Rotary Heat Exchanger Device

a heat exchanger and rotary technology, applied in lighting and heating apparatus, ventilation systems, heating types, etc., can solve the problems of high assembly cost and coupling no longer working reliably, and achieve the effects of saving complicated calibration, reducing pressure loss, and high heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

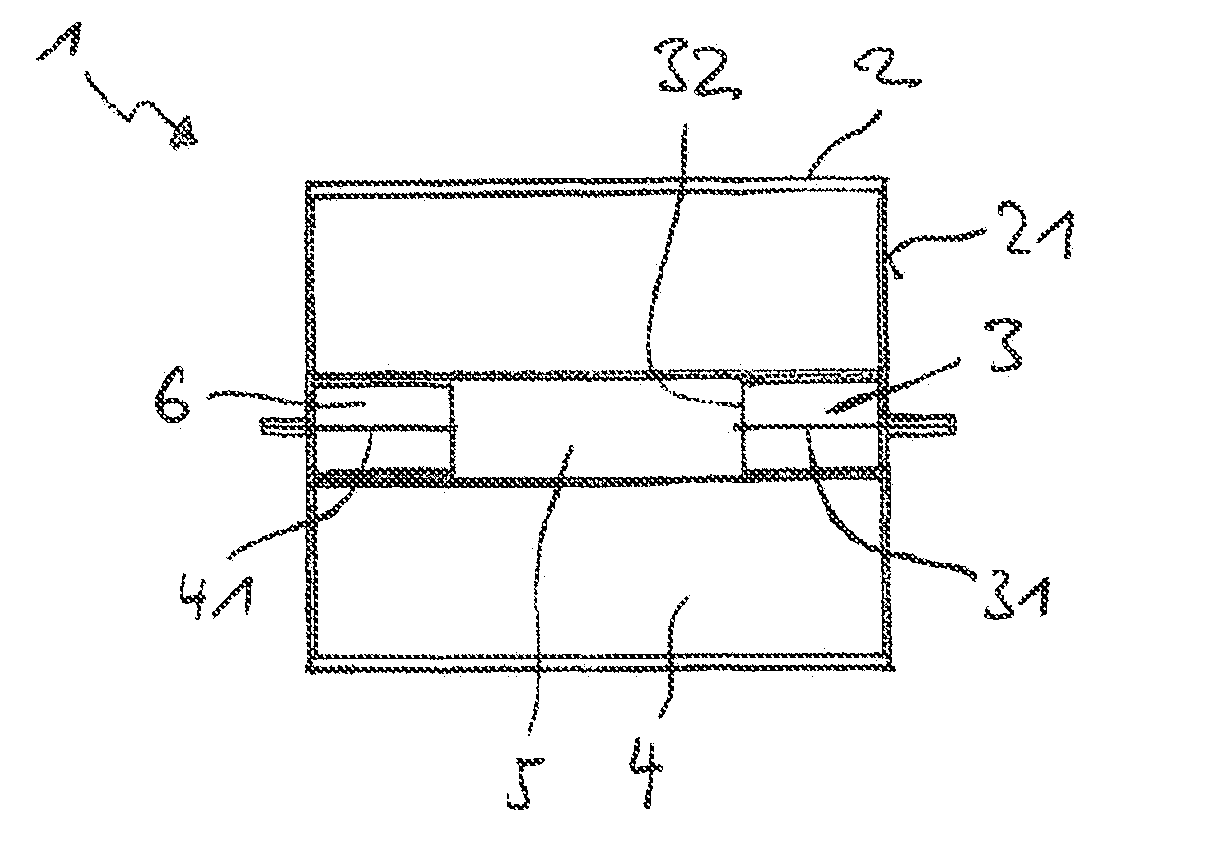

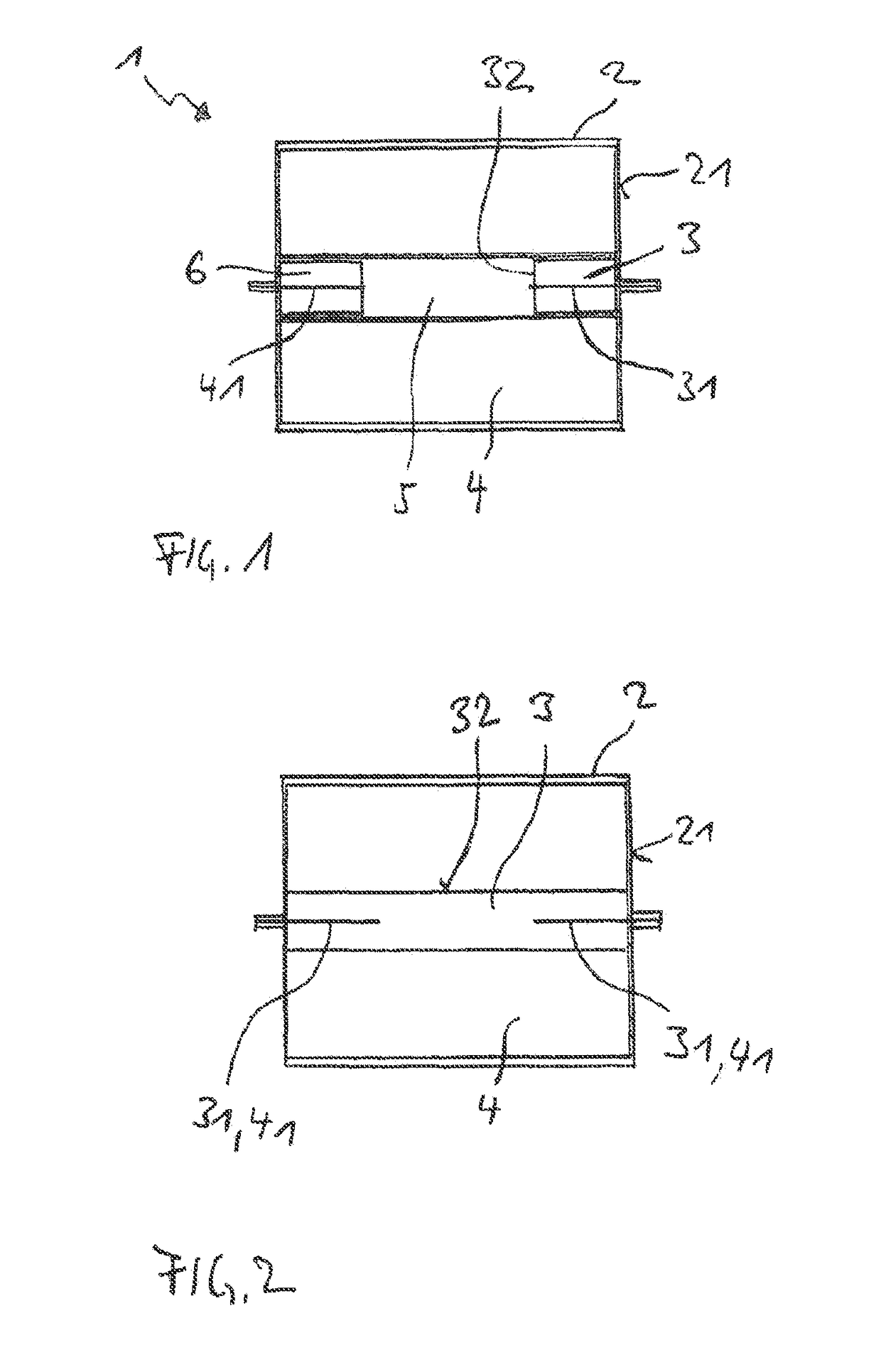

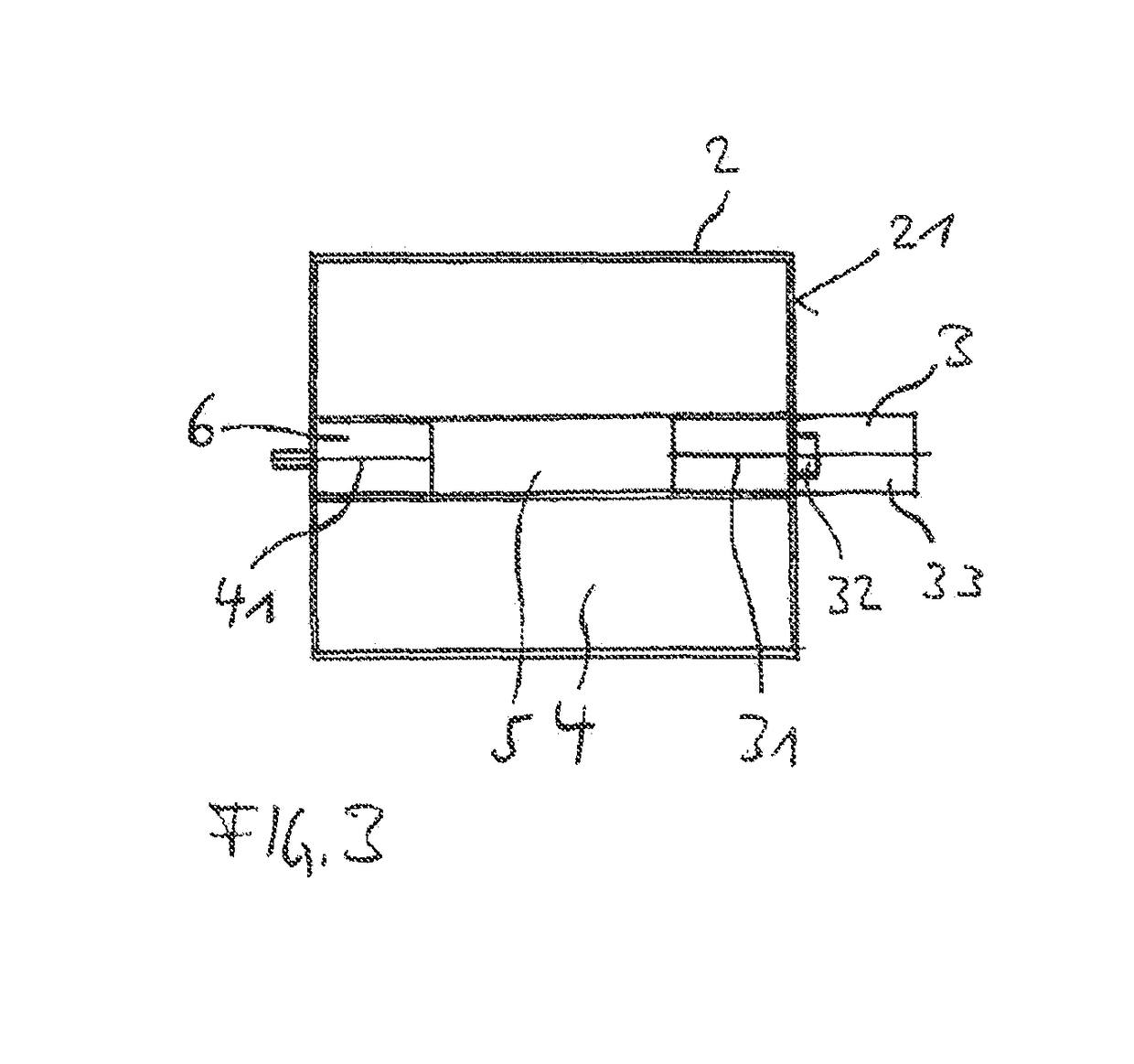

[0018]The FIGS. 1 to 3 show in each case one exemplary embodiment of a rotary heat exchanger device 1 having, for example, a cubic housing 2, for example, made of sheet metal or plastic, an electric drive motor 3 and a cylindrical rotary heat exchanger 4. The housing 2 comprises openings (not shown) at the sides for air intake into and air outlet out of the rotary heat exchanger 4.

[0019]In the exemplary embodiments in accordance with FIGS. 1 and 2, the drive motor 3 is arranged within the rotary heat exchanger 4 in such a way that the axis of rotation of the rotor 32 of the drive motor 3, i.e., the motor axis of rotation 31, is coaxial with an axis of rotation of the rotary heat exchanger 4, hereafter heat exchanger axis of rotation 41.

[0020]The rotor 32 is rigidly connected to the rotary heat exchanger 4, for example, by means of a toothing system or a screw fitting between rotary heat exchanger 4 and rotor 32.

[0021]A stator (not shown) of the drive motor 3 is rigidly connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com