Thermopile and automobile exhaust waste heat generation and refrigeration device employing same

A technology of thermoelectric power generation and thermopile, which is applied in the field of refrigeration technology and automobile exhaust waste heat power generation, and can solve the conversion efficiency of thermoelectric power generation devices, the space occupied by manufacturing costs, the wide application of thermoelectric thermoelectric power generation and refrigeration technology, and the integration of thermopile thermoelectric modules Low temperature, low thermocouple electromotive force, etc., to eliminate adverse effects, save welding process, and improve thermoelectric conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

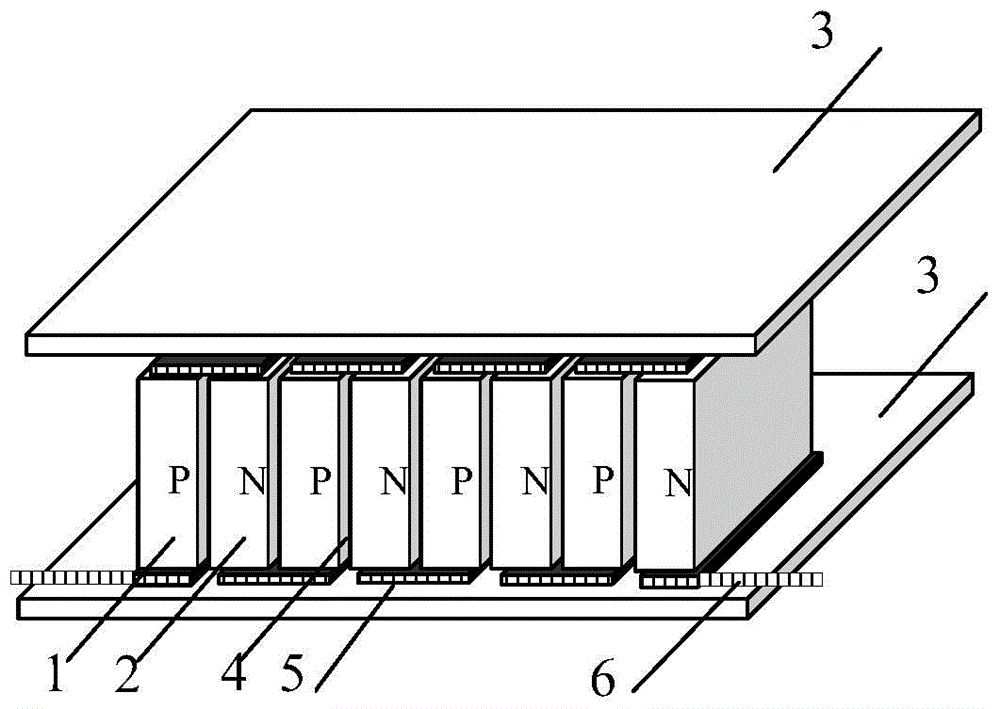

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Such as figure 1 As shown, the interior of the thermopile of the present invention includes a plurality of thermocouples connected in series. Each thermocouple is composed of a P-type thermocouple arm 1 and an N-type thermocouple arm 2, and is packaged in a housing. Type thermocouple arms 1 and N type thermocouple arms 2 are arranged in a staggered order, and are connected by inserting heat-insulating insulating film material 4 between adjacent sides. Each pair of adjacent P-type thermocouple arms 1 and N-type thermocouple arms The upper bottom surface of 2 is connected to form a thermocouple through the thermally conductive electrode material 5, and each thermocouple is sequentially connected to the thermally conductive electrode material 5 through the lower bottom surface of its thermocouple arm to form a series circuit, and the lower bottom su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com