Improved A2O biochemical reaction system and sewage treatment method

A sewage treatment method and biochemical reaction technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

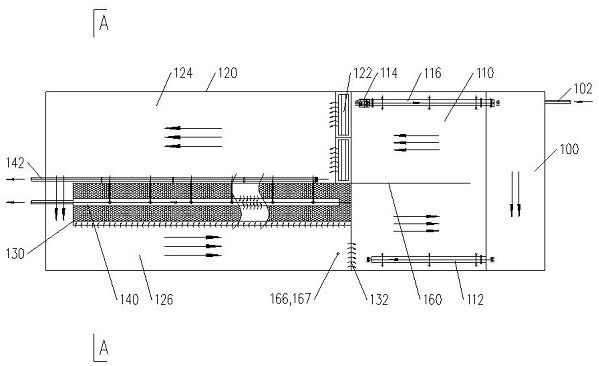

Embodiment Construction

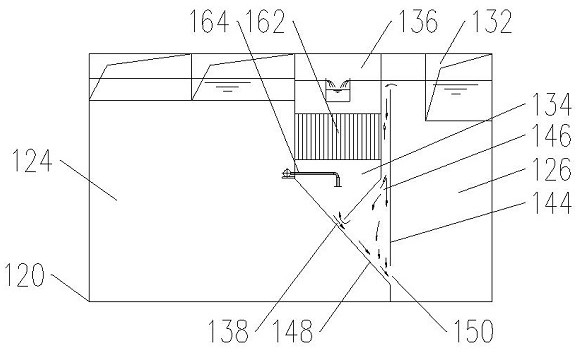

[0047] The second baffle plate 148 is arranged on the bottom of the mud-water separation bin 134, and the second baffle plate 148 is arranged obliquely downwards and extends to the below of the first baffle plate 144, and muddy water is formed between the first baffle plate 144 and the second baffle plate 148. The outlet 150 and the water outlet end of the fourth flow channel 146 are connected to the muddy water inlet 138 and the muddy water outlet 150 .

[0048] In some embodiments, the second baffle 148 is an inclined pool bottom, and the pool bottom is formed with an inclined surface.

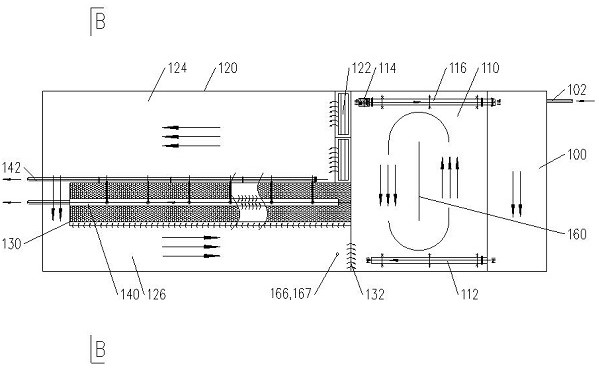

[0049] When the improved A2O biochemical reaction system provided according to the embodiments of the present invention works:

[0050] The mixed solution after the anaerobic phosphorus release reaction enters the head end of the anoxic zone 110 under the action of the first overflow channel 112, and the mixed solution after the anaerobic phosphorus release reaction is uniform with the nitri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com