Method for grinding and scattering solid particles in liquid

A technology of solid particles and liquids, applied in the direction of mixing methods, chemical instruments and methods, mixers, etc., can solve the problems of particle agglomeration, poor effect, small quantity and strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

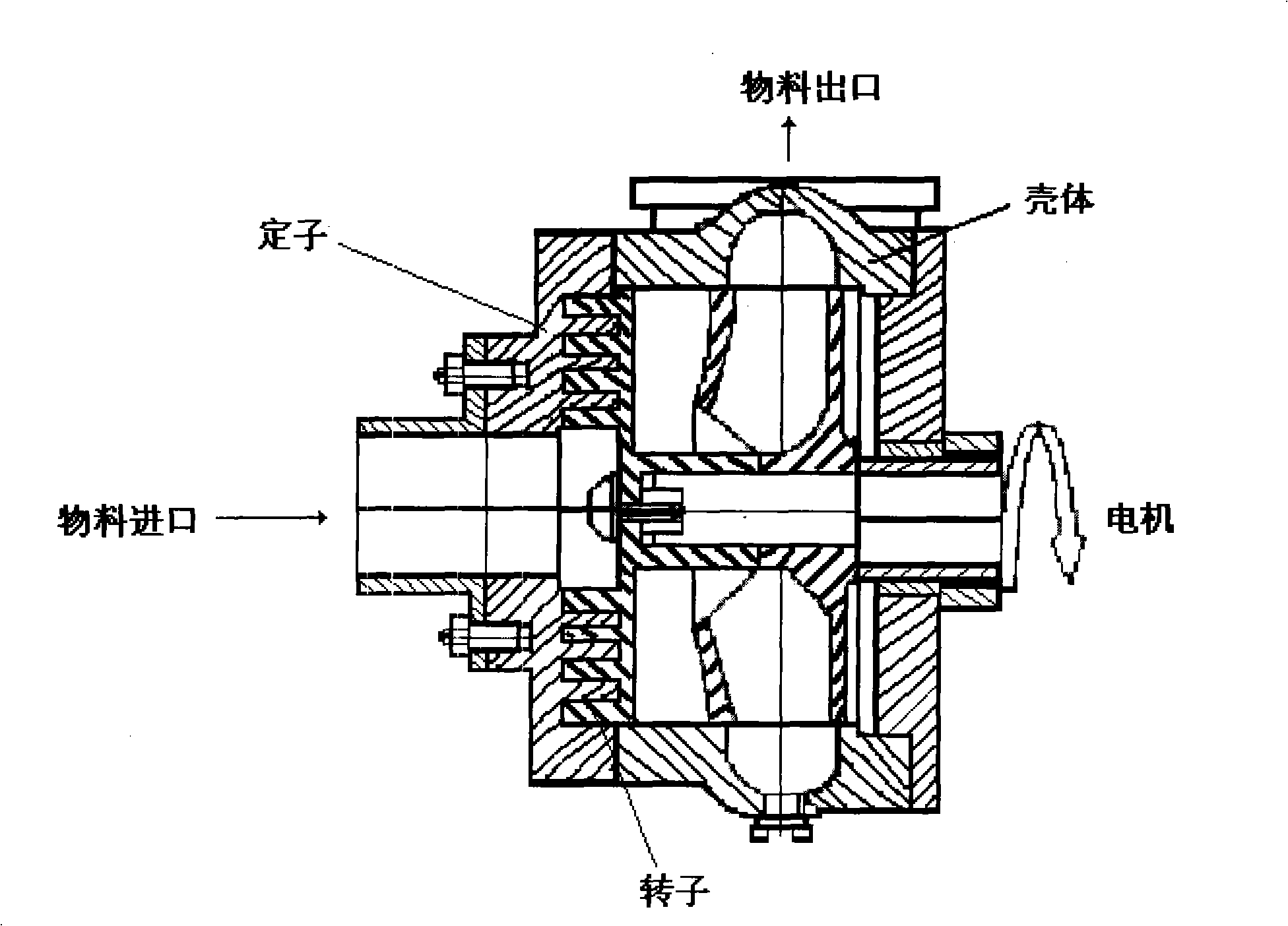

Image

Examples

example 1

[0008] Example 1: In the production of titanium dioxide, take 100 kilograms of titanium dioxide slurry before the sand mill, its solid content is 668g / L (TiO2), the average particle diameter D (0,9) of particle size distribution 90% is 49 μ m, add dispersant Sodium hexametaphosphate, the addition amount is 0.13%, pumped to the processing capacity of 10m under normal temperature 3 / h in the bubble generator, circulate for 2 minutes, and sample the effluent from the machine for analysis. Compared with the blank sample that did not enter the cavitation generator, the average particle size D(0,9) of 90% of the treated particle size distribution was 0.9 μm, and the particle size distribution did not change after 48 hours, while the blank sample showed obvious agglomeration after 5 minutes. The average particle diameter D(0,9) of 90% of the particle size distribution is 35 μm.

example 2

[0009] Example 2: Take 200 kilograms of common alkyd resin paint, which 100% passes through an 800 mesh sieve, and pump it to a processing capacity of 10m under normal temperature 3 In the cavitation generator of / h, the cycle operation is performed three times, and the effluent from the machine is sampled and analyzed, and its particle size is 100% through a 5000 mesh sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com