SCR denitration device and denitration method applicable to middle and small-size boilers

A technology for small and medium-sized boilers, which can be used in combination devices, separation methods, chemical instruments and methods, etc., can solve problems such as high fly ash concentration and catalyst wear, and achieve multi-functionality, compact structure, and rapid and effective separation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

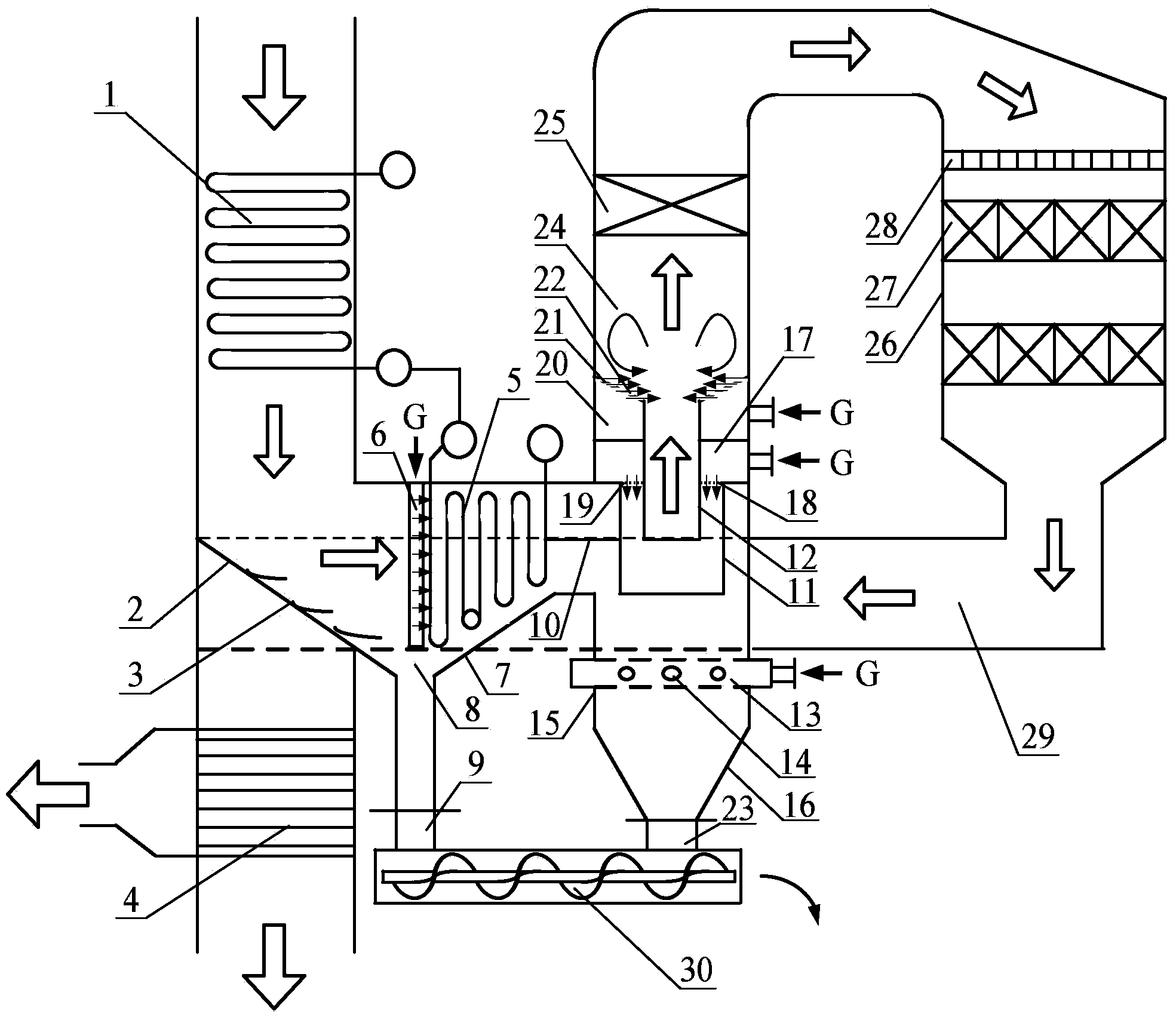

[0031] The implementation of the present invention will be described in detail below with reference to the accompanying drawings. This embodiment is carried out on the premise of this technical solution, and the detailed implementation and operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

