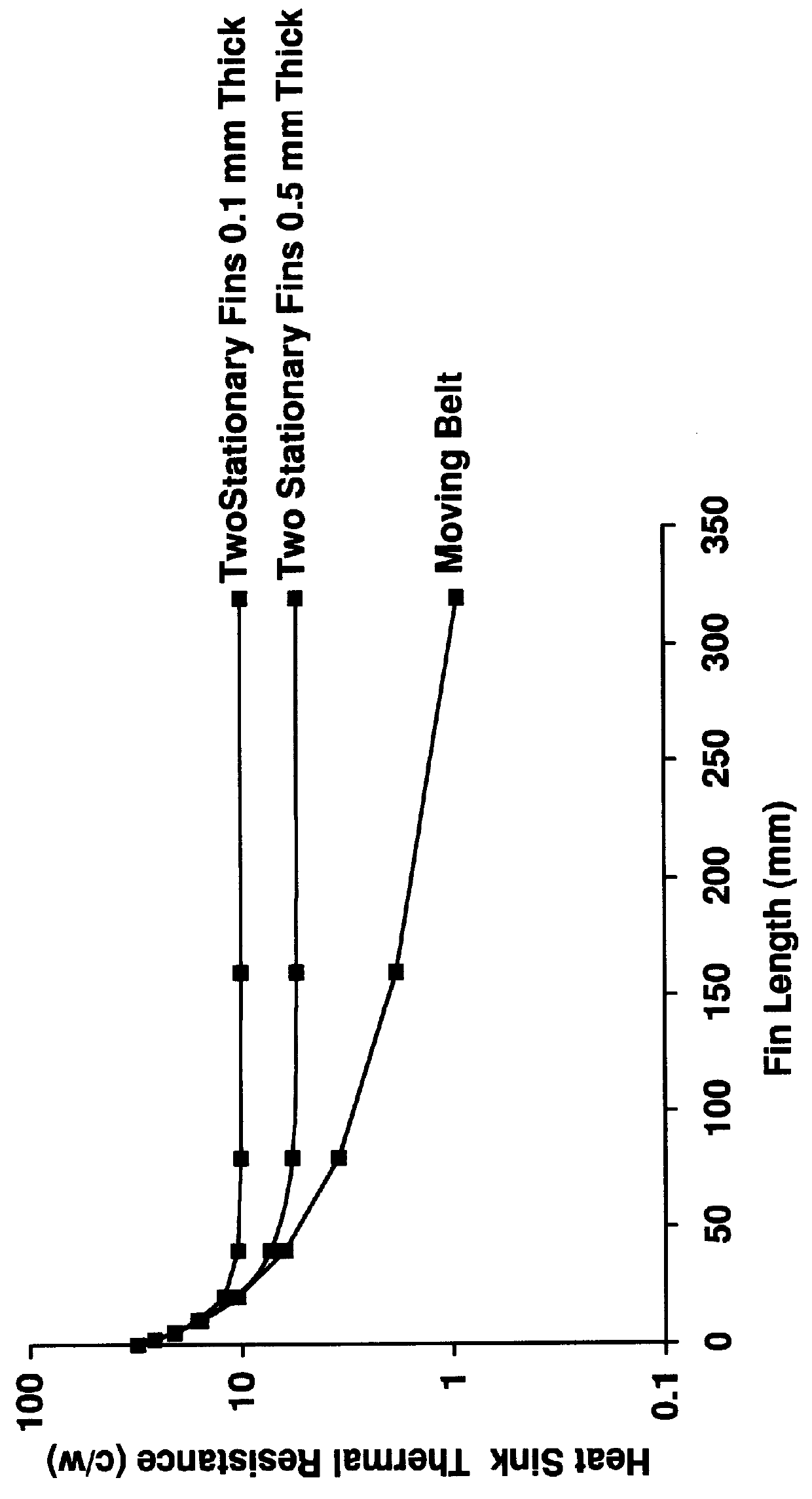

The advantage of the current invention can be realized by comparing its thermal performance to a conventional finned air colled electronic module heatsink. It will be immediately recognized by one skilled in the art that the invention is equally applicable to use with other heat transfer fluids such as liquids and gasses, other thermal control problems in other industries. The predominate heat transfer mechanism does not need to be limited to convection and could include contact and radiation heat transfer from the moving fin. Attention is directed to FIG. 1A heat sink 15 which is in contact with an electronic module 20, the heat sink has a square isothermal base 2 of dimension "w" which is typically about the same size as the electronic devices, such as semiconductor modules. Space above the module is limited so fins 3 are added to opposite edges of the base. The thermal performance of this heat sink can be estimated by making some simplifying assumptions. There are two fins 3 of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com