Motorized valve

A technology of electric valves and valve seats, applied in the field of control valves, can solve problems such as insufficient flow area of valve chambers, and achieve the effects of avoiding sudden changes in pressure, preventing refrigerant noise, and preventing sudden changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

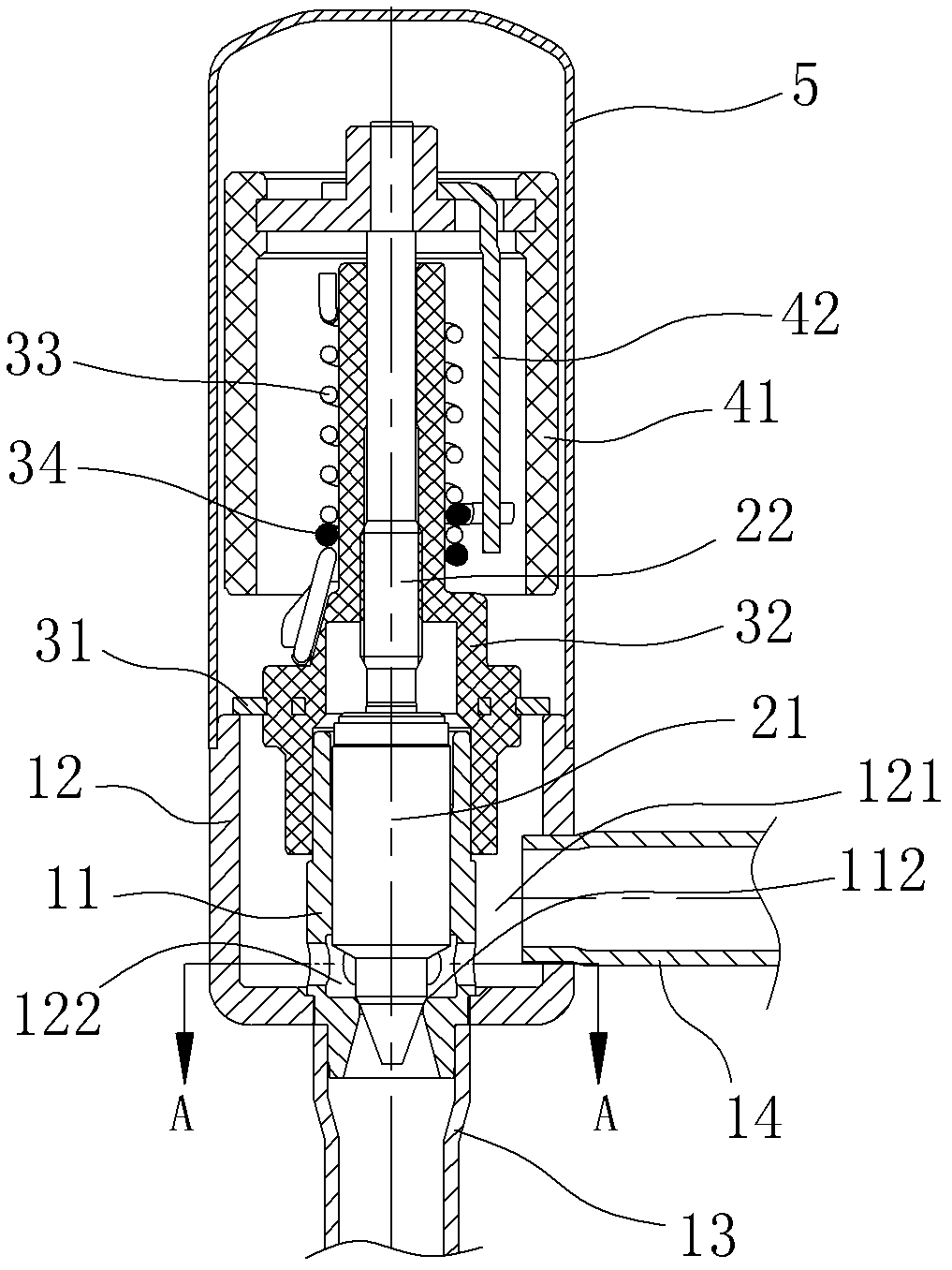

[0051] Please refer to figure 1 , figure 1 It is a structural schematic diagram of a specific embodiment of an electric valve provided by the present invention.

[0052] The electric valve provided by the invention includes a valve seat assembly, a nut assembly, a valve needle screw assembly and a magnetic rotor assembly.