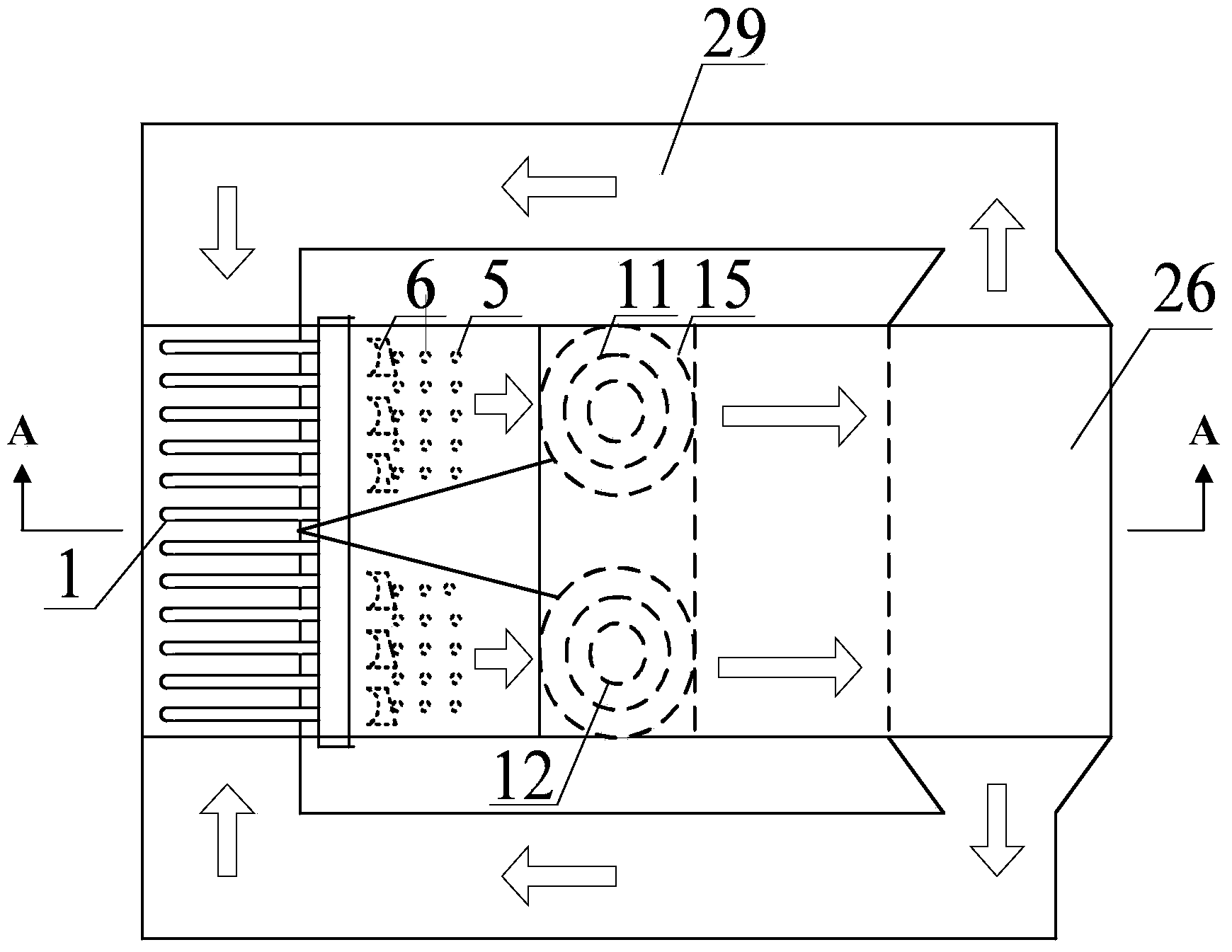

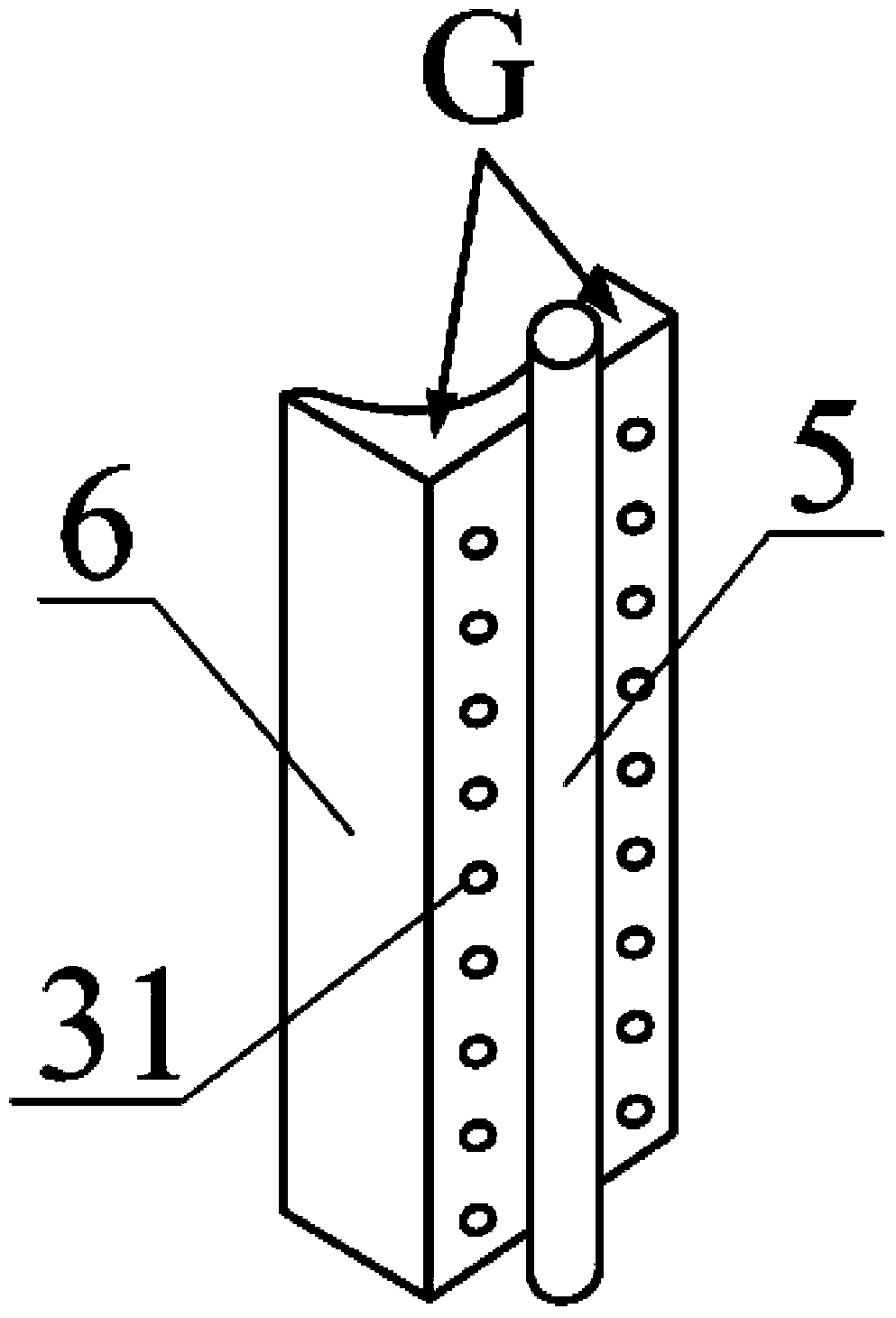

[0032] In this example, SCR denitrification technology transformation is carried out for a 170t / h power station coal-fired boiler. When the boiler is operating under rated conditions, the flue gas temperature after the high-temperature economizer in the tail flue is 385°C, and the NOx content is as high as 650mg / Nm 3 , dust content up to 3580mg / Nm 3 , The tail heating surface is arranged in a compact structure, and the distance between the economizer and the air preheater is only 1.2m. According to the characteristics of the flue gas parameters and the original structural characteristics of the boiler, this embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com