Sewage treatment method using active sludge-biological filtering pond revere flow and integral device

A sewage treatment device and activated sludge technology, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve difficult operation control and management, increase energy consumption, aerobic section Continuous aeration has high energy consumption and other problems, and achieves good organic matter and suspended matter removal capacity, water and energy saving, and good treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

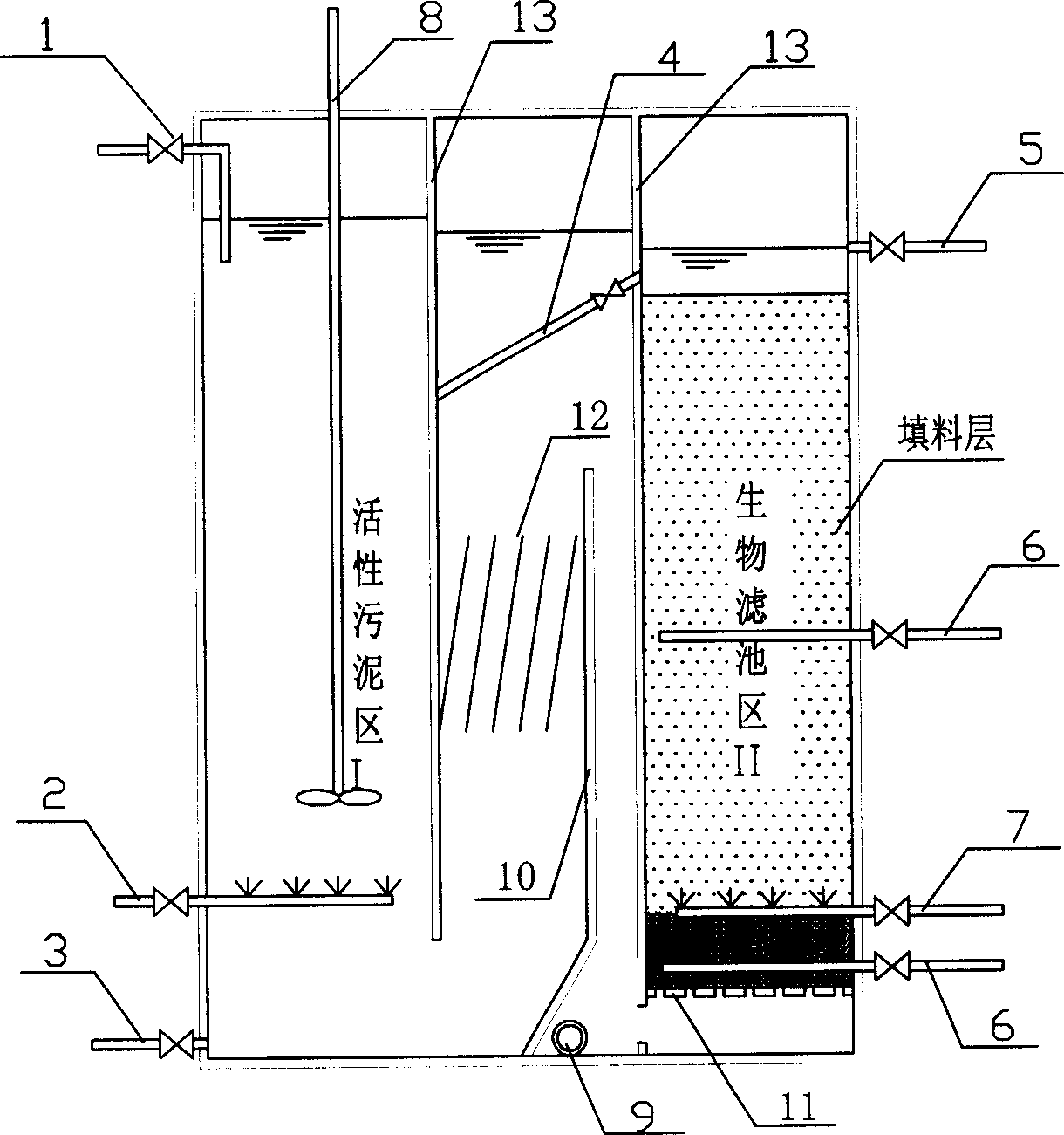

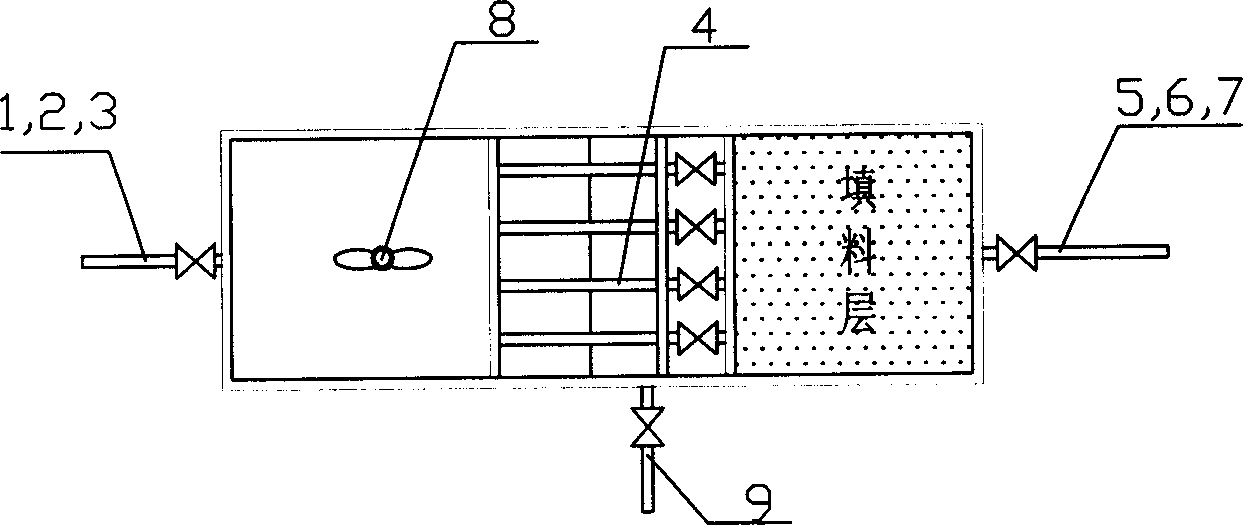

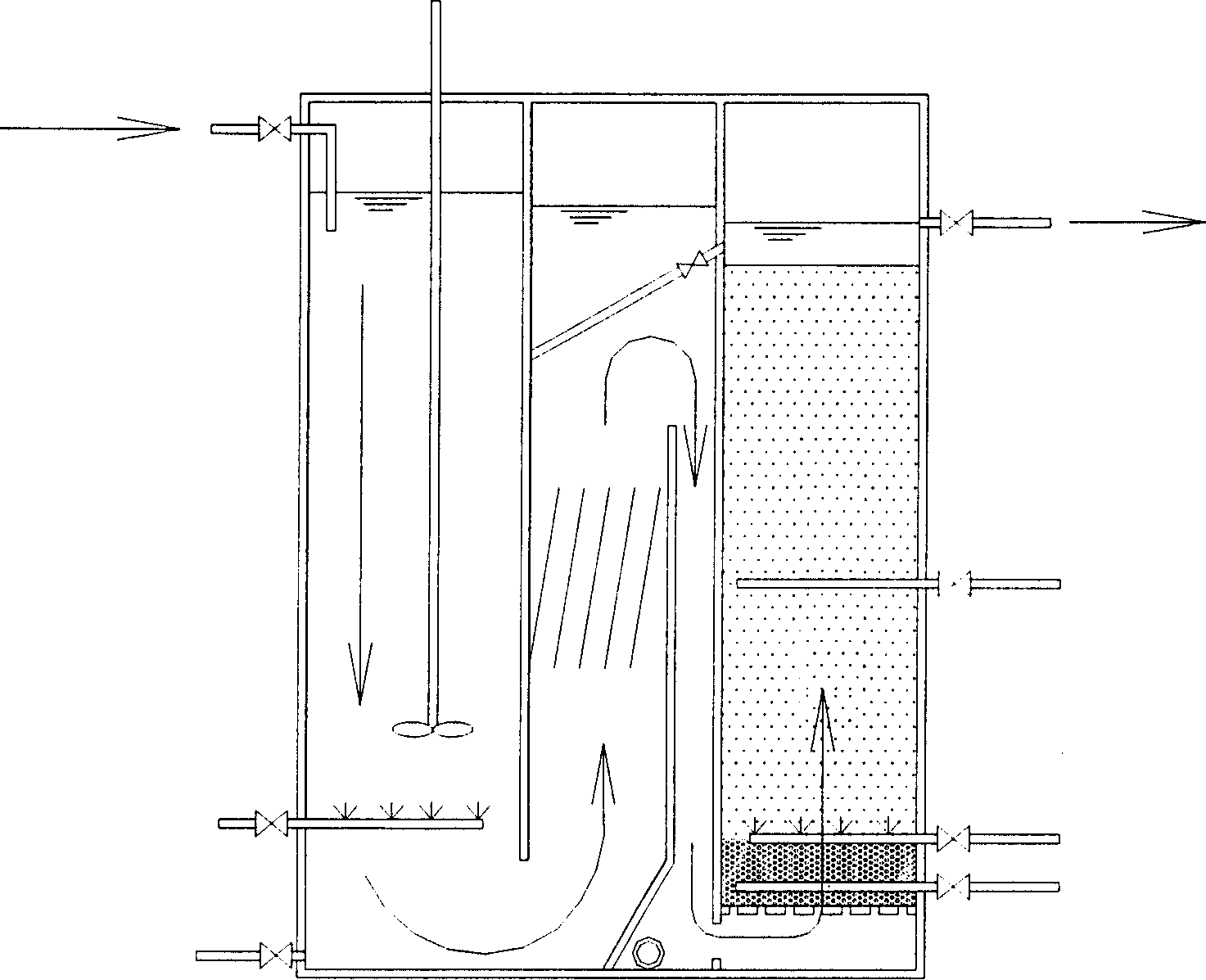

[0026] Embodiment 1: see figure 1 , 2 , the activated sludge-biological filter internal reflux integrated biological reaction device is divided into two reaction areas and a separation area by the partition plate, the bottom of the front activated sludge area and the bottom of the rear biological filter area are respectively separated from the The bottom of the separation and precipitation area is connected, and a flap 10 is arranged inside the separation and precipitation area to divide the precipitation area into two parts. Such as image 3 As shown, the process flow is continuous water inflow and outflow. The raw water first enters the activated sludge section through the water inlet pipe 1, then flows around the sedimentation area of the inclined plate 12 and the folded plate 10, and then enters the packing layer of the biological filter, and finally passes through the outlet pipe 5 discharge. The lower part of the activated sludge section is equipped with an aeration...

Embodiment 2

[0027] Example 2: see Figure 4, the raw water first enters the activated sludge section through the water inlet pipe 1, then flows through the inclined plate sedimentation area and the folded plate, and then enters the packing layer of the biological filter, and finally is discharged through the outlet pipe 5. Close the aeration pipe 2, the activated sludge section is not aerated, and start the agitator 8, so that the activated sludge in this section is in a suspended state; the bottom of the activated sludge section is provided with a sludge discharge pipe 3, which is controlled by a valve and regularly discharged. At the same time, it also serves as an emptying pipe, which can drain the sewage in the activated sludge section when necessary; the biofilter section is equipped with an aeration pipe 7 near the bottom of the packing layer, and adopts continuous or intermittent aeration, and the DO is maintained at 2.0mg / L or more; when the filter is aerated, the water level can ...

Embodiment 3

[0028] Example 3 is mainly used for removing organic matter, suspended matter and denitrification and dephosphorization.

[0029] Embodiment 3: see image 3 , Figure 4 , the raw water first enters the activated sludge section through the water inlet pipe 1, then flows through the inclined plate sedimentation area and the folded plate, and then enters the packing layer of the biological filter, and finally is discharged through the outlet pipe 5. The activated sludge section and the filter section adopt alternate intermittent aeration, that is, when the activated sludge is aerated, the filter section is not aerated, and the schematic diagram of the water flow is as follows image 3 As shown; when the activated sludge section is not aerated, start the agitator to maintain the sludge in a suspended state. At this time, the filter section is aerated, and the water level of the filter section is raised by aeration, and the water level generated by the activated sludge section Po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com