Mild combustion chamber of gas turbine

A technology for gas turbines and combustors, applied in the direction of combustion chambers, continuous combustion chambers, combustion methods, etc., can solve problems such as difficulty in meeting the flue gas return requirements of combustion chambers, achieve safe and efficient operation, reduce oxygen concentration and peak flame temperature, and realize The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

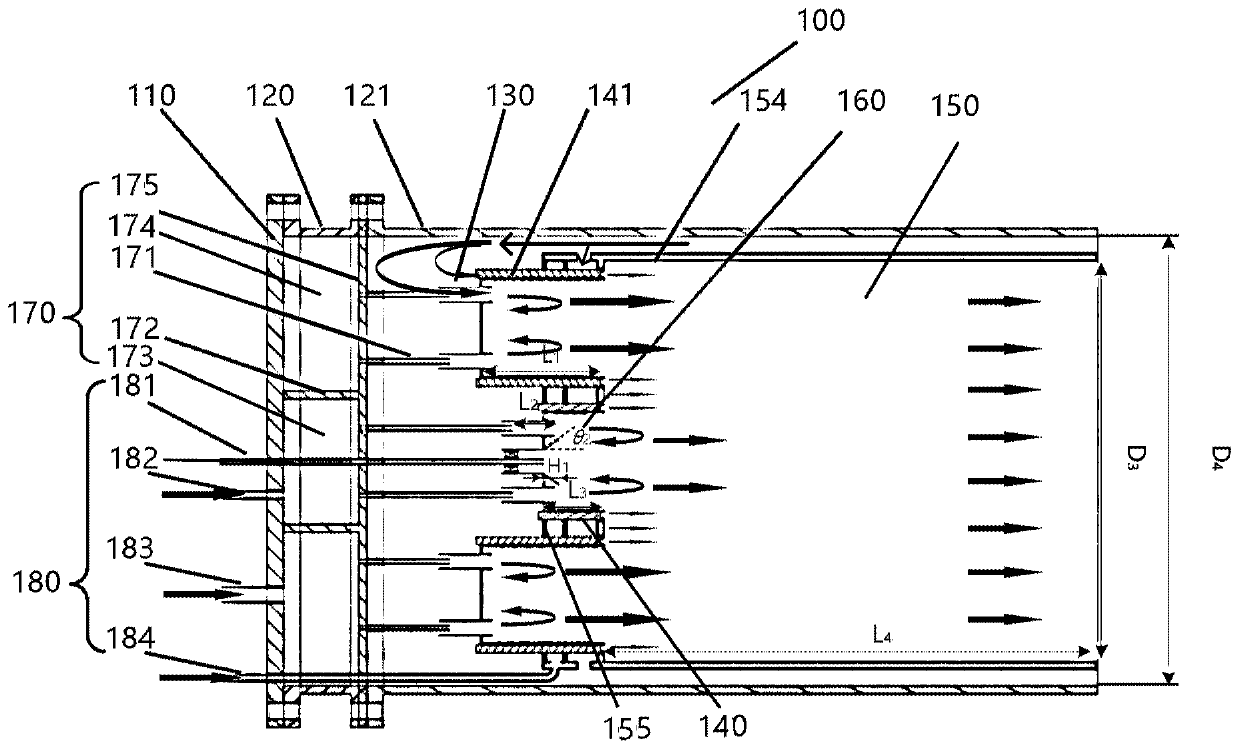

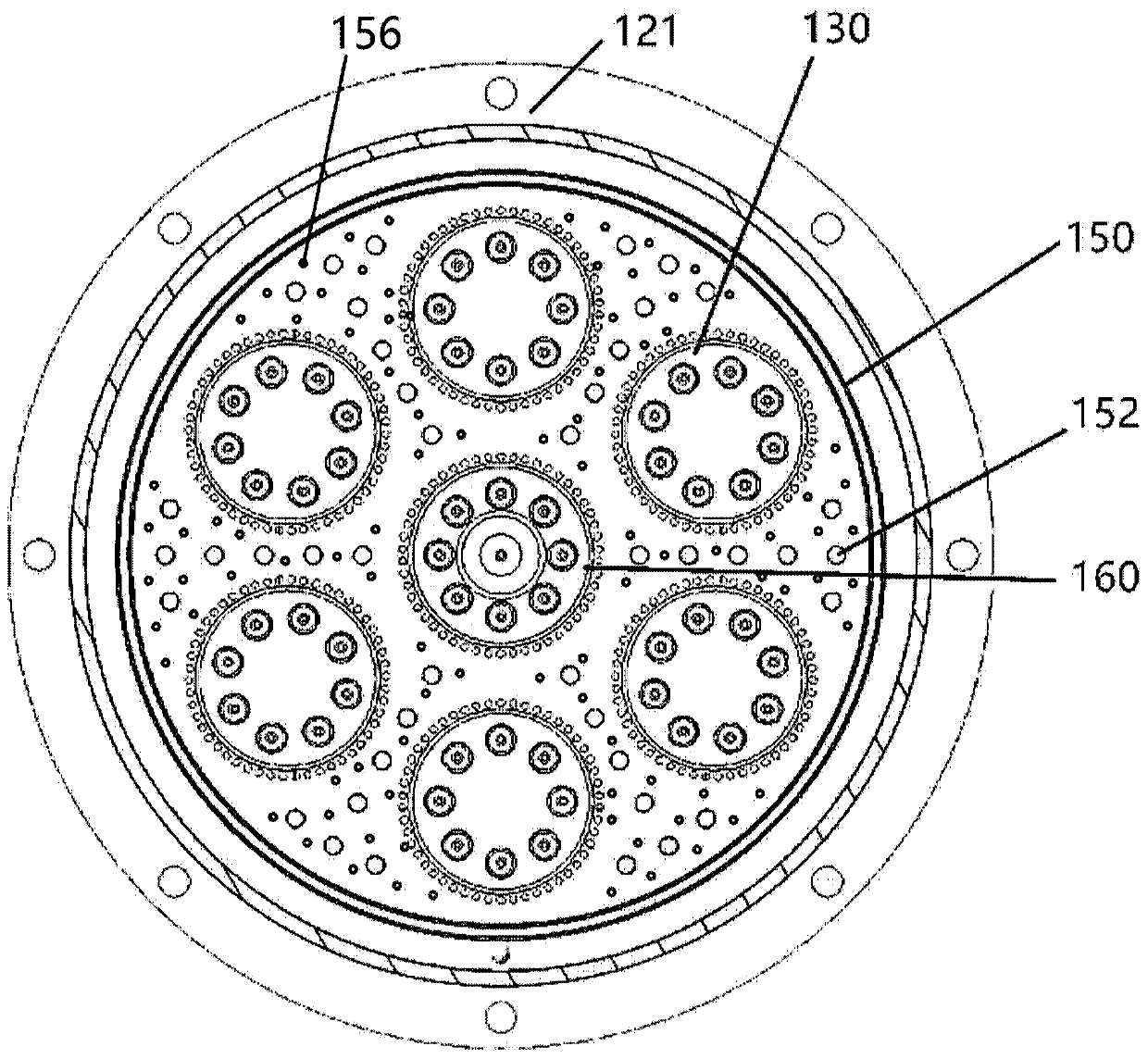

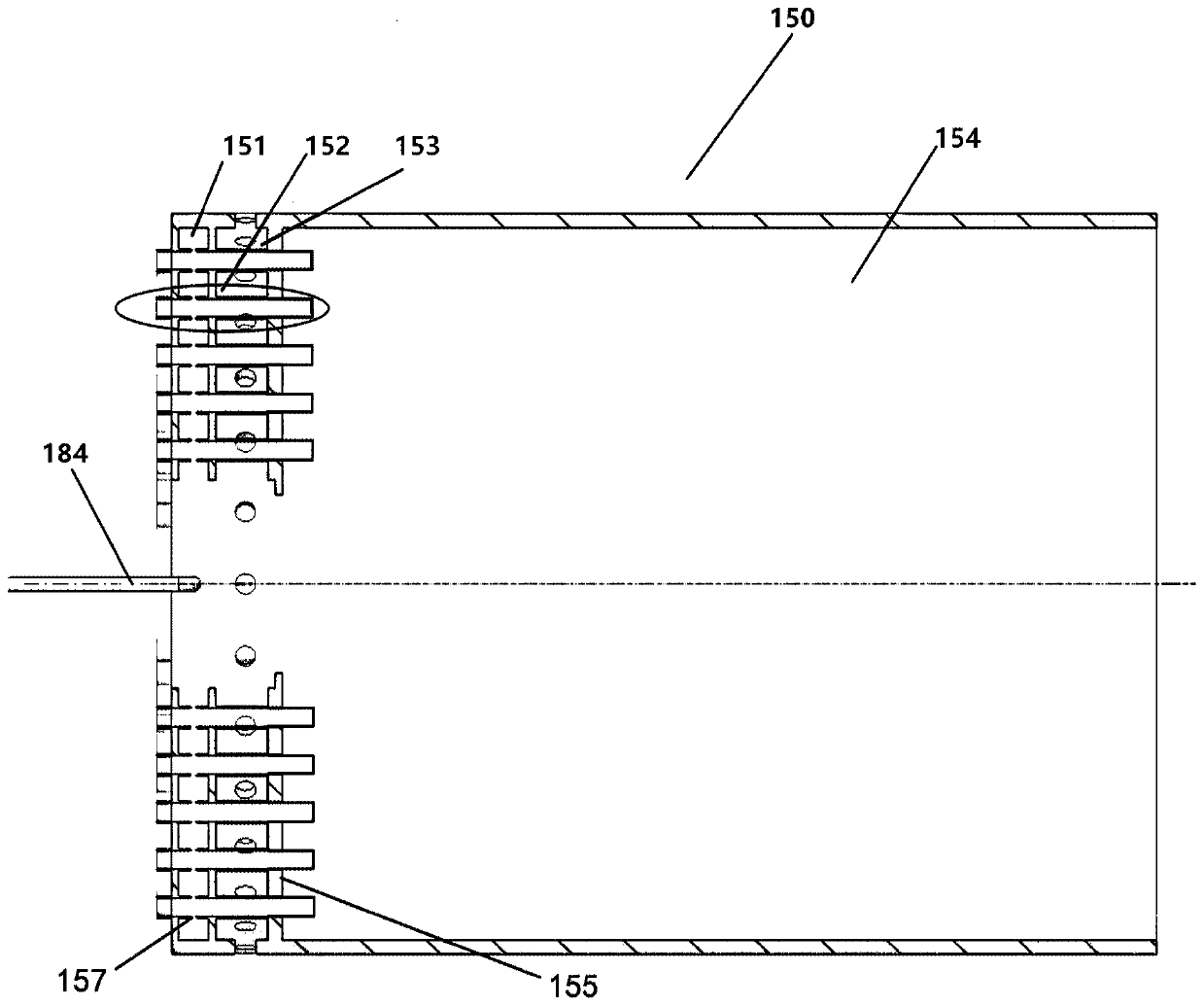

[0050] The invention makes full use of the characteristics of high-speed jet entrainment and backflow of a single soft burner (the soft burner is composed of a soft burner on duty and a premixed soft burner), and combines the array arrangement to make the flue gas, air and The blending of fuel is more uniform, and local soft combustion conditions are easier to establish. A full-area low-pressure drop backflow is formed inside the combustion chamber, and the high-temperature flue gas, cooling air, and micro-mixing nozzles of the soft burner are pre-mixed in the secondary combustion chamber. Further mixed combustion improves the temperature uniformity at the outlet of the soft combustion chamber of the gas turbine. The pre-mixed soft burner, the on-duty soft burner, and the micro-mixing nozzle have different axial positions, which realize fuel axial staging and stratified combustion, which is beneficial to the control of nitrogen oxide emissions. The use of swirl duty nozzles en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com