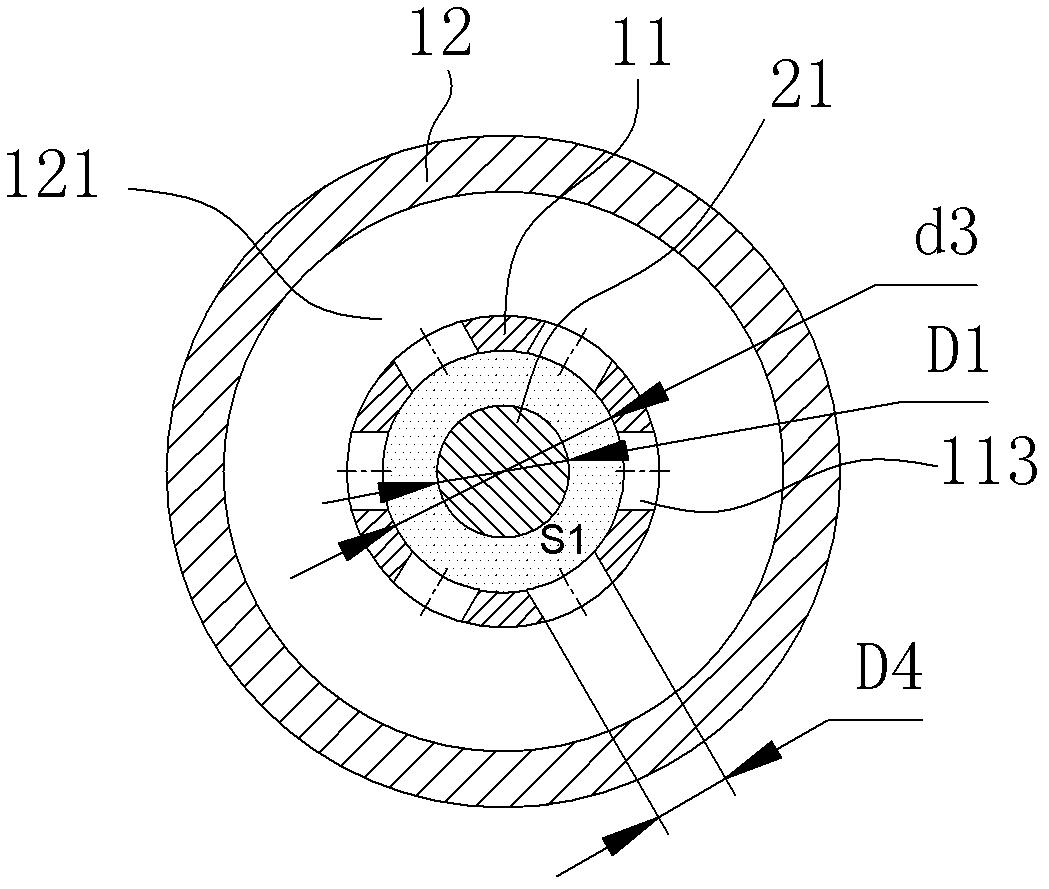

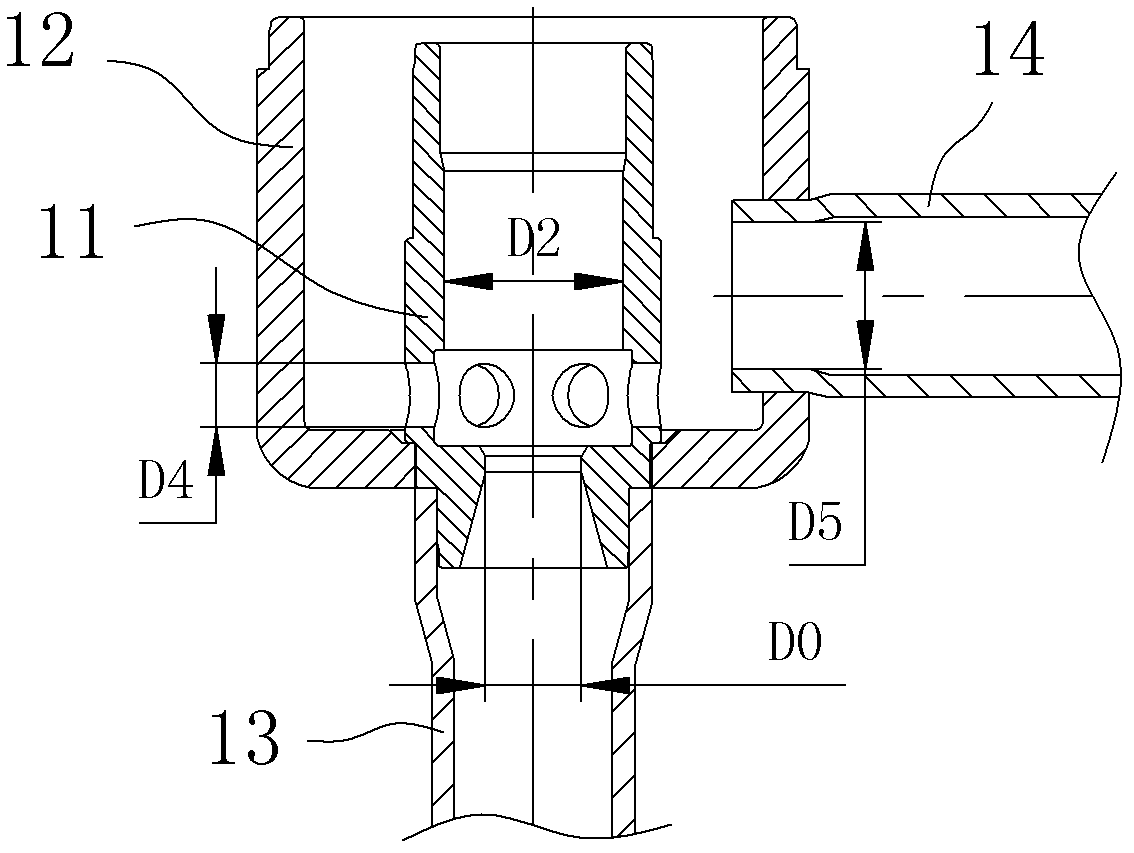

[0053] The valve seat assembly includes a valve core seat 11 and a valve seat 12 . The valve seat 12 is a substantially cylindrical structure with a matching hole on the bottom of the valve core seat, and a first valve cavity 121 is formed inside it. In this embodiment, the valve seat assembly further includes a first connecting pipe 13 and a second connecting pipe 14 . The valve core seat 11, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com