Environment-friendly type refrigerant

A refrigerant and environmentally friendly technology, applied in sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve the problems of high GWP value, high cost of use, high price, etc., achieve good environmental performance and improve energy efficiency ratio, the effect of reducing the amount of filling

Inactive Publication Date: 2008-04-09

ZHEJIANG LANTIAN ENVIRONMENTAL PROTECTION HI TECH

View PDF11 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] 1). Invention patents with publication numbers CN1055300C and CN1244663C, using a ternary mixture of HFC-32, HFC-125 and HFC-152a as a substitute for HCFC-22, which has similar thermal properties to HCFC-22, but has not been resolved Under long-term operation, the compatibility of the alternative working fluid with the HCFC-22 compressor and lubricating oil

[0006] 2). The invention patent with publication number CN1412266A uses a mixture of HFC-32, HFC-134a and HFC-143a to replace HCFC-22; the invention patent with publication number CN1136065A uses a mixture of HFC-32, HFC-125 and HFC-227ea Replace HCFC-22; CN1189525A uses a mixture of HFC-32, HFC-134a and HFC-227ea to replace HCFC-22, but there is a problem of high GWP value

[0007] 3). The invention patent with publication number CN1173525A uses a mixture of HC-290, HC-600a and TS flame retardant to replace HCFC-22; the invention patent with publication number CN1255502C uses HC-1270, FC-13I1 and HC-170 The mixture replaces HCFC-22. This type of mixture mainly uses hydrocarbons and their compositions, which has hidden dangers of haze effect and may cause new environmental problems.

[0008] 4). The invention patent with publication number CN1189525A also uses a mixture of HFC-32, HFC-134a, HFC-152a and FC-13I1 to replace HCFC-22; the invention patent with publication number CN1255502C uses FC-13I1, HFC-134a and The mixture of CO2 replaces HCFC-22. This type of mixture uses FC-13I1, which has relatively good environmental performance and thermal performance. However, because iodine (I) cannot be synthesized artificially, FC-13I1 is expensive and the cost of use is extremely high. conducive to widespread use

[0009] 5). The invention patent with publication number CN1780892A uses a mixture of HFC-161, HFC-32 and HFC-125 to replace HCFC-22, but this substitute cannot use HCFC-22 compressors and mineral oil, and must use R407C or R410A compressors and ester oils have high replacement costs and are not suitable for direct replacement in HCFC-22 systems

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

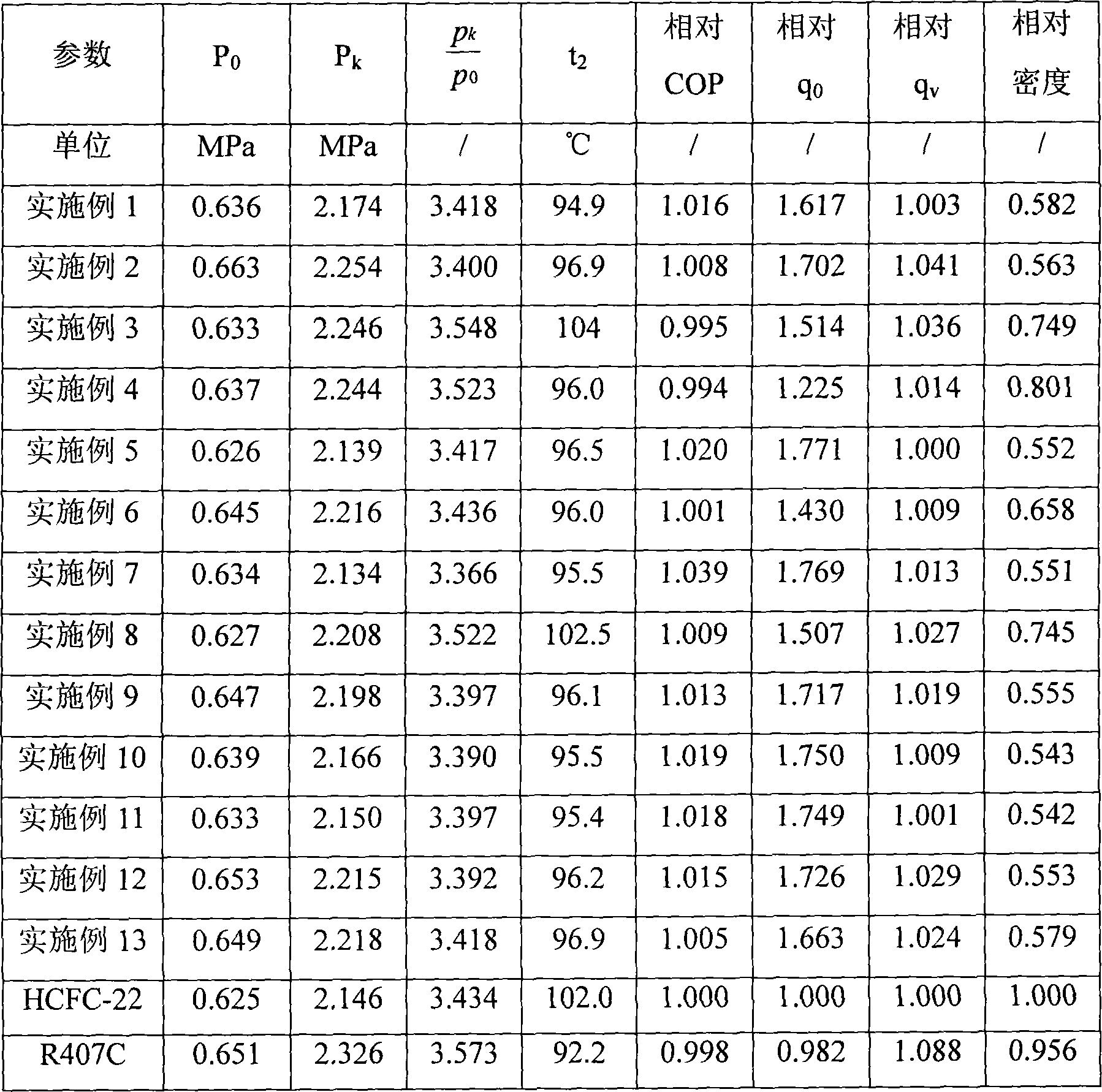

[0035] Physically mix HFC-161, HFC-125, HFC-32, and HC-600 in a liquid phase at a mass percentage of 71:10:14:5.

Embodiment 2

[0037] Physically mix HFC-161, HFC-32, and HC-600 in a liquid phase at a mass percentage of 75:20:5.

Embodiment 3

[0039] Physically mix HFC-152a, HFC-32, and HC-600 in a liquid phase at a mass percentage of 45:50:5.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

| critical pressure | aaaaa | aaaaa |

| critical temperature | aaaaa | aaaaa |

Login to View More

Abstract

An environmental-friendly refrigerant, used in equipments such as refrigerators, air-conditions, and heat pumps, etc., is directly in place of the HCFC-22 refrigerant technology field, and consists of components A, B, and C. The component A is one of ethyl fluoride or 1, 1-difluoroethane or the mixture of the two according to any proportion. The component B is Difluoromethane. The component C is one of isobutane, normal butane, propane and propylene or mixture of two or more of the chemicals according to any proportion. The invention overcomes the disadvantages of the prior art of alternative refrigerant and the deficient compatibility between HCFC-22 compressors and lube, as well as the high GWP. The invention provides a refrigerant with good environment performance, the thermal parameters of which is similar to that of HCFC-22. The invention can be used directly in the former system of HCFC-22, as well as the HCFC-22 compressor and lube. The unit volume refrigerating capacity is great while the density is small, thus reducing the mass of using and increasing the energy efficiency ratio, as well as saving resources. The refrigerant can be a long-term substitute of HCFC-22.

Description

technical field [0001] The invention relates to a refrigerant, in particular to an environment-friendly refrigerant used in refrigeration, air-conditioning, heat pumps and other equipment to directly replace HCFC-22 with basically unchanged system, zero atmospheric ozone destruction potential and low greenhouse effect. Background technique [0002] HCFC-22 has become the most widely used refrigerant with the best comprehensive performance in the refrigeration and air-conditioning industry at home and abroad due to its excellent physical, chemical and thermodynamic properties as well as good use safety and economy. However, HCFC-22 has a relatively high GWP (Global Warming Potential) value and ODP (Ozone Depletion Potential) value are not friendly to the environment and are required to be phased out within a time limit. [0003] At present, the most widely used substitutes for HCFC-22 are R410A and R407C, but they each have certain defects, that is, the heat transfer of R407C...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09K5/04

CPCY02P20/10

Inventor 郭智恺郭心正

Owner ZHEJIANG LANTIAN ENVIRONMENTAL PROTECTION HI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